Preparation method and device for industrial microwave heating diffusion coating

A microwave heating and diffusion coating technology, which is applied in the direction of solid-state diffusion coating, coating, metal material coating technology, etc., can solve the problems that industrial production and processing cannot be applied, continuous close contact cannot be guaranteed, and ceramic containers are difficult to manufacture. , to achieve the effect of promoting thermal diffusion metallurgical chemical reaction, accelerating thermal diffusion process, and shortening heat treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

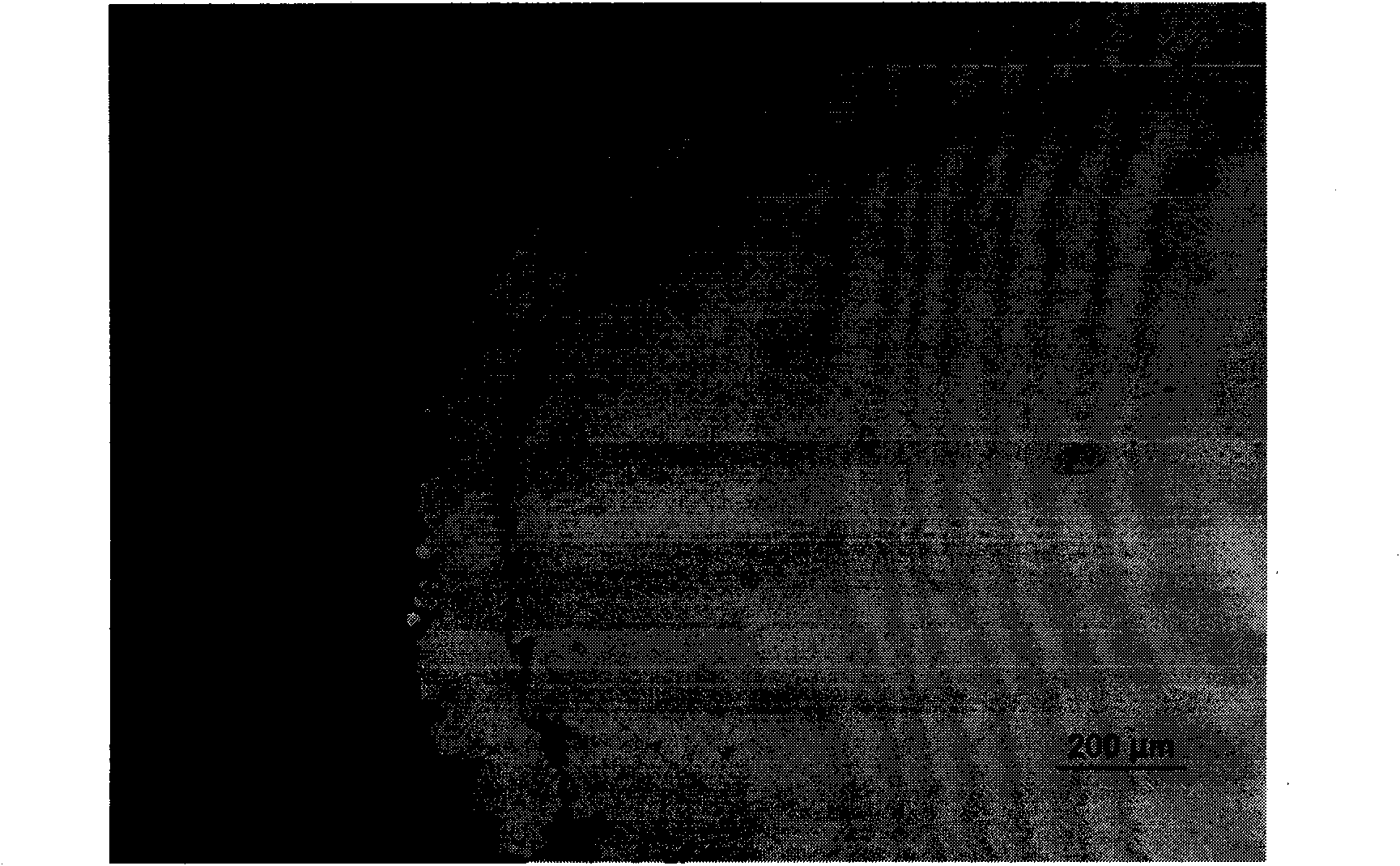

[0038] Embodiment 1: After a small amount of 25# carbon steel metal gaskets processed before pickling are embedded in 325 mesh 60%wt zinc powder, 200 mesh 37%wt alumina powder and 3%wt ammonium chloride powder are mixed uniformly Infiltration agent, filled into a rolling sealed metal container, wrapped in quartz sand and placed in an insulating ceramic container to seal the cover, the volume of quartz sand is approximately 60% of the volume of the metal container, and then placed in a microwave oven at 0.5 Rolling and heating at rpm for 25 minutes, and then keeping it warm for 60 minutes, a zinc-iron alloy infiltrated layer with a thickness of 110-130 microns can be obtained on the surface of the metal gasket. image 3 and Figure 4 It is the metallographic photo of the zinc-iron alloy infiltrated layer obtained on the surface of the metal gasket.

Embodiment 2

[0039] Example 2: Embed high-strength bolts pretreated by pickling in 325 mesh 40%wt zinc powder, 10%wt aluminum powder, 300 mesh 48%wt alumina powder and 2%wt ammonium chloride powder Put it into the rolling metal container and embed it in the quartz sand. The volume of the quartz sand is approximately 70% of the volume of the metal container. Then place it in a microwave oven and heat it for 30 minutes under the rolling state of 1.5rpm. Control the temperature at 400°C. Then hold the temperature for 40 minutes, and finally cool in the air, and obtain a zinc-aluminum-iron composite coating with an average thickness of about 50-60 microns on the surface of the high-strength bolt.

Embodiment 3

[0040] Embodiment 3: Embed a small amount of 25# carbon steel gaskets treated before pickling in 300 mesh 30%wt zinc powder, 200 mesh 60%wt alumina powder and 3%wt ammonium chloride, 7%wt Put metal titanium oxide powder into the infiltration agent after uniform mixing, and put it into a rolling sealed metal container wrapped with microwave heating material mixed with quartz sand and silicon carbide (ratio 10:1). The volume of the mixed microwave heating material powder is approximately 80 % of the volume of the metal container, then placed in a microwave oven at 3.0rpm and heated for 40 minutes in a rolling state to control the temperature at 380 ° C, keep the temperature for 50 minutes and then cool in the air, the surface of the gasket can be obtained with an average thickness of 40-50 microns Zinc-iron alloy coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com