Rotational flow absorption filter concentration and separation technique and device thereof

A technology of adsorption filtration and process flow, which is applied in the direction of filtration separation, separation method, filtration circuit, etc. It can solve the problems of high chemical consumption in subsequent treatment, large area occupied by gravity concentration, poor concentration effect, etc., and achieve sludge concentration ratio High, less space occupation, easy to clean and replace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

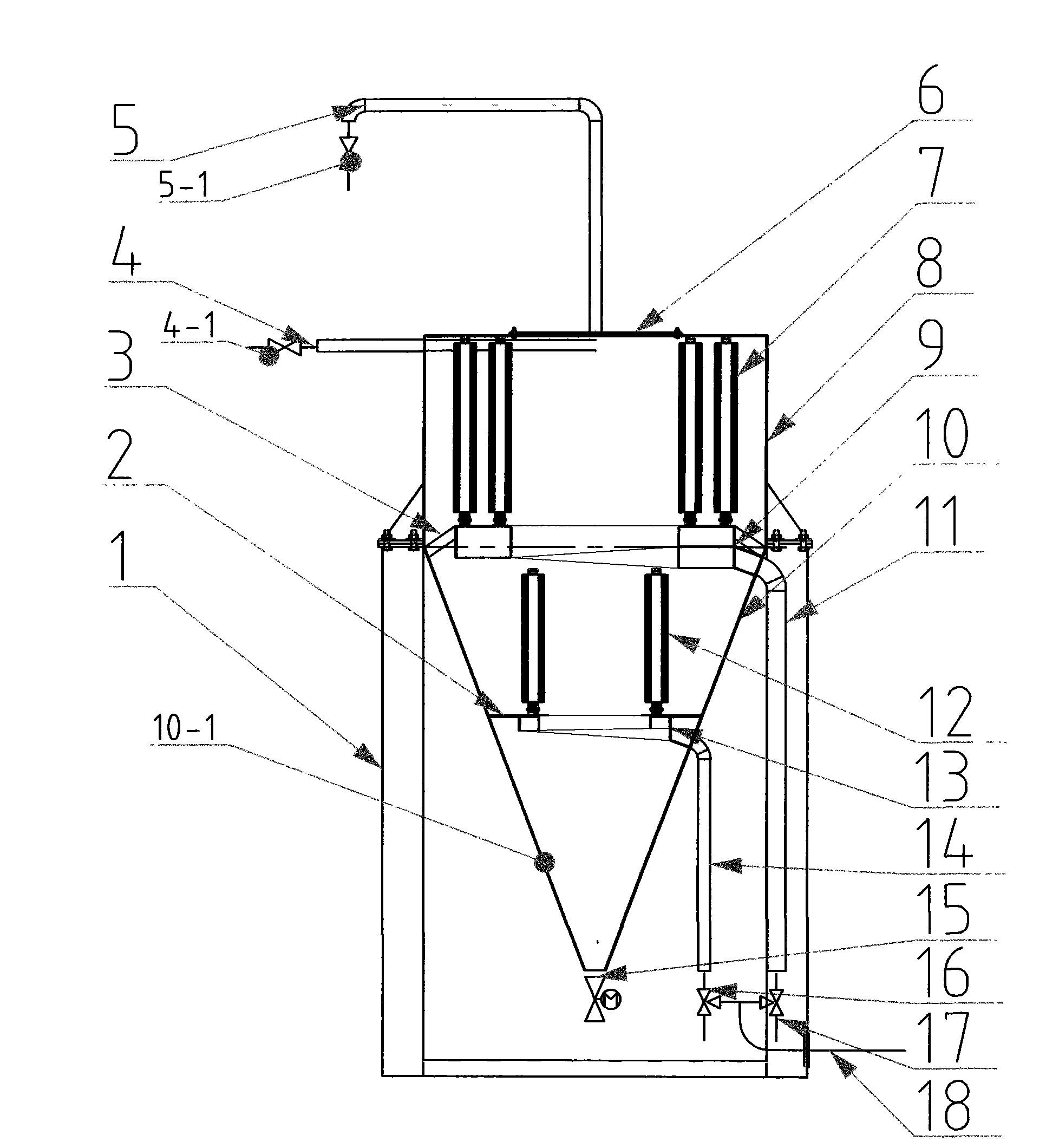

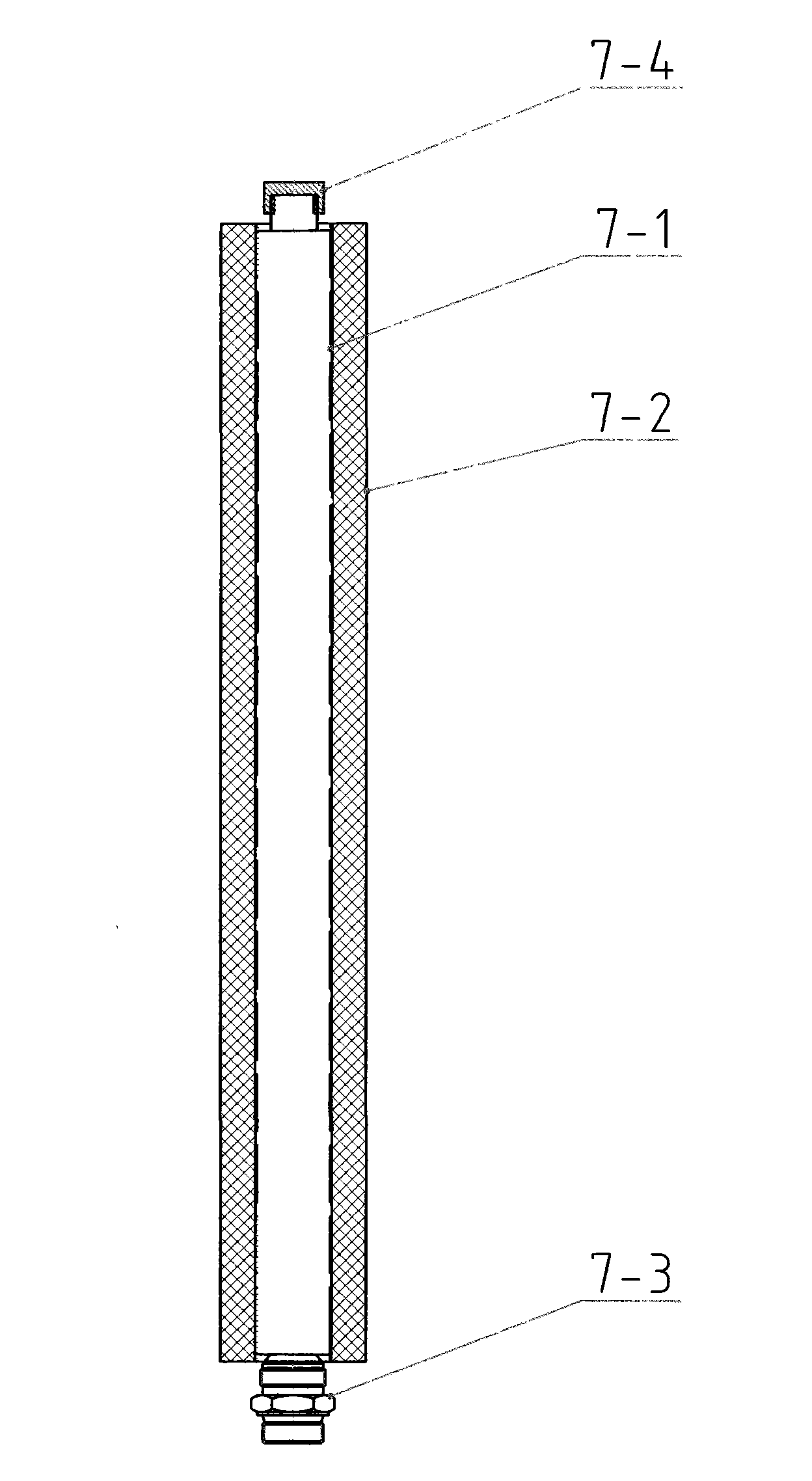

[0015] The bottom of the separator straight cylinder (8) is welded with a separator cone (10), which forms the tower body of the cyclone separator. The middle waist of the separator cone (10) is welded with a porous partition (2), and the lower part of the cone It is the mud collecting bucket (10-1), the tower body is installed on the bracket (1), the water inlet pipe (4) is installed in the tangential direction on the upper part of the tower body, and the water inlet water volume regulating valve (4- 1), the overflow pipe (5) is installed on the top of the tower body, the overflow valve (5-1) is installed on the overflow pipe (5), the inspection cover (6) is installed on the top of the tower body with connecting bolts, and the mud collecting bucket A mud discharge valve (15) is installed at the bottom of (10-1), and a number of adsorption, filtration and separation pipes (7) are arranged in a ring and vertically installed on the drainage collector (9), and the drainage is conn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com