Hydration-resistant MgO-CaO series fireproofing material and preparation method thereof

A refractory material and hydration-resistant technology, which is applied in the field of refractory material production, can solve the problems of easy shedding of the coating layer, failure of hydration resistance, and difficult control, etc., to achieve improved mechanical properties and corrosion resistance, low production cost, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

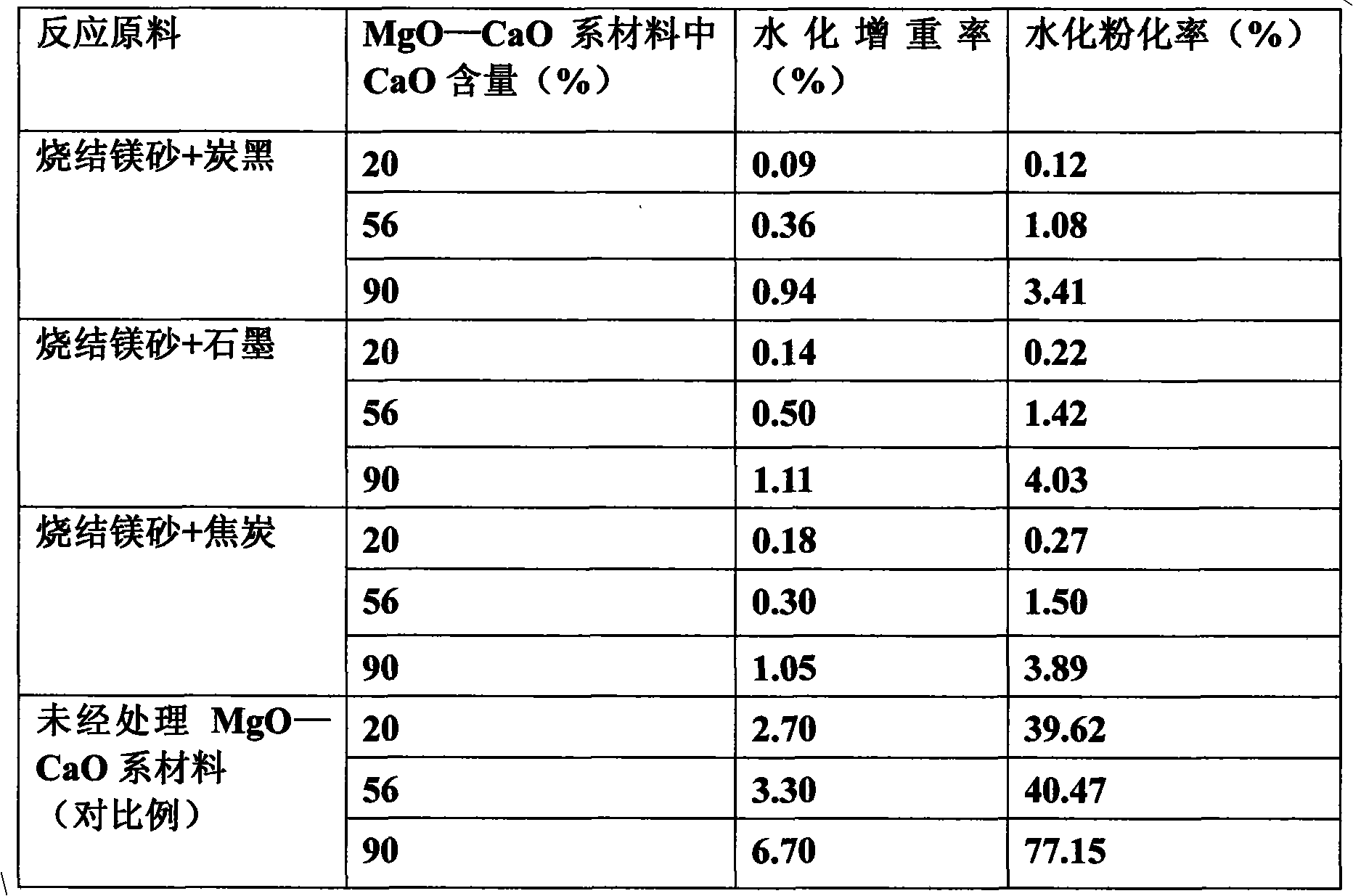

[0039] Mix 180-mesh magnesia with carbon black, 180-mesh graphite, and 180-mesh coke, respectively, according to the molar ratio of MgO and C of 1:1, and put two parts into the bottom of different reaction vessels, a total of six groups. MgO-CaO materials with CaO content of 20%, 56% and 90% and particle size of 2-4 mm are respectively put into reaction vessels filled with magnesia and carbon mixture. Put the reaction vessel into a controllable atmosphere furnace, vacuumize and fill with Ar for protection, and start to pass O 2 , O 2 The flow rate is 250 l / h, and the temperature is kept for 4 hours to obtain a hydration-resistant MgO-CaO-based refractory material.

[0040] Anti-hydration test: Take 50g of the treated MgO-CaO-based material with a particle size of 2-4mm and the untreated MgO-CaO-based material into a 100ml beaker, cover it with a watch glass, and put it in In a high-pressure steamer, under the condition of a pressure of 0.15MPa, keep warm for 2 hours, take ou...

Embodiment 2

[0047] 180 mesh magnesia and carbon black are uniformly mixed according to the molar ratio of MgO and C of 1:1 as the reaction raw material, and the MgO-CaO series materials are treated with three kinds of CaO content of 20%, 56% and 90%, respectively, heated to 1500 ° C, 1550 ° C °C, 1600 °C, 1650 °C and then heat preservation for 4 hours to obtain a hydration-resistant MgO-CaO refractory material. The hydration resistance data are shown in Table 2.

[0048] Table 2

[0049]

Embodiment 3

[0051] 180 mesh magnesia and carbon black are uniformly mixed according to the molar ratio of MgO and C of 1:1 as the reaction raw material, and the MgO-CaO series materials are treated with three kinds of CaO content of 20%, 56% and 90%. After 2 hours, 4 hours, 6 hours, and 8 hours, hydration-resistant MgO-CaO-based refractories were obtained, and the hydration-resistant data are shown in Table 3.

[0052] table 3

[0053]

[0054]

[0055] table 3

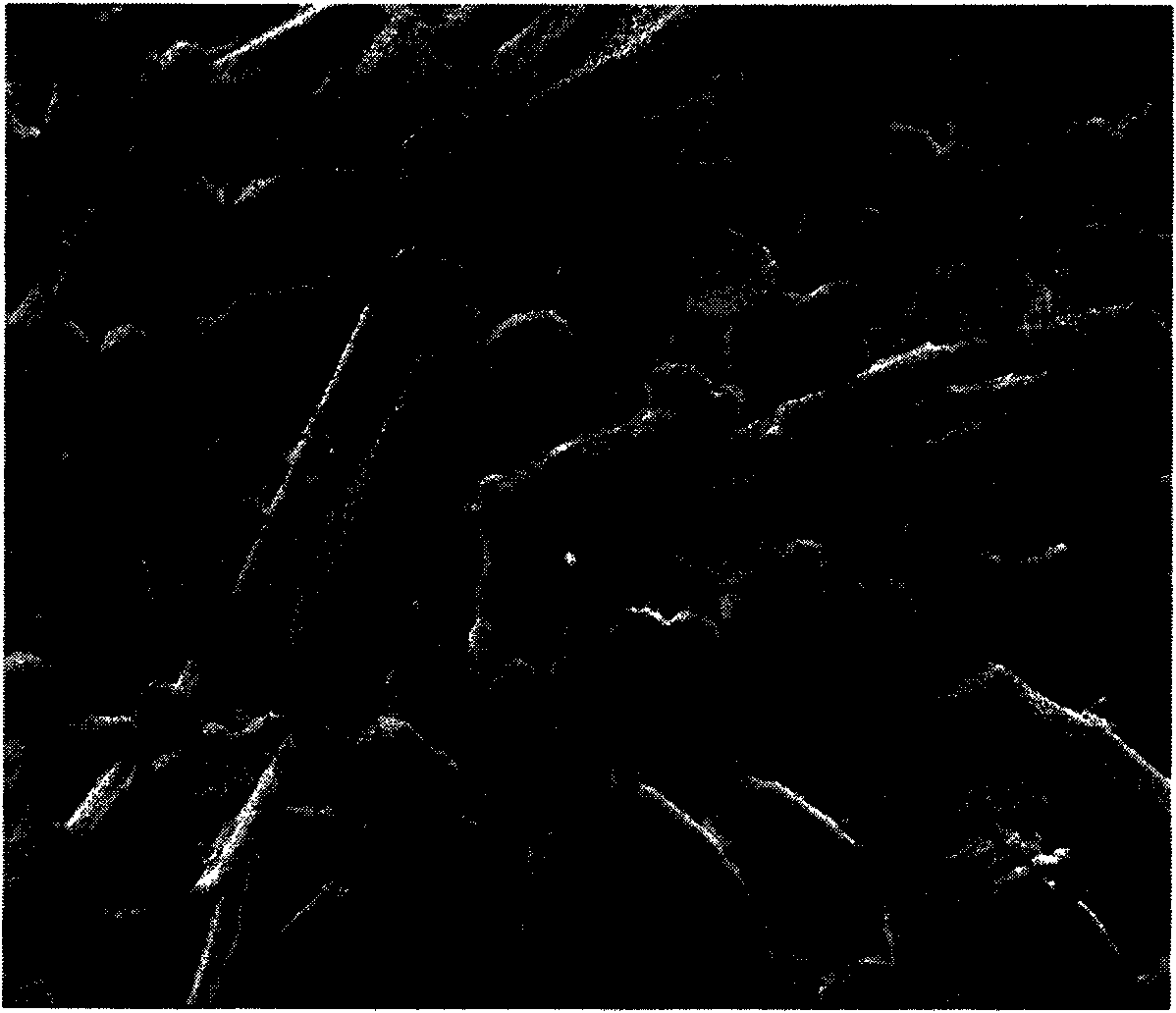

[0056] In the above examples, the surface morphology pictures of the prepared MgO-CaO-based refractories with a CaO content of 20% and the MgO-CaO-based refractories with a CaO content of 56% can be found in figure 1 and figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com