Orange-red long afterglow Luminescent Material

A long afterglow luminescence, orange-red technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of waste gas human body and environmental hazards, complex production process, difficult to meet needs and other problems, achieve non-radioactive, simple preparation method, reduce effect of miscellaneous

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

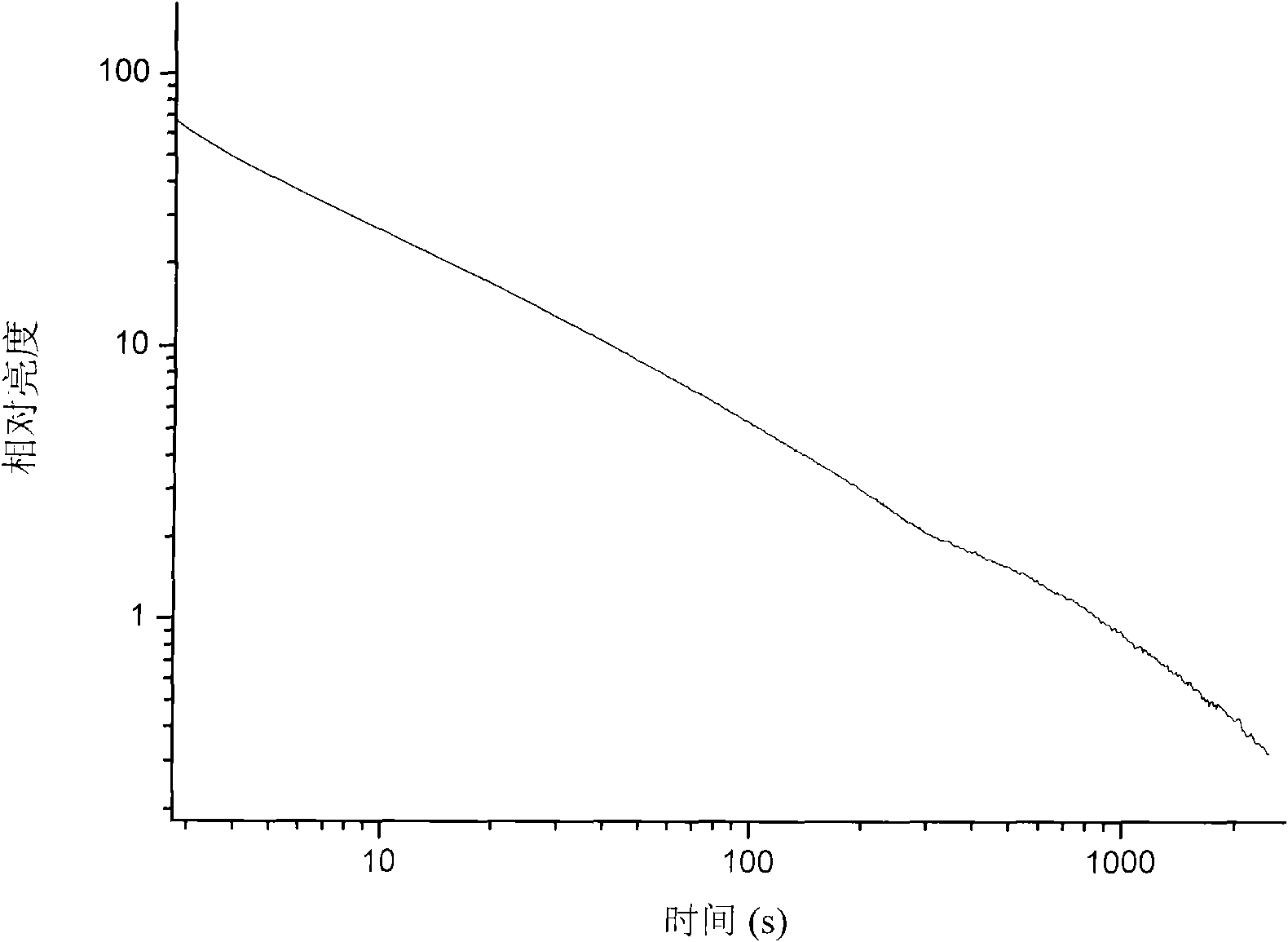

[0041] According to the chemical formula Ca 2 SnO 4 :Sm 0.01 , accurately weigh the oxide or carbonate of the corresponding element and 2-3% H 3 BO 3 , pour the above raw materials into an agate mortar, then add absolute ethanol or acetone as a dispersant according to 3~6ml / (gram raw material), after fully grinding and mixing, transfer to a corundum crucible, in an air atmosphere, at 1100 ~ Sinter at 1300°C for 3-6 hours, cool to room temperature, take out the sample and grind it again, keep it at 800-1200°C for 1-4h, cool to room temperature, take out the sample and grind to obtain the example material. The material is white in appearance, and XRD test shows that the main phase is Ca 2 SnO 4 . The excitation spectrum of this material is composed of a series of peaks in the range of 320-575nm, the strongest peak is located at 408nm, and other peaks are located at 348, 364, 378, 478 and 560nm. figure 1 . The emission spectrum of this material has 3 strong peaks, the str...

Embodiment 2

[0043] According to the chemical formula Ca 2 SnO 4 :Sm 0.01 , accurately weigh the oxide or carbonate of the corresponding element and the weight of the raw material 0.5-3% H 3 BO 3 and 0.5-3% NH 4 Cl, pour the above materials into an agate mortar, then add absolute ethanol or acetone as a dispersant at 3 to 6ml / (gram of raw material), fully grind and mix, then transfer to a corundum crucible, and in an air atmosphere, at 1100 ~ Sinter at 1300°C for 3-6 hours, cool to room temperature, take out the sample and grind it again, keep it at 800-1200°C for 1-4h, cool to room temperature, take out the sample and grind to obtain the example material. attached Figure 4 The XRD patterns of the products prepared under different conditions are given. The material is white in appearance, and XRD test shows that the main phase is Ca 2 SnO 4 , see attached Figure 4-4 . The excitation spectrum of this material is composed of a series of peaks in the range of 320-575nm, the strong...

Embodiment 3

[0045] According to the chemical formula Ca 2 SnO 4 :Sm 0.01 , accurately weigh the oxide or carbonate of the corresponding element and the raw material weight 1~3%H 3 BO 3 and 0.5-3% NH 4 Cl, pour the above materials into an agate mortar, then add absolute ethanol or acetone as a dispersant at 3 to 6ml / (gram of raw material), fully grind and mix, then transfer to a corundum crucible, and in an air atmosphere, at 1100 ~ Sinter at 1300°C for 3-6 hours, cool to room temperature, take out the sample and grind it again, keep it at 800-1200°C for 1-4h, cool to room temperature, take out the sample and grind to obtain the example material. The material is white in appearance, and XRD test shows that the main phase is Ca 2 SnO 4 . The excitation spectrum of this material consists of a series of peaks in the range 320-575nm, with the strongest peak at 408nm and other peaks at 348, 364, 378, 478 and 560nm, see attached Figure 8 . The emission spectrum of this material has 3 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com