Method for preparing polyphase structure drill rod materials

A drill pipe and consistent technology, applied in the field of preparation of multiphase structure drill pipe materials, can solve problems such as failure accidents and large cracks, and achieve the effect of improving the fatigue limit

Active Publication Date: 2009-11-04

BC P INC CHINA NAT PETROLEUM CORP +1

View PDF0 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

When the external energy input is enough, these short cracks will continue to grow and aggregate, and finally form large cracks, which become the source of fatigue cracks, and then expand, causing failure accidents

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-3

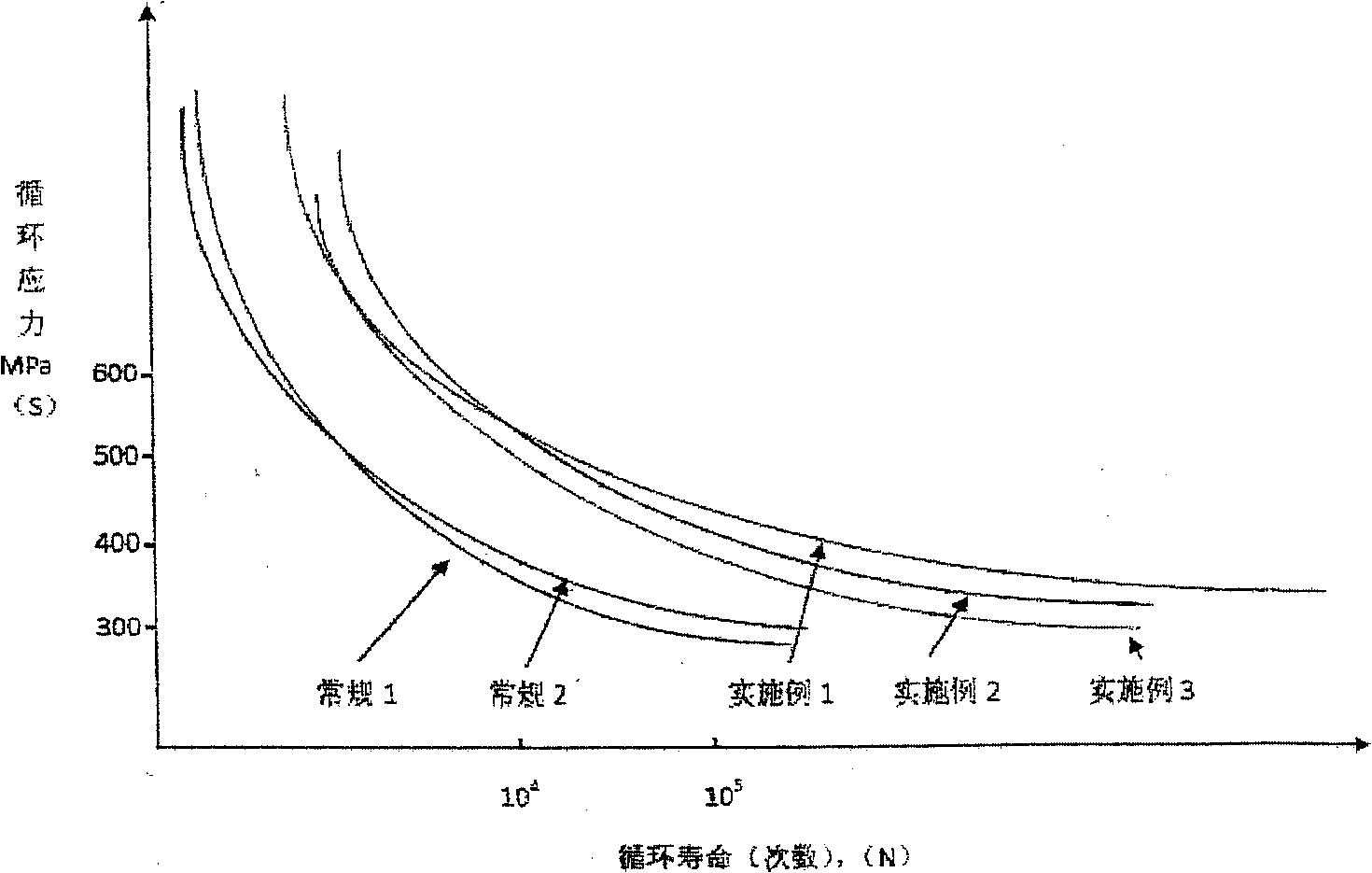

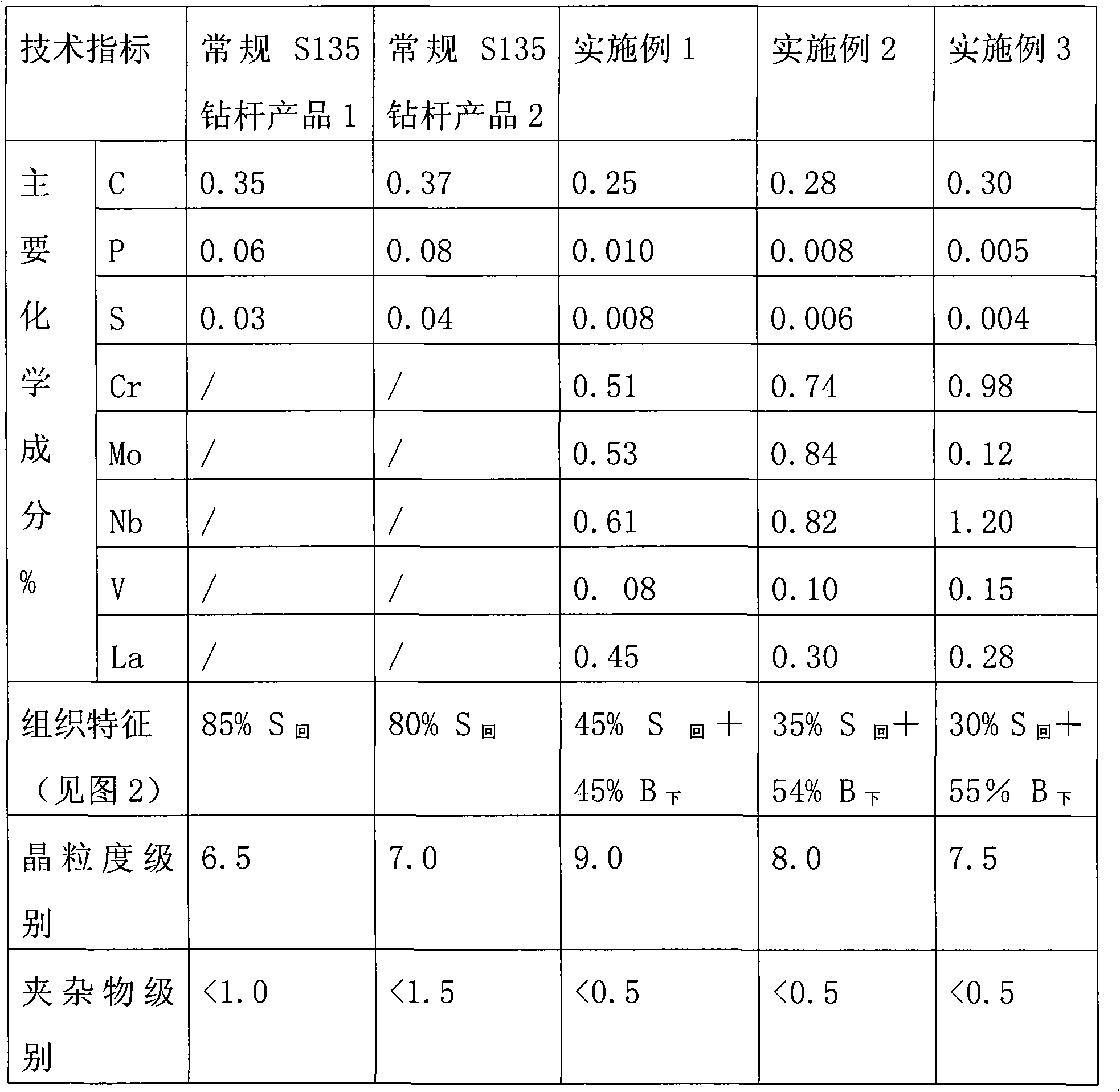

[0018] The performance of the petroleum drill pipe prepared by using the material of the present invention is compared with two typical S135 drill pipes on the domestic market. The effect of the embodiment is shown in Table 1:

[0019] Table 1 Example effect data comparison

[0020]

[0021]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

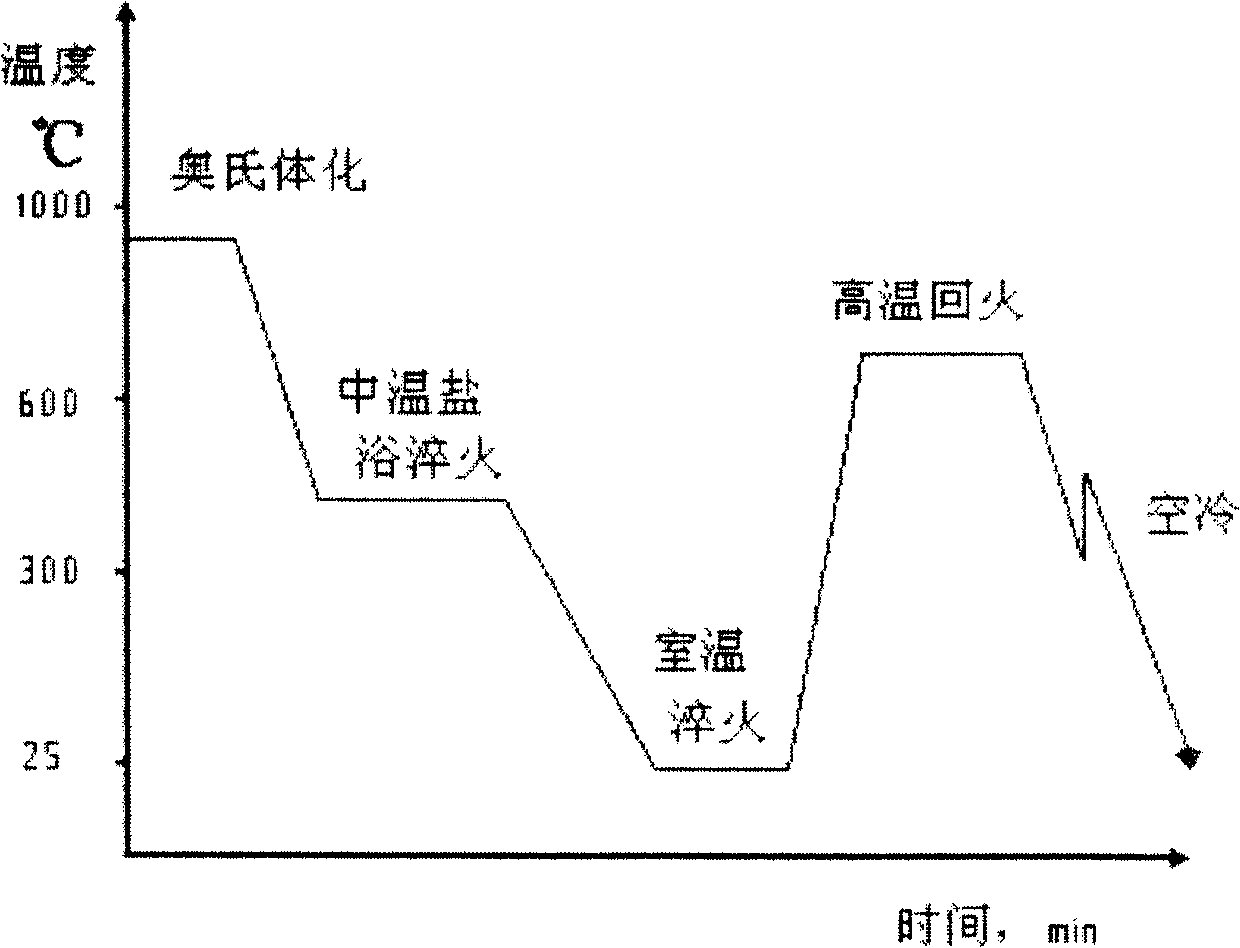

The invention relates to a method for preparing polyphase structure drill rod materials, which comprises the following compositions by mass percentage: 0.25 to 0.30 percent of carbon, less than 0.008 percent of sulfur, less than 0.010 percent of phosphorus, 0.5 to 1.0 percent of chromium, 0.6 to 1.2 percent of molybdenum, 0.10 to 0.15 percent of vanadium, 0.10 to 0.15 percent of niobium, 0.25 to 0.5 percent of lanthanum, and other elements and S135 steel grade drill rod elements. The heat treatment process comprises the following steps: firstly, performing vacuum melting and casting forming on various compositions, and treating the obtained product for 30 to 60 minutes at the temperature of between 925 and 935 DEG C after the obtained product is subjected to the production procedures of rolling and drilling of general drill rods; and secondly, cooling the obtained product to the temperature of between 280 and 420 DEG C, performing salt-bath quenching on the obtained product for 10 to 15 minutes, performing oil cooling on the obtained product to the room temperature, and performing tempering on the obtained product for 30 minutes at a temperature of between 560 and 620 DEG C. Compared with a common S135 drill rod, the fatigue life of the drill rod is improved by 3 to 4 times, and the fatigue limit of the drill rod is improved by 40 to 50 percent.

Description

Technical field [0001] The invention relates to a method for preparing a drill pipe material with a complex structure composed of lower bainite, tempered sorbite and a small amount of retained austenite with high fatigue resistance. Background technique [0002] With the development of the world petroleum industry, oil and gas wells are getting deeper and deeper. There are wells more than 8,000 meters deep. The increase in well depth makes drilling conditions more and more complicated. Therefore, during the drilling process, the working conditions encountered by the drill pipe and the forces on the drill pipe are becoming more and more complex, such as tension, compression, bending, torsion, shearing and their combination, alternating loads, etc., which have significantly increased Probability of drill pipe failure. The failure of the drill pipe sometimes leads to the scrapping of the entire well, resulting in significant economic losses, and even casualties. With the development...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/26C21D9/00C21D1/18

CPCY02P10/20

Inventor 张亚平韩礼红齐承竺徐欣冯耀荣林凯上官丰收

Owner BC P INC CHINA NAT PETROLEUM CORP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com