Ultraviolet light solidified glue film glass

A technology of ultraviolet light and curing glue, which is applied in the field of glass, can solve the problems of unstable quality of handmade glass film, scattered and injured people, and low production efficiency, so as to solve the problem of scattered and injured people, improve the anti-shattering performance, and improve the thermal insulation performance and the effect of weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

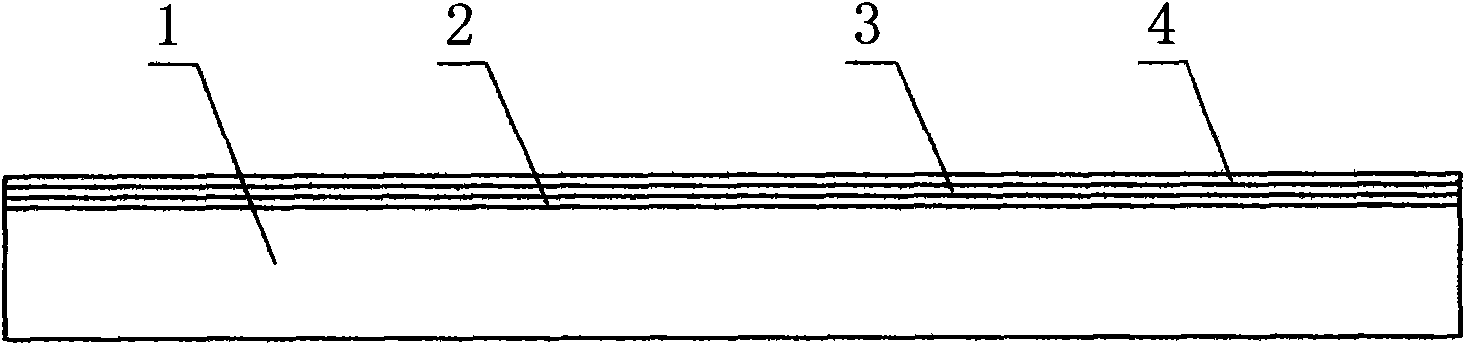

[0040] A cross-sectional view of a UV-cured adhesive film glass figure 1 As shown, among them: 1 is glass, 2 is the bottom UV curing glue, 3 is the middle UV curing glue, and 2 is the surface UV curing glue. When manufacturing UV-curable single-sided adhesive film glass, first, use a roll coater to evenly coat the bottom layer of UV-curable adhesive 2 on the surface of glass 1, heat with infrared rays to volatilize the solvent, and heat with infrared rays to volatilize the solvent. After irradiation, the bottom layer of UV-curable glue is solidified on the surface of glass 1 to form the bottom layer of UV-curable film 2, and the middle-layer UV-curable glue 3 is evenly coated on the surface of the bottom layer of UV-curable glue 2 with a roller coater, and heated by infrared rays to make The solvent is volatilized, and after being irradiated by ultraviolet light, the middle layer of UV curing glue is cured on the surface of the bottom layer of UV curing glue 2 to form a UV fil...

Embodiment 2

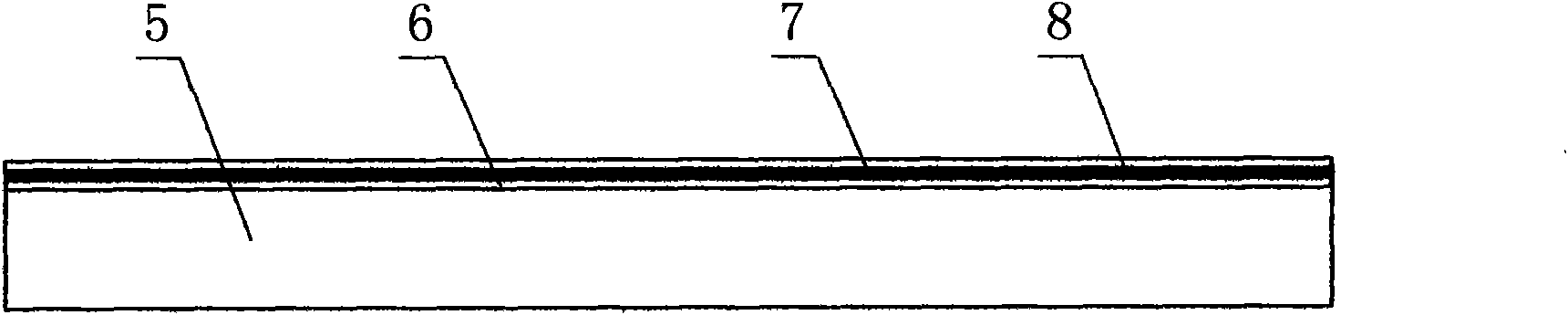

[0042] A cross-sectional view of a UV-curable adhesive film glass containing nano-indium tin oxide figure 2 As shown, wherein: 5 is glass, 6 is the bottom UV curing adhesive, 7 is the nano-indium tin oxide UV curing adhesive, and 8 is the surface UV curing adhesive. When manufacturing UV-curable adhesive film glass containing nano-indium tin oxide, first, use a roll coater to evenly coat the bottom UV-curable adhesive 6 on the surface of the glass 5, heat with infrared rays to volatilize the solvent, and after irradiation with ultraviolet light, The bottom layer of UV-curable glue is solidified on the surface of the glass 5 to form the bottom layer of UV-curable film 6, and the middle-layer nano-indium tin oxide UV-curable glue is evenly coated on the surface of the bottom layer of UV-curable glue 6 with a roll coater, and heated by infrared rays The solvent is volatilized, and after being irradiated by ultraviolet light, the middle-layer nano-indium tin oxide UV-curable glue...

Embodiment 3

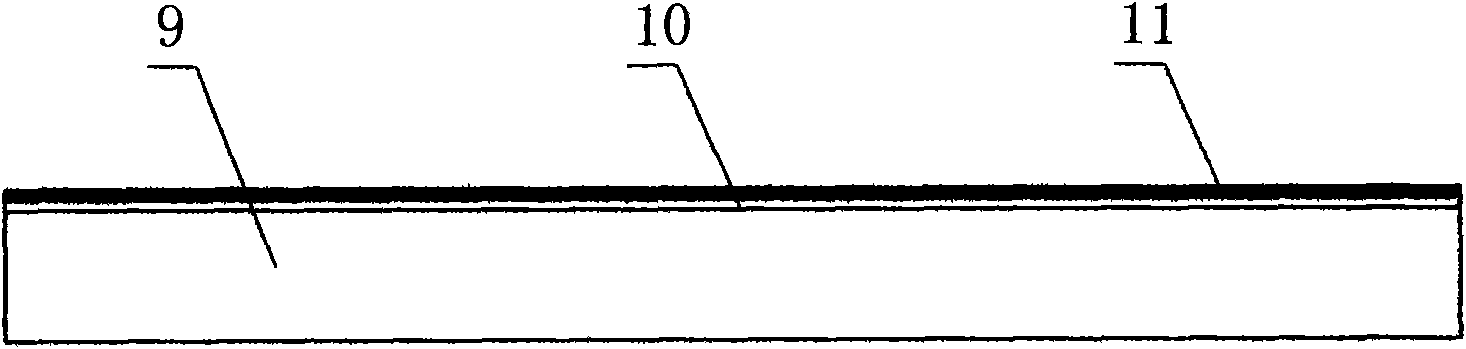

[0044] A cross-sectional view of a UV-cured sterilizable film glass containing nano-silver image 3 As shown, wherein: 9 is glass, 10 is the bottom UV-curable adhesive, and 11 is nano-silver UV-curable adhesive. When manufacturing UV-curable sterilizing film glass, first, use a roll coater to evenly coat the bottom UV-curable adhesive 10 on the surface of the glass 9, heat with infrared rays to volatilize the solvent, and irradiate the bottom layer with UV light. The cured glue 10 is cured on the surface of the glass 9, and the glass 9 with the bottom UV-cured glue layer 10 is sent to the roller coater again, and the roller coater evenly coats the surface layer of nano-silver UV-cured glue 11 To the surface of the bottom UV-curable adhesive layer 10, heat with infrared rays to volatilize the solvent, and after ultraviolet light irradiation, the surface layer nano-silver UV-curable adhesive 11 is cured on the surface of the bottom UV-curable adhesive film 10, and the surface la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com