High-strength hot rolling automotive frame steel plate and manufacturing method thereof

A technology for automobile girders and manufacturing methods, which is applied in the field of steel materials and hot-rolled steel products, can solve problems affecting the cold forming performance of steel, and achieve the effects of high fatigue strength, lightening the weight of automobiles, and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

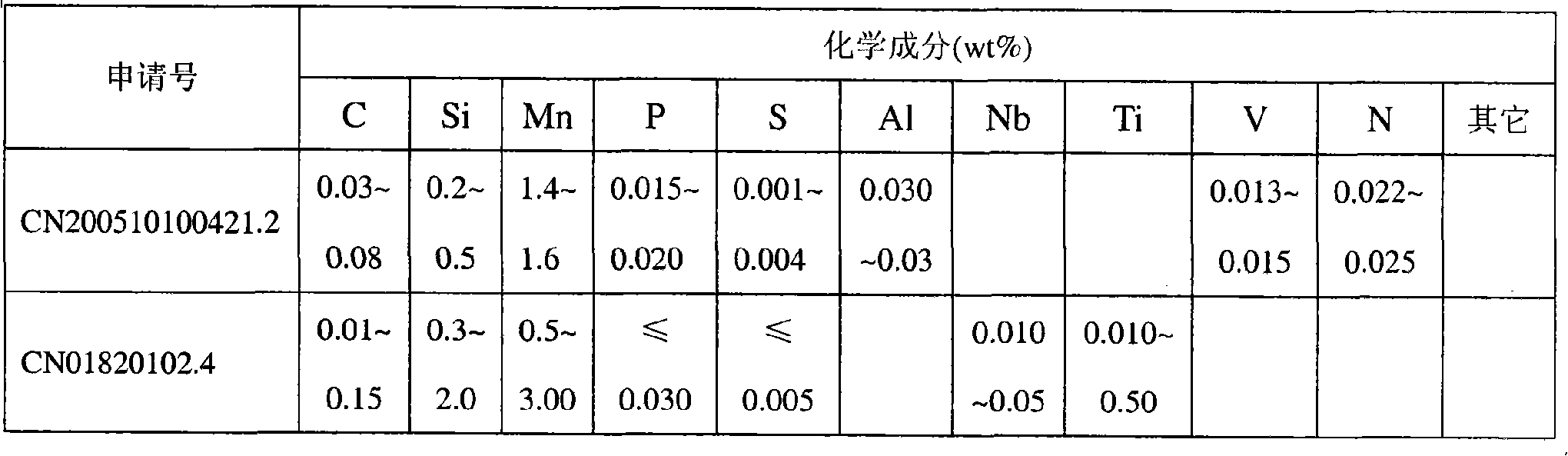

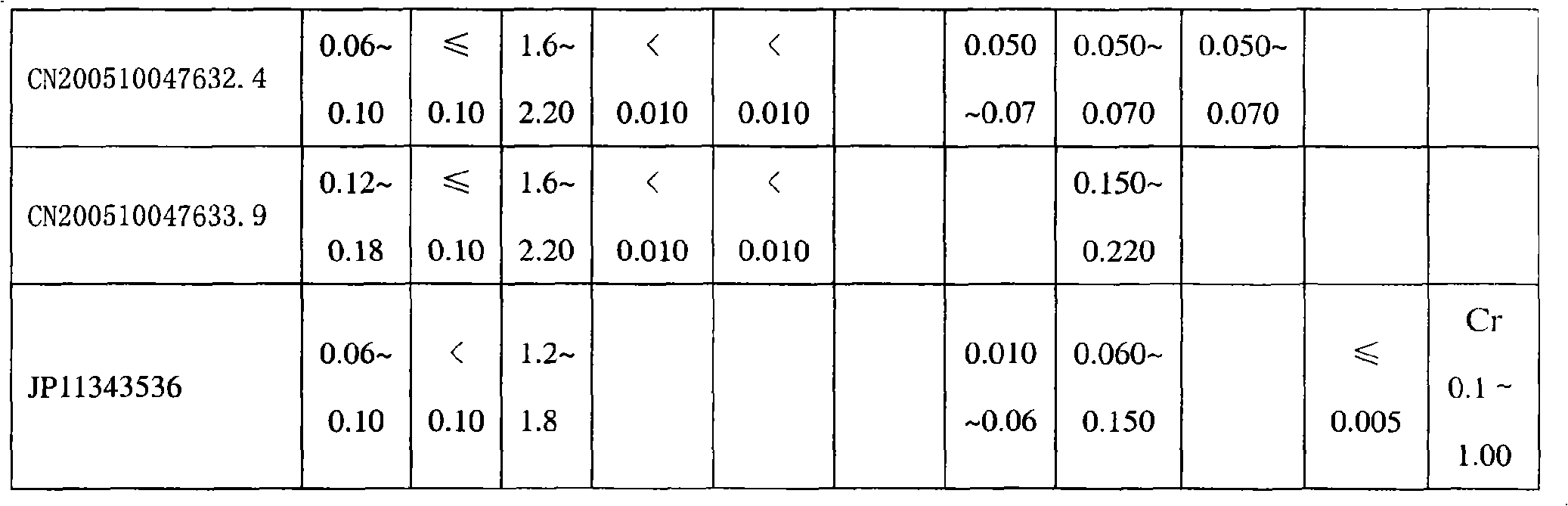

Method used

Image

Examples

Embodiment 1

[0037] The chemical composition of the high-strength hot-rolled automobile frame steel plate of the present invention comprises:

[0038] C: 0.07wt%, Si: 0.03wt%, Mn: 1.16wt%, P: 0.01wt%, S: 0.003wt%, Al: 0.047wt%, N: 0.0025wt%, Nb: 0.015wt%, Ti: 0.070wt%, Ca: 0.0021wt%, the balance being Fe and unavoidable impurities.

[0039] Sample 1: Molten steel is smelted according to the above chemical composition, cast into a billet, heated at 1250°C, and then rolled in the austenite zone, the rolling deformation is greater than 80%, the final rolling temperature is 850°C, and the steel plate after final rolling Cool to 565°C at a cooling rate of 50°C / s for coiling, then air-cool to room temperature after coiling, and the thickness of the steel plate is 8mm.

[0040]Sample 2: Molten steel is smelted according to the above chemical composition, cast into a billet, heated at 1220°C, and rolled in the austenite zone, the rolling deformation is greater than 80%, the final rolling temperat...

Embodiment 2

[0043] The chemical composition of the high-strength hot-rolled automobile frame steel plate of the present invention comprises:

[0044] C: 0.07wt%, Si: 0.05wt%, Mn: 1.45wt%, P: 0.01wt%, S: 0.002wt%, Al: 0.040wt%, N: 0.0048wt%, Nb: 0.046wt%, Ti: 0.10wt%, Ca: 0.0045wt%, the balance being Fe and unavoidable impurities.

[0045] Sample 1: Molten steel is smelted according to the above chemical composition, cast into a billet, heated at 1250°C, and then rolled in the austenite zone, the rolling deformation is greater than 80%, the final rolling temperature is 850°C, and the steel plate after final rolling Cool to 585°C at a cooling rate of 46°C / s for coiling, then air-cool to room temperature after coiling, and the thickness of the steel plate is 8mm.

[0046] Sample 2: Molten steel is smelted according to the above chemical composition, cast into a billet, heated at 1230°C, and then rolled in the austenite zone, the rolling deformation is greater than 80%, the final rolling tem...

Embodiment 3

[0048] The chemical composition of the high-strength hot-rolled automobile frame steel plate of the present invention comprises:

[0049] C: 0.06wt%, Si: 0.06wt%, Mn: 1.85wt%, P: 0.01wt%, S: 0.002wt%, Al: 0.043wt%, N: 0.0038wt%, Nb: 0.050wt%, Ti: 0.15wt%, Ca: 0.002wt%, the balance is Fe and unavoidable impurities.

[0050] Sample 1: Molten steel is smelted according to the above chemical composition, cast into a billet, heated at 1250°C, and then rolled in the austenite zone, the rolling deformation is greater than 80%, the final rolling temperature is 850°C, and the steel plate after final rolling Cool to 530°C at a cooling rate of 42°C / s for coiling, then air-cool to room temperature after coiling, and the thickness of the steel plate is 8mm.

[0051] Sample 2: Molten steel is smelted according to the above chemical composition, cast into a billet, heated at 1230°C, and then rolled in the austenite zone, the rolling deformation is greater than 80%, the final rolling tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com