Nickel palladium/ silicon microchannel catalyst and application thereof on preparing electrode of integratable direct methanol fuel cell

A silicon microchannel, catalyst technology, applied in catalyst activation/preparation, battery electrodes, physical/chemical process catalysts, etc., can solve problems such as unfavorable direct methanol fuel cell preparation, and achieve the avoidance of poisoning phenomenon, good catalytic activity, and porosity. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

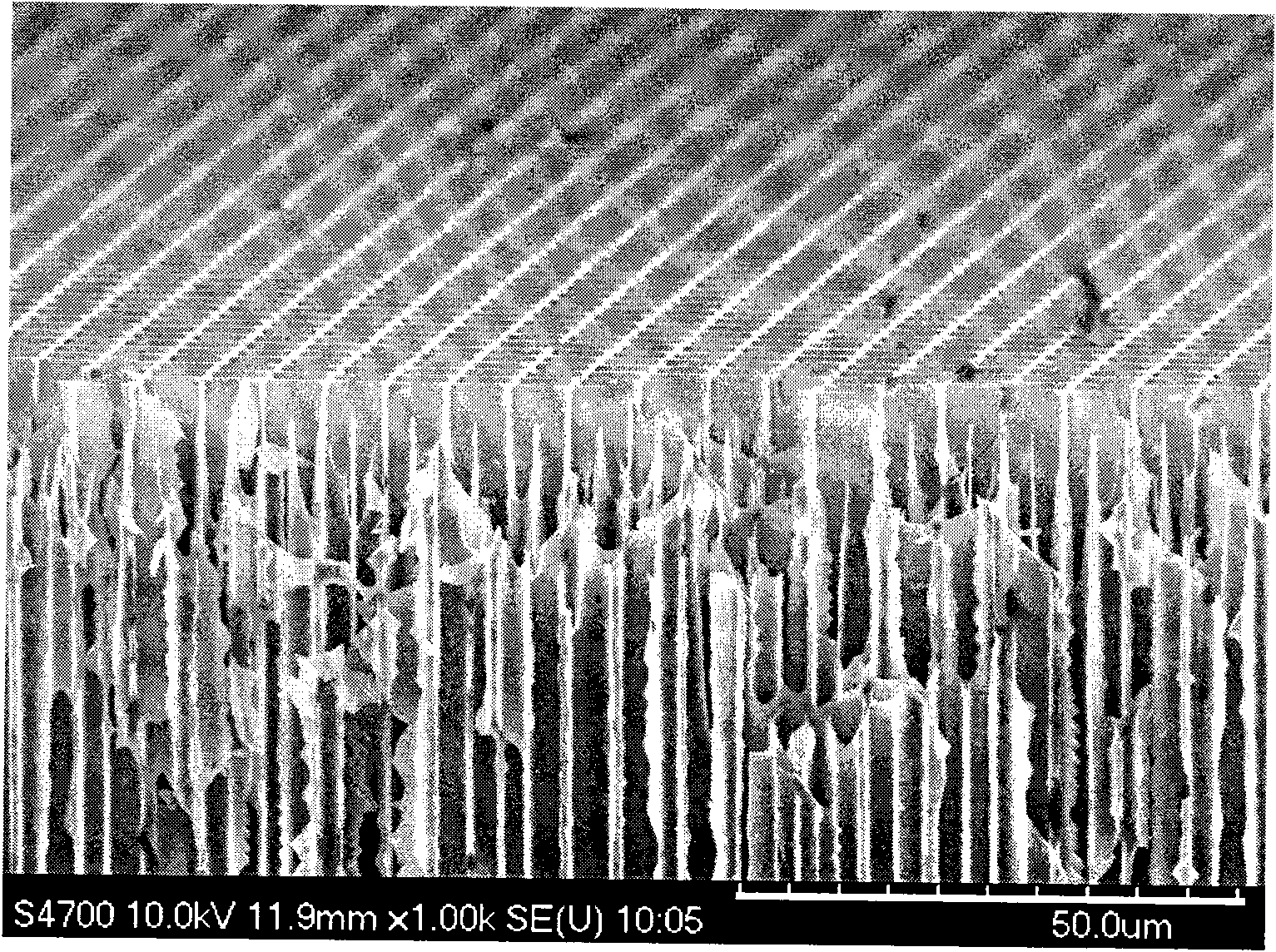

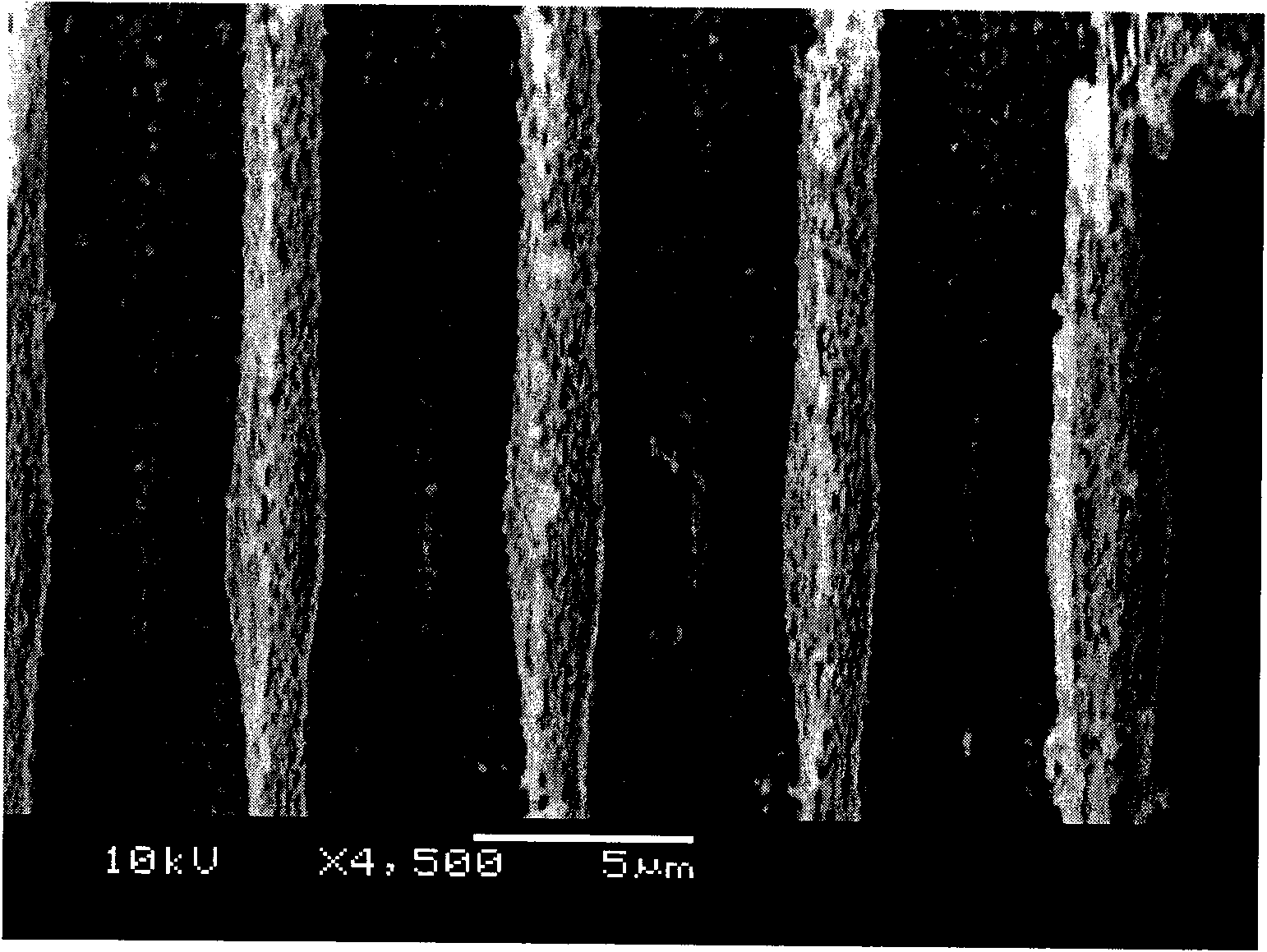

[0031] The fabrication process of electrochemical corrosion microchannels based on MEMS technology has been described in detail in patent application 200610025900. The microchannel hole is a square with a side length of 5 microns, a wall thickness of 1 micron, and a depth of 250 microns. The etched silicon microchannel SEM photo is as follows figure 1 shown.

[0032] 1. Preparation of silicon microchannels:

[0033] The fabrication process of electrochemical corrosion microchannels based on MEMS technology has been described in detail in patent application 200610025900. The microchannel hole is a square with a side length of 5 microns, a wall thickness of 1 micron, and a depth of 250 microns. The etched silicon microchannel SEM photo is as follows figure 1 As shown, the depth of etching can be controlled by etching time.

[0034] 2. Preparation of nickel-palladium / silicon microchannel catalyst

[0035] Wash the silicon microchannel with 1% to 5% HF solution, use the sili...

Embodiment 2

[0045] 1. Fabrication of silicon microchannels: The fabrication process of electrochemical corrosion microchannels based on MEMS technology has been described in detail in patent application 200610025900. The microchannel hole is a square with a side length of 5 microns, a wall thickness of 1 micron, and a depth of 250 microns. The etched silicon microchannel SEM photo is as follows figure 1 As shown, the depth of etching can be controlled by etching time.

[0046] 2. Preparation of nickel-palladium / silicon microchannel catalyst

[0047] Wash the silicon microchannel with 1% to 5% HF solution, use the silicon microchannel as the substrate, and use the electroless plating solution to electrolessly deposit nickel-palladium film on the inner surface of the silicon microchannel, the reaction time is 40 minutes, and the reaction temperature is 80 -85°C, the pH of the electroless plating solution is adjusted to 8.0 with ammonia water, the composition includes:

[0048] NiSO 4 .6...

Embodiment 3

[0055] 1. Preparation of silicon microchannels: The fabrication process of electrochemical corrosion microchannels based on MEMS technology has been described in detail in patent 200610025900. The microchannel hole is a square with a side length of 5 microns, a wall thickness of 1 micron, and a depth of 250 microns. The etched silicon microchannel SEM photo is as follows figure 1 As shown, the depth of etching can be controlled by etching time.

[0056] 2. Preparation of nickel-palladium / silicon microchannel catalyst

[0057] Wash the silicon microchannel with 1% to 5% HF solution, use the silicon microchannel as the substrate, and use the electroless plating solution to electrolessly deposit nickel-palladium film on the inner surface of the silicon microchannel, the reaction time is 30 minutes, and the reaction temperature is 80 -85°C, the pH of the electroless plating solution is adjusted to 8.0 with ammonia water, the composition includes:

[0058] NiSO 4 .6H 2 O 1.5M ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com