Micron single crystal granular anode material of lithium ion battery

A technology for lithium-ion batteries and cathode materials, applied in battery electrodes, alkaline storage batteries, circuits, etc., can solve the problem that cathode active materials cannot meet the requirements of producing large-capacity or high-power lithium-ion batteries, self-discharge reversible capacity decay, reduce Cathode material specific capacity and other issues, to achieve the effect of improving cycle life and high power output performance, reducing obstacles, and improving high-rate charge-discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 50 kg of manganese and aluminum composite oxide precursor MnO 2 -Al 2 o 3 (Mn:Al=1.85:0.15) and 11 kg Li 2 CO 3 Thoroughly grind and mix, then pre-sinter at 450°C for 5 hours, then heat up to 950°C and sinter at high temperature for 24 hours, and finally cool down to room temperature slowly.

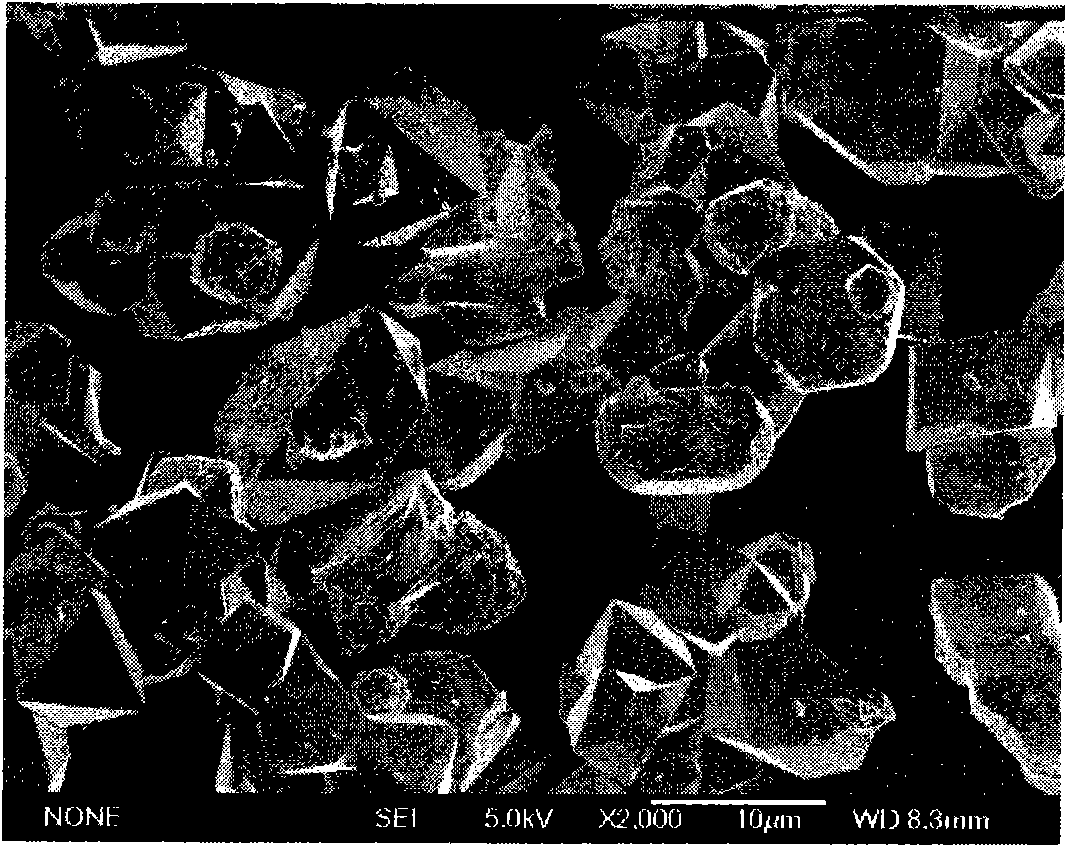

[0027] The particle size and morphology of the materials were observed on a Hitachi S-4000 scanning electron microscope. From figure 1 We can find that the new modified lithium manganese oxide we prepared is a single crystal particle, presenting a perfect regular octahedron, the grain size is about 5-10 microns, the particle size is uniform, and the surface is smooth.

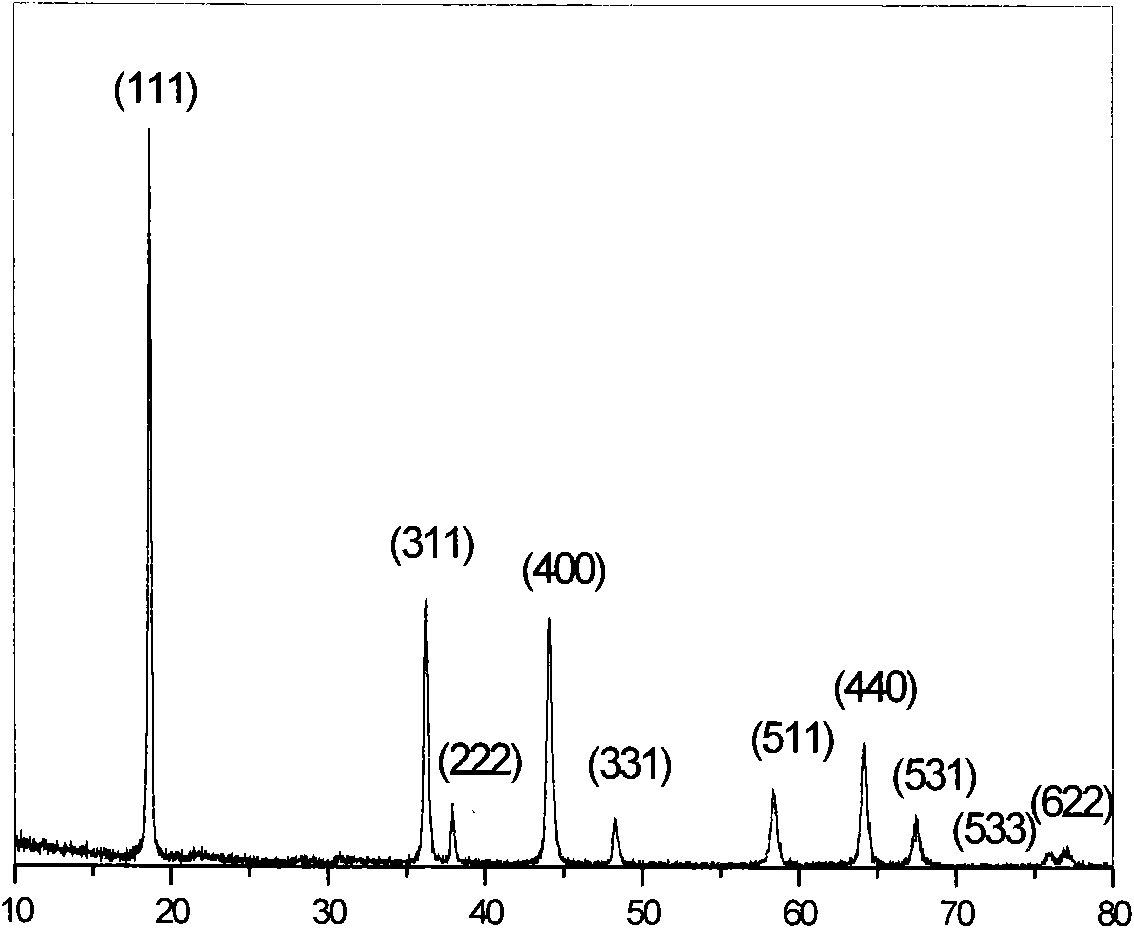

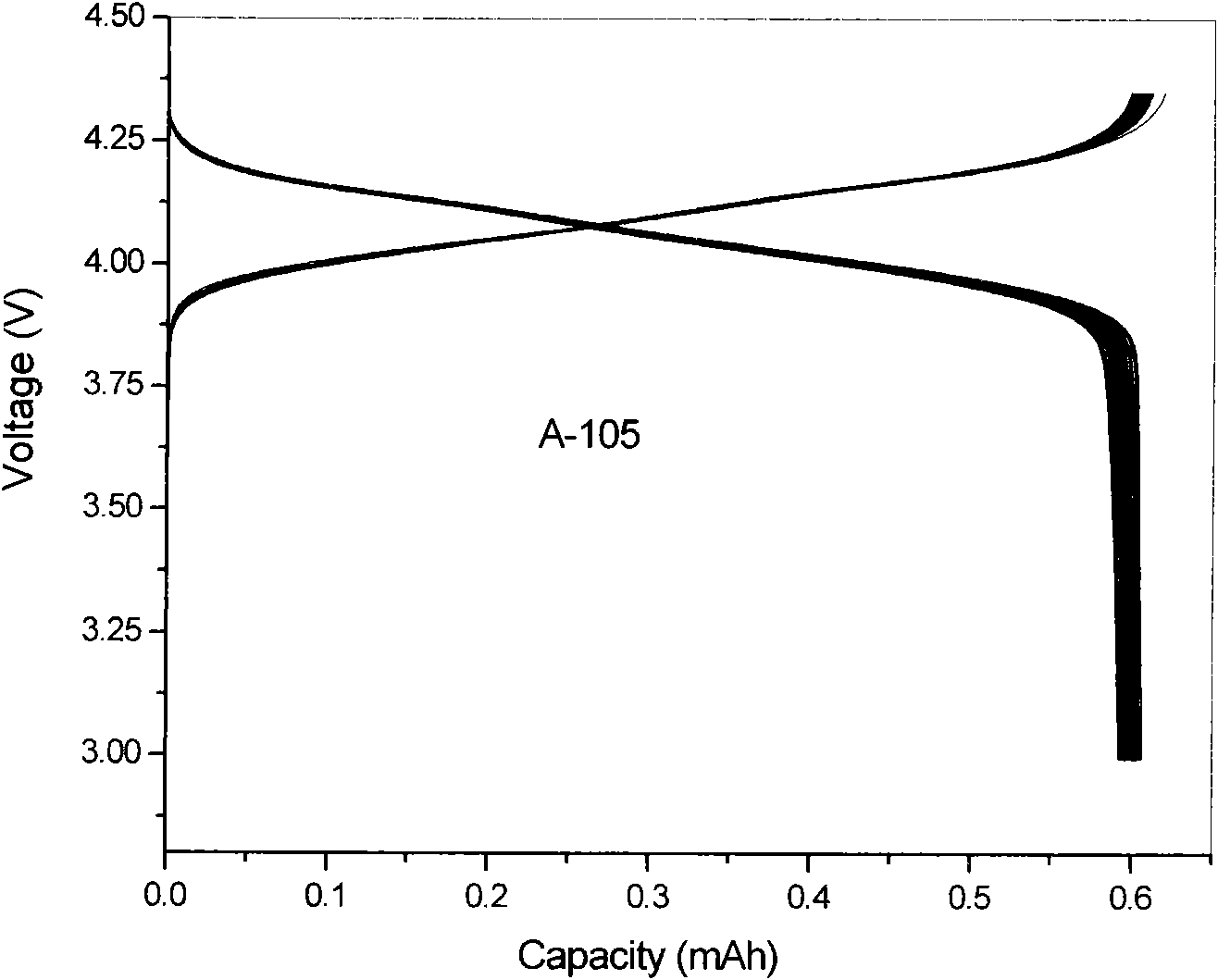

[0028] The crystal structure of the material was analyzed using a Rigaku B / Max-2400 X-ray diffractometer (Rigaku Ltd.), with Cu Kα line as the light source, and the diffraction angle 2θ ranged from 10° to 90°. From figure 2 We can find that the synthetic material has a standard cubic structure of normal spi...

Embodiment 2~10

[0034] Synthesize a series of positive spinel structure lithium manganese oxide LiMn under different conditions according to the preparation method of the present invention 2-z m z o 4 positive active material

[0035] According to the preparation method provided by the invention, under the different conditions listed in table 1, a series of positive spinel structure lithium manganese oxide LiMn were synthesized 2-z m z o 4 positive active material.

[0036] Table 1

[0037] Example

Embodiment 11

[0039] 50 kg of manganese and aluminum composite oxide precursor Mn 3 o 4 -Al 2 o 3 (Mn:Al=1.8:0.2) and 12 kg Li 2 CO 3 Fully grind and mix, then pre-sinter at 400°C for 8 hours, then heat up to 850°C and sinter at a high temperature for 24 hours, and finally cool slowly to room temperature to synthesize the required positive spinel manganese-containing cathode active material for lithium-ion batteries.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com