Metal surface treatment method

A surface treatment, metal technology, applied in metal material coating process, pressure inorganic powder coating, coating and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

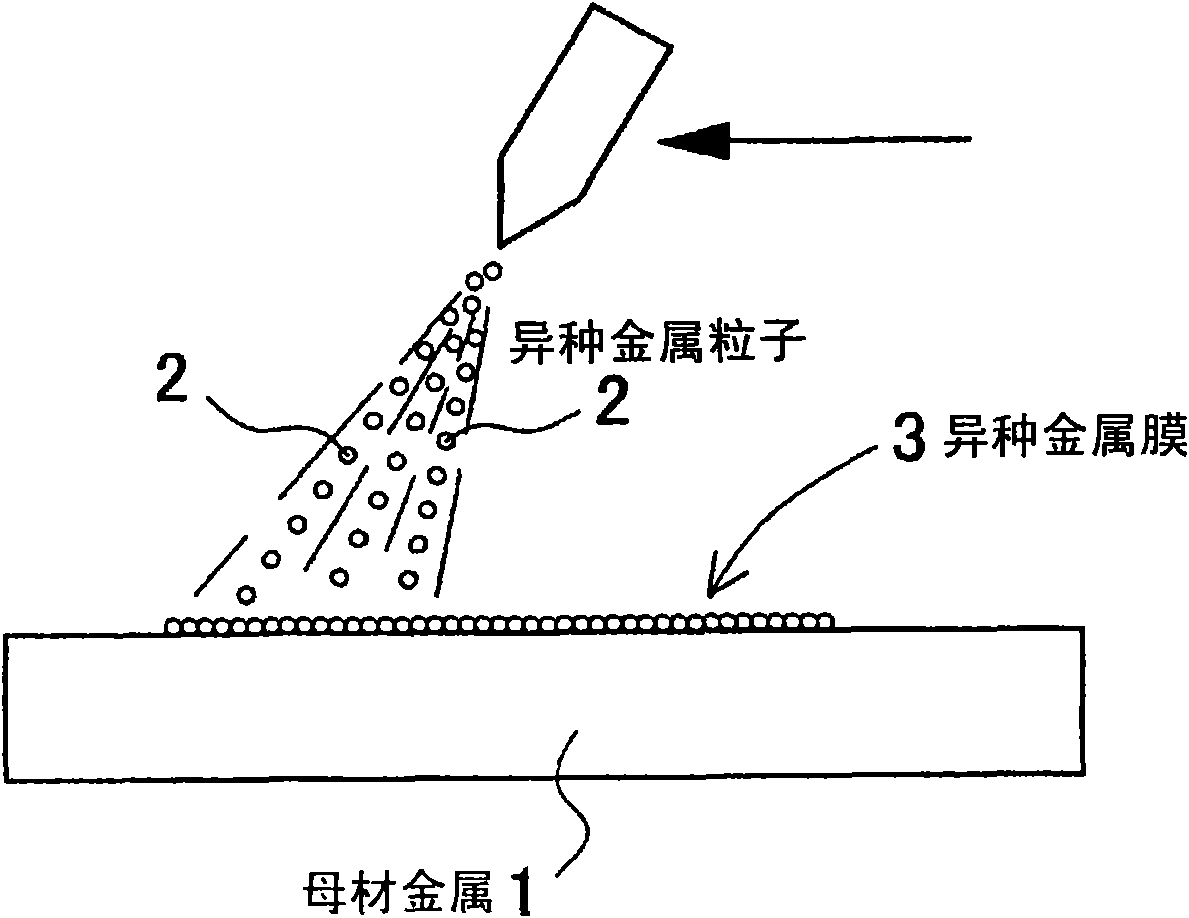

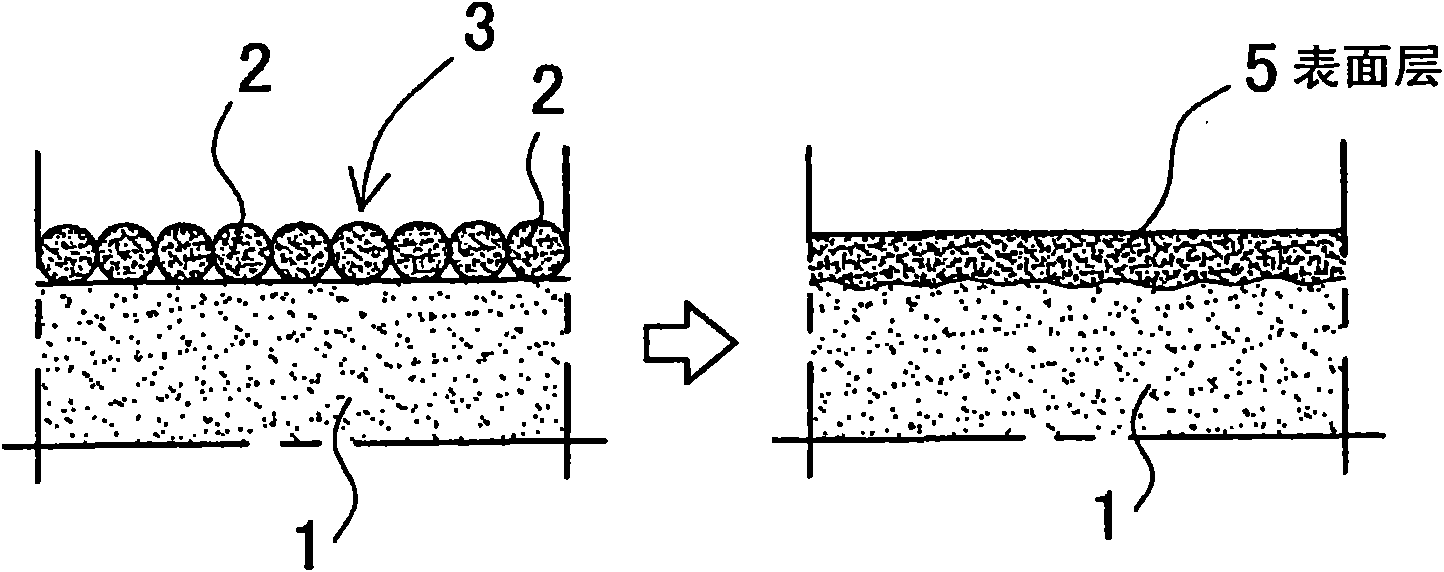

[0110] (1) Shot peening process

[0111] On the surface of pure copper or a copper alloy as a base metal 1, shot blasting is performed with dissimilar metal particles 2 composed of molybdenum disulfide. The average particle diameter of the dissimilar metal particles 2 was 10 μm, and the injection pressure of the shot blasting was 1 MPa. By this shot blasting, the dissimilar metal film 3 of molybdenum disulfide is formed on the surface of the base metal 1 .

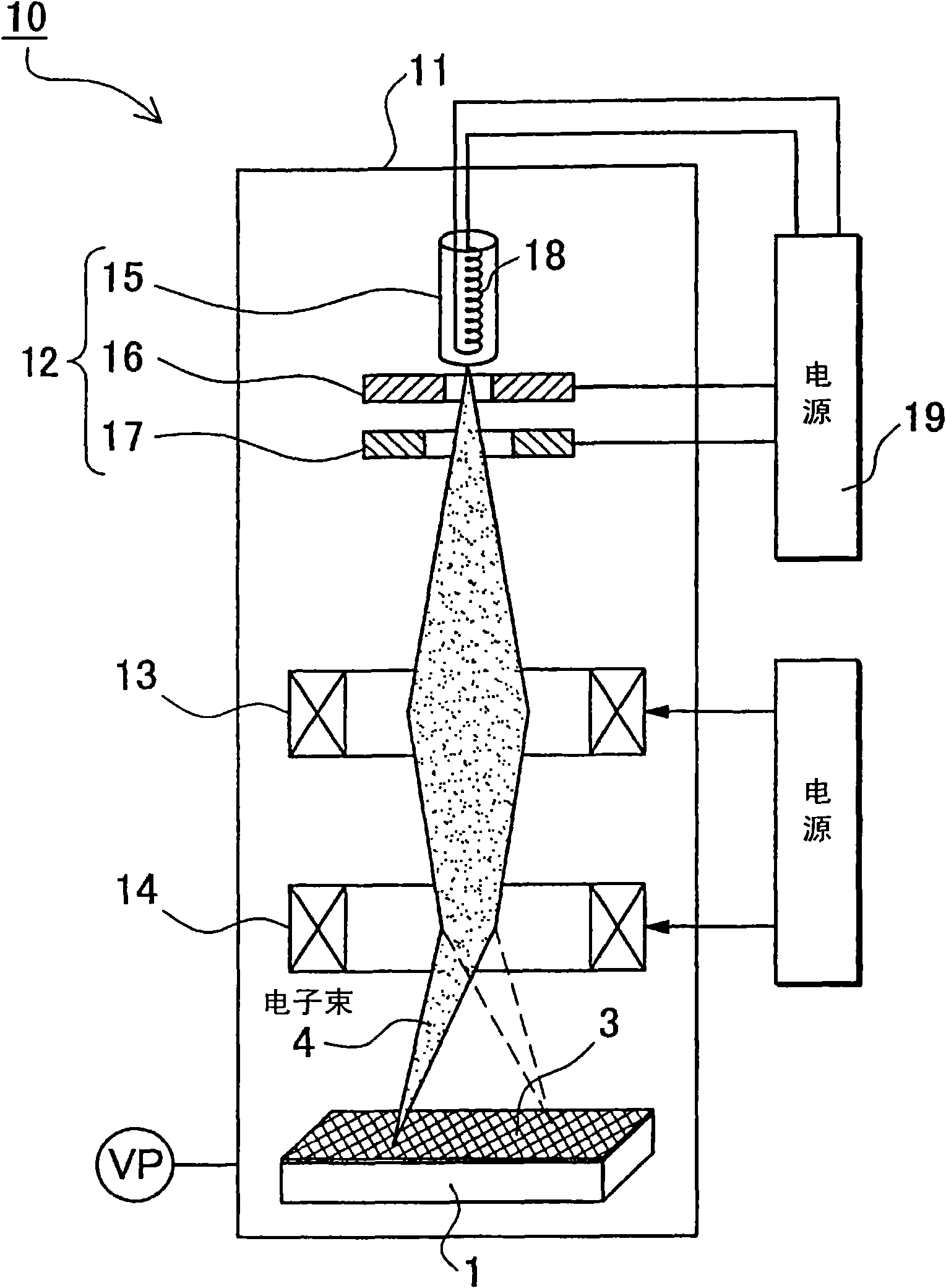

[0112] (2) Electron beam irradiation process

[0113] The base metal 1 having the dissimilar metal film 3 of molybdenum disulfide on its surface is placed in the sealed chamber 11, the sealed chamber 11 is evacuated to form a vacuum, and the surface of the base metal 1 is irradiated with an electron beam 4. Conditions for electron beam irradiation were set as follows. The vacuum degree of the airtight chamber 11 is 7 Pa or less.

[0114] Electron beam spot diameter 0.3mm

[0115] Acceleration voltage 30kV

[0116] Be...

Embodiment 2

[0122] (1) Shot peening process

[0123] Shot peening is performed on the Ti surface of the base metal 1 with tungsten dissimilar metal particles 2 . The average particle diameter of tungsten as the dissimilar metal particles 2 was 20 μm, and the injection pressure of the shot blasting was 1 MPa. By this shot blasting, the dissimilar metal film 3 of tungsten is formed on the surface of the base metal 1 .

[0124] (2) Electron beam irradiation process

[0125] A base metal 1 having a tungsten dissimilar metal film 3 on its surface is placed in a sealed chamber 11, the sealed chamber 11 is evacuated to form a vacuum, and the surface of the base metal 1 is irradiated with an electron beam 4. Conditions for electron beam irradiation were set as follows. The vacuum degree of the airtight chamber 11 is 7 Pa or less.

[0126] Electron beam spot diameter 0.3mm

[0127] Acceleration voltage 30kV

[0128] Beam current 110mA

[0129] The scanning area of the electron beam is 30m...

Embodiment 3

[0134] (1) Shot peening process

[0135] SKD-11 was used as the base metal 1, and shot blasting was performed with dissimilar metal particles 2 made of SiC. The average particle diameter of the dissimilar metal particles 2 was 3 μm, and the injection pressure of the shot peening was 1 MPa. By this shot blasting, the SiC dissimilar metal film 3 is formed on the surface of the base metal 1 .

[0136] (2) Electron beam irradiation process

[0137] A base metal 1 having a SiC dissimilar metal film 3 on its surface is placed in a sealed chamber 11 , the sealed chamber 11 is evacuated to form a vacuum, and the surface of the base metal 1 is irradiated with an electron beam 4 . Conditions for electron beam irradiation were set as follows. The vacuum degree of the airtight chamber 11 is 7 Pa or less.

[0138] Electron beam spot diameter 0.3mm

[0139] Acceleration voltage 30kV

[0140] Beam current 100mA

[0141] The scanning area of the electron beam is 30mm×30mm

[0142] S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com