Active ecological wood floor and manufacturing method thereof

A manufacturing method and technology of ecological wood, applied in building structure, floor, building, etc., can solve the problems of coating film-forming effect, poor transparency, poor negative ion ability, and inability to be effectively exposed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

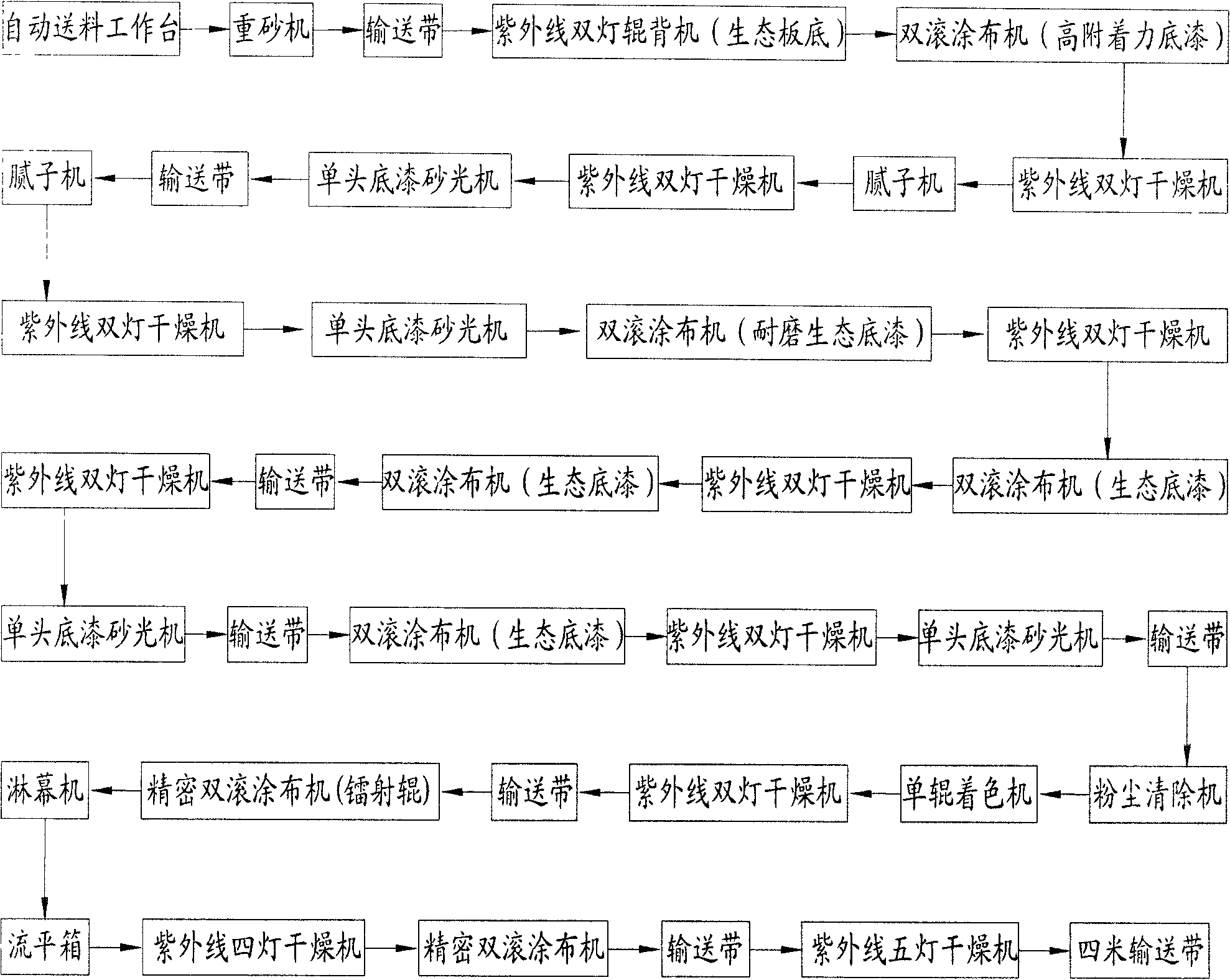

Image

Examples

Embodiment Construction

[0066] The active ecological wood floor and its manufacturing method of the present invention will be further described in detail below in conjunction with specific examples.

[0067] 1. Preparation of active ecological UV paint

[0068] 1.1 Main raw materials

[0069] Component A: epoxy acrylic resin, aliphatic polyurethane, TMPTA (trimethylol acrylate), DPGDA (dipropylene glycol diacrylate)

[0070] Component B: HEA (hydroxyethyl acrylate), talcum powder, photoinitiator (1173, 651, benzophenone), leveling agent (BYK 307), polymerization inhibitor

[0071] C component: Negative ion powder.

[0072] 1.1.2 Preparation of surface coating

[0073] Raw material name

[0074] First add component A to the high-speed disperser in turn, and stir for 5 minutes; add component B to material A in turn, and stir for 15 minutes; then add component C to the above-mentioned mixture of A and B, and stir for 10 minutes; vacuumize for 10 minutes. .

[0075] 1.2.2 Preparation of pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com