Elastic colorized printing paste and production method thereof

A technology of printing paste and elasticity, which is applied in the fields of dyeing, textiles and papermaking, etc. It can solve the problems of unsatisfactory use effect and no technical disclosure information, etc., and achieve the effect of improving gloss, good elasticity and improving smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Emulsification: Add 20 grams of itaconic acid, 350 grams of ethyl acrylate, 71 grams of allyl polyoxyalkyl epoxy ether, γ-methacryloxypropyl trimethoxysilane into a stainless steel kettle 10 grams, 42 grams of methyl methacrylate, 2 grams of fatty alcohol polyoxyethylene ether XL-90, 550 grams of deionized water, stirred and emulsified for 20 minutes to prepare an emulsion.

[0020] (2) Initiate the polymerization reaction: get 20% of the total amount of the emulsion, i.e. 209 grams, add in the reactor, heat up to 80-82 ° C, add the mixed solution of 1.27 grams of initiator ammonium persulfate and 50 grams of water, and initiate. At this temperature, 836 grams of the remaining emulsion was added dropwise, and at the same time, a mixture of 0.63 grams of ammonium persulfate and 50 grams of water was added dropwise. -40°C, adjust the pH value to 7±0.5 with ammonia water;

[0021] (3) Compounding: add 300-310 grams of superfine aluminum silicate, stir evenly, filter a...

Embodiment 2

[0023] The weight ratio of raw materials is: 20.5 grams of itaconic acid, 355 grams of ethyl acrylate, 72 grams of allyl polyoxyalkyl epoxy ether, 10.5 grams of γ-methacryloxypropyl trimethoxysilane, methyl 43 grams of methyl acrylate, 2.1 grams of fatty alcohol polyoxyethylene ether XL-90, 2.1 grams of ammonium persulfate, 580 grams of deionized water, and 310 grams of superfine aluminum silicate. The process of production is the same as in Example 1.

Embodiment 3

[0025] The weight ratio of raw materials is: 21 grams of itaconic acid, 360 grams of ethyl acrylate, 73 grams of allyl polyoxyalkylene epoxy ether, 10.5 grams of γ-methacryloxypropyl trimethoxysilane, methyl 4 grams of methyl acrylate, 2.0 grams of fatty alcohol polyoxyethylene ether XL-90, 2.1 grams of ammonium persulfate, 600 grams of deionized water, 310 grams of superfine aluminum silicate, the technological process of production is the same as embodiment 1.

[0026] The using method of elastic color printing paste of the present invention:

[0027] Take this product and add the required paint color paste, stir evenly, and then it can be used for printing.

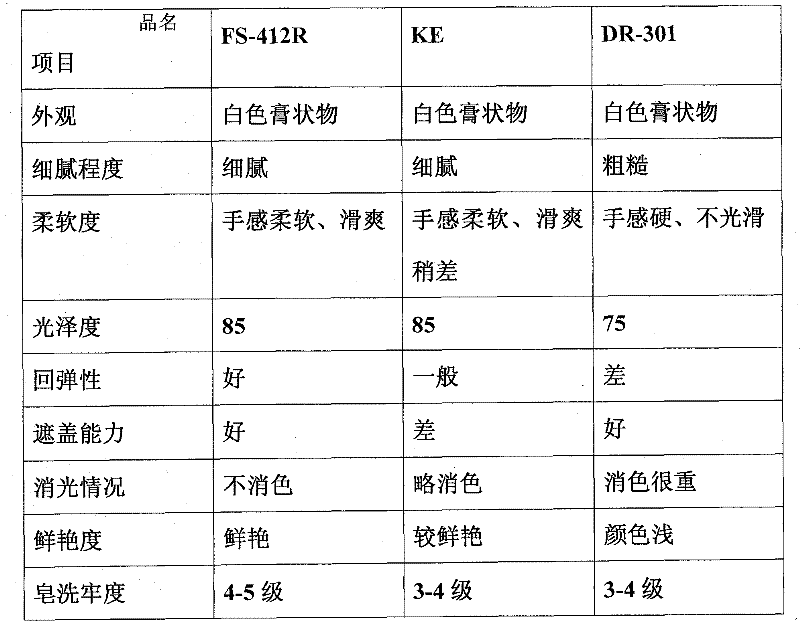

[0028] This product (hereinafter referred to as FS-412R) is compared with representative similar products on the market: KE products of Ningbodi Company and domestic DR-301 products:

[0029]

[0030] 1. Soaping process: 5 g / L soap powder, 2 g / L soda ash, boil at 60°C for 30 minutes.

[0031] 2. Gloss: WGG digital...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com