Marine oil-water separator and separation method thereof

An oil-water separator and boat technology, applied in separation methods, liquid separation, ships, etc., can solve the problems of large area, polluted water resources, complicated machine connection, etc., to save boat space, achieve effective utilization, The effect of uniform heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific drawings and embodiments.

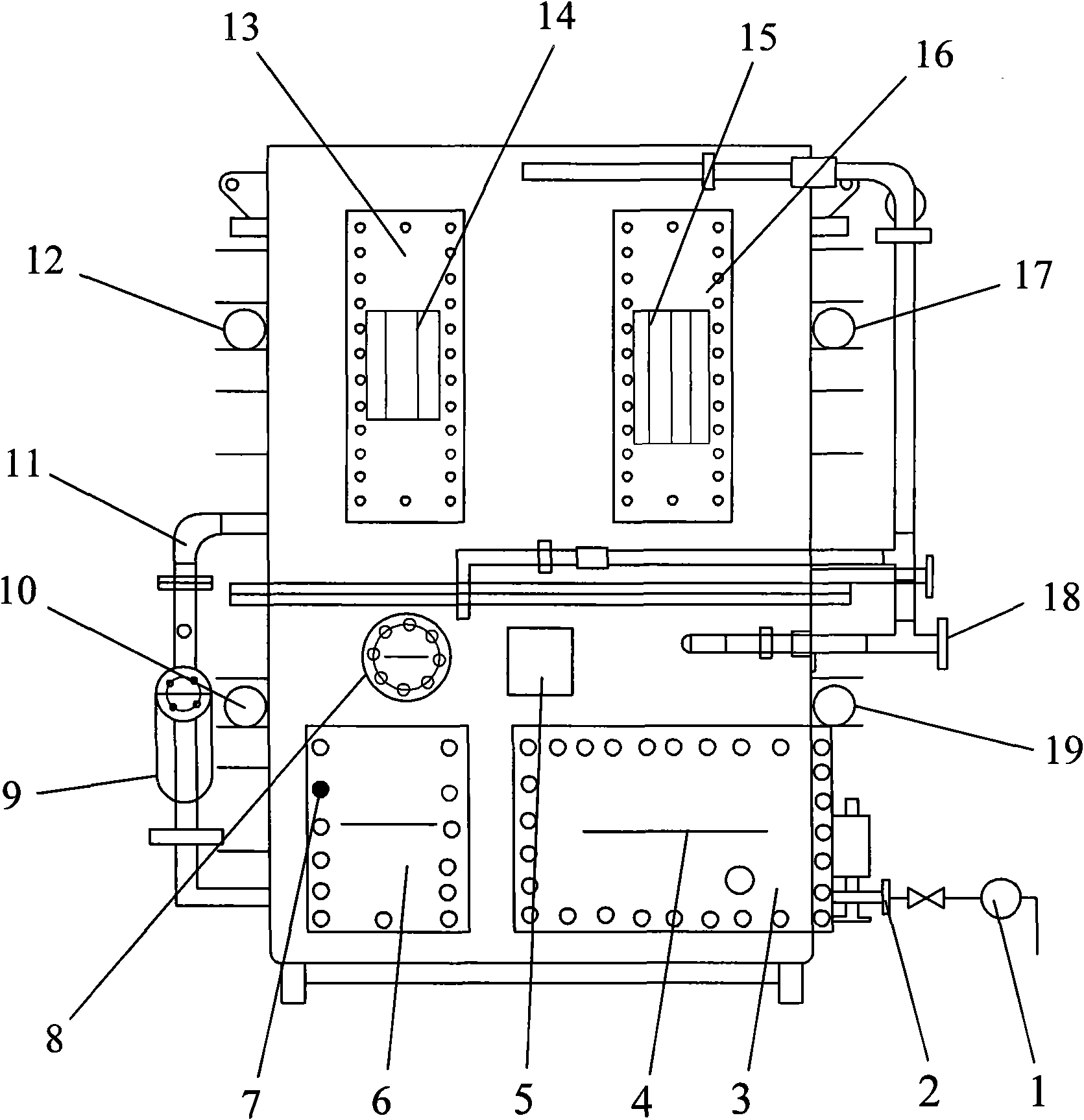

[0018] Such as figure 1 As shown, the boat oil-water separator includes a box body with an inlet 2 and an outlet 18 installed on the side wall, the box is divided into four separation chambers, the inlet 2 communicates with the first separation chamber 3, and the first separation chamber The cavity 3 is equipped with an advection Brown inclined plate 4, the bottom is provided with a slag discharge port, and the upper part is provided with an oil discharge port A, and the oil discharge port A is controlled by the sensor A19 and the solenoid valve A5 installed on the outer wall of the first separation chamber 3 Opening and closing: the first separation chamber 3 communicates with the second separation chamber 6, a steam heating demulsification device 8 and a solid emulsifying agent 7 are installed in the second separation chamber 6, and an oil discharge port B is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com