Method and system for detecting consumption of photoresist and data classification and acquisition system

A detection method and detection system technology, which is applied in the program control of sequence/logic controller, photoplate-making process coating equipment, electrical program control, etc., can solve the problem of real-time detection of the actual consumption of raw materials and the inability to know the photoresist Problems such as actual consumption and inability to know the consumption value of raw materials to achieve the effects of reducing blindness, facilitating production management, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

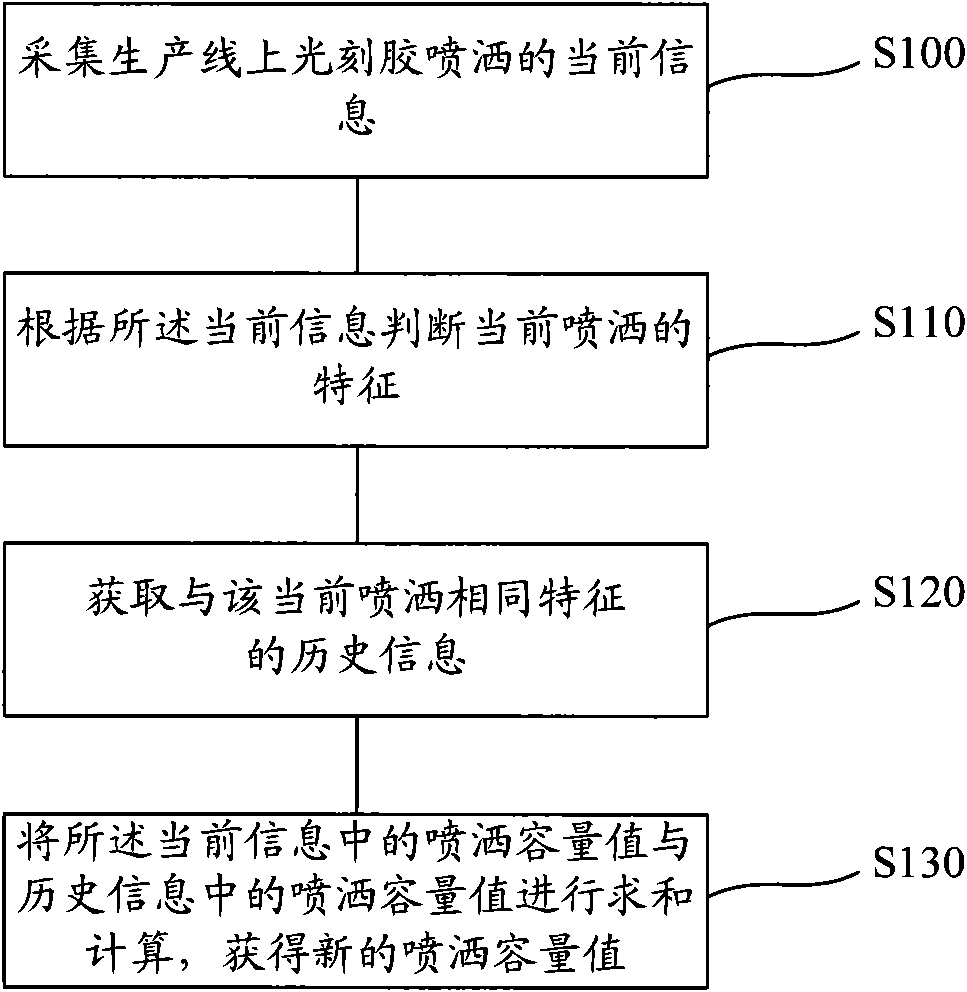

[0067] The invention provides a method for detecting the amount of photoresist. figure 2 It is a flowchart of an embodiment of the method for detecting the amount of photoresist used in the present invention.

[0068] Please refer to figure 2 , step S100 is to collect the current information of photoresist spraying on the production line; wherein the current information at least includes photoresist name, spraying capacity value and spraying time.

[0069] Step S110 is to judge the characteristics of the current spraying according to the current information.

[0070] Step S120 is to acquire the historical information of the photoresist with the same characteristics as the current spraying.

[0071] Step S130 is to calculate the sum of the spraying capacity value in the current information and the spraying capacity value in the histori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com