Method for manufacturing intelligent composite-material laminates used for monitoring structural longitudinal strain

A technology of composite material layer and manufacturing method, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems affecting the measurement accuracy of grating strain, the process cannot be guaranteed, and the optical fiber is easy to damage, so as to improve the accuracy of strain monitoring and avoid chirp Chirp phenomenon, the effect of meeting sensitivity requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

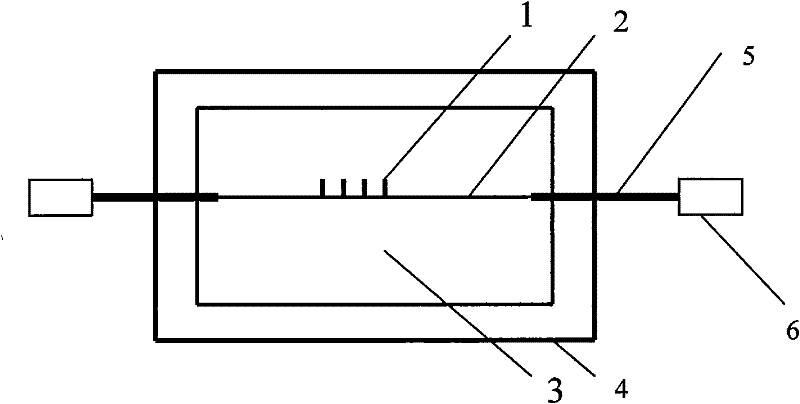

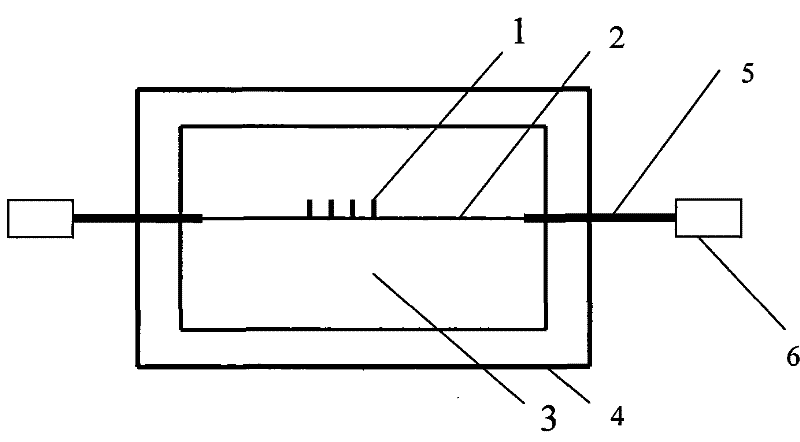

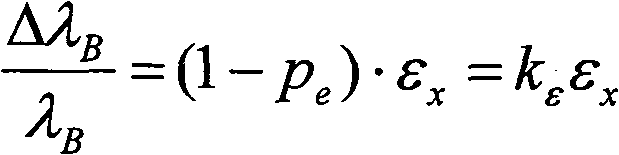

[0016] see figure 1 , a method for manufacturing an intelligent composite laminate for structural longitudinal strain monitoring, the steps are as follows:

[0017] (1) Choose a CFRP with a thickness of 0.2mm or a GFRP composite prepreg with a thickness of 0.15mm. CFRP is laminated according to the warp / weft direction of 50 / 50 (mass ratio); GFRP is laid according to the warp / weft direction of 80 / 20 (mass ratio) ) of the lay-up structure lay-up;

[0018] (2) The composite material prepreg is cut according to 100mm×20mm, and the layers are laid by hand;

[0019] (3) Apply prestress at both ends of the fiber grating, put it into the composite material laminate along the direction of 100mm, and insert the port part into the composite material with a quartz protective sleeve;

[0020] (4) Seal the composite material layer with a vacuum bag, and the fiber grating passes through the vacuum bag through the silicone rubber sealing strip;

[0021] (5) Put the composite layer structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com