Production method and production equipment for high-purity polysilicon

A production method and technology for polycrystalline silicon, which are applied in the directions of polycrystalline material growth, crystal growth, and single crystal growth, etc., can solve problems such as being unsuitable for large-scale industrial production, difficult to layer oxides and silicon, and difficult to obtain high-purity polycrystalline silicon. , to achieve the effect of deep oxidation and impurity removal, compact structure and clear structure layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

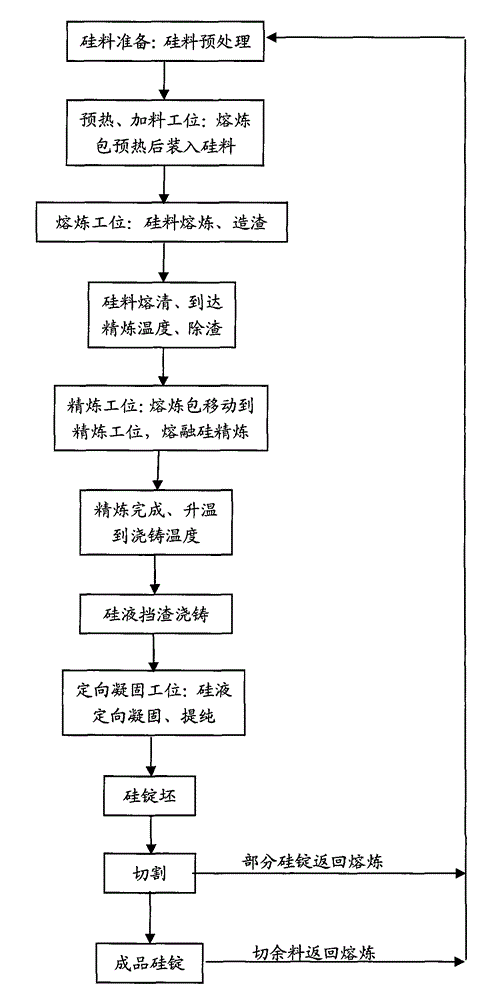

[0046] see figure 1 , which shows a preferred embodiment of the production method of the present invention. Firstly, the carbon-reduced metal silicon is used as the raw material, and the metal silicon is graded and crushed in a crusher, and then further crushed by a jet mill to make 150-400 mesh silicon powder. Then use the acid-dissolving method to remove oxides and some metal inclusions in the silicon, and then wash with deionized water and then dry. Weigh 25 tons of silicon powder according to the capacity of the 25-ton smelting furnace, put it in the feeding hopper, and prepare to add it to the smelting bag. The 25-ton smelting ladle is preheated before loading silicon materials. The preheating method is heated by burning heavy oil. The preheating temperature of the smelting ladle reaches 1500-1520°C. The preheating of the smelting ladle is carried out on the special preheating workbench of the production line. After preheating, the silicon material is added into the smel...

Embodiment 2

[0055] see also figure 1 , with carbon-reduced metal silicon as raw material, the metal silicon is graded and crushed in a crusher, and then further crushed by a jet mill to make 150-250 mesh silicon powder. Then the oxides and some metal inclusions in the silicon were removed by acid-dissolving method, and then washed with deionized water and then dried. Weighed 15 tons of silicon powder according to the capacity of a 15-ton smelting furnace, placed it in the feeding hopper, and prepared to add it to the smelting bag. The 15-ton smelting ladle is preheated before loading silicon materials. The preheating method is heated by burning heavy oil, and the preheating temperature of the smelting ladle reaches 1500°C. The preheating of the smelting ladle is carried out on the special preheating workbench of the production line. After preheating, the silicon material is added into the smelting ladle through the feeding hopper.

[0056] The smelting ladle containing the silicon materi...

Embodiment 3

[0065] see figure 1 , with carbon-reduced metal silicon as raw material, the metal silicon is graded and crushed in a crusher, and then further crushed with a jet mill to make 150-250 mesh silicon powder. Then the oxides and some metal inclusions in the silicon were removed by acid-dissolving method, and then washed with deionized water and then dried. Weighed 5 tons of silicon powder and put it into a 5-ton industrial frequency melting furnace.

[0066] Start power frequency induction heating, and assist in coal blowing oxygen combustion heating (fuel is liquefied petroleum gas, etc.), oxygen blowing combustion heating. Put the burning coal-oxygen gun on the surface of the silicon material, and the heat generated by the coal-oxygen combustion will melt the silicon. When the molten silicon forms a molten pool, turn off the gas and blow oxygen directly, so that the silicon at high temperature will be burned and released in the oxygen. Heat, continue to heat the silicon materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com