Mg doped zinc oxide luminescent nanoparticle and the preparation method thereof

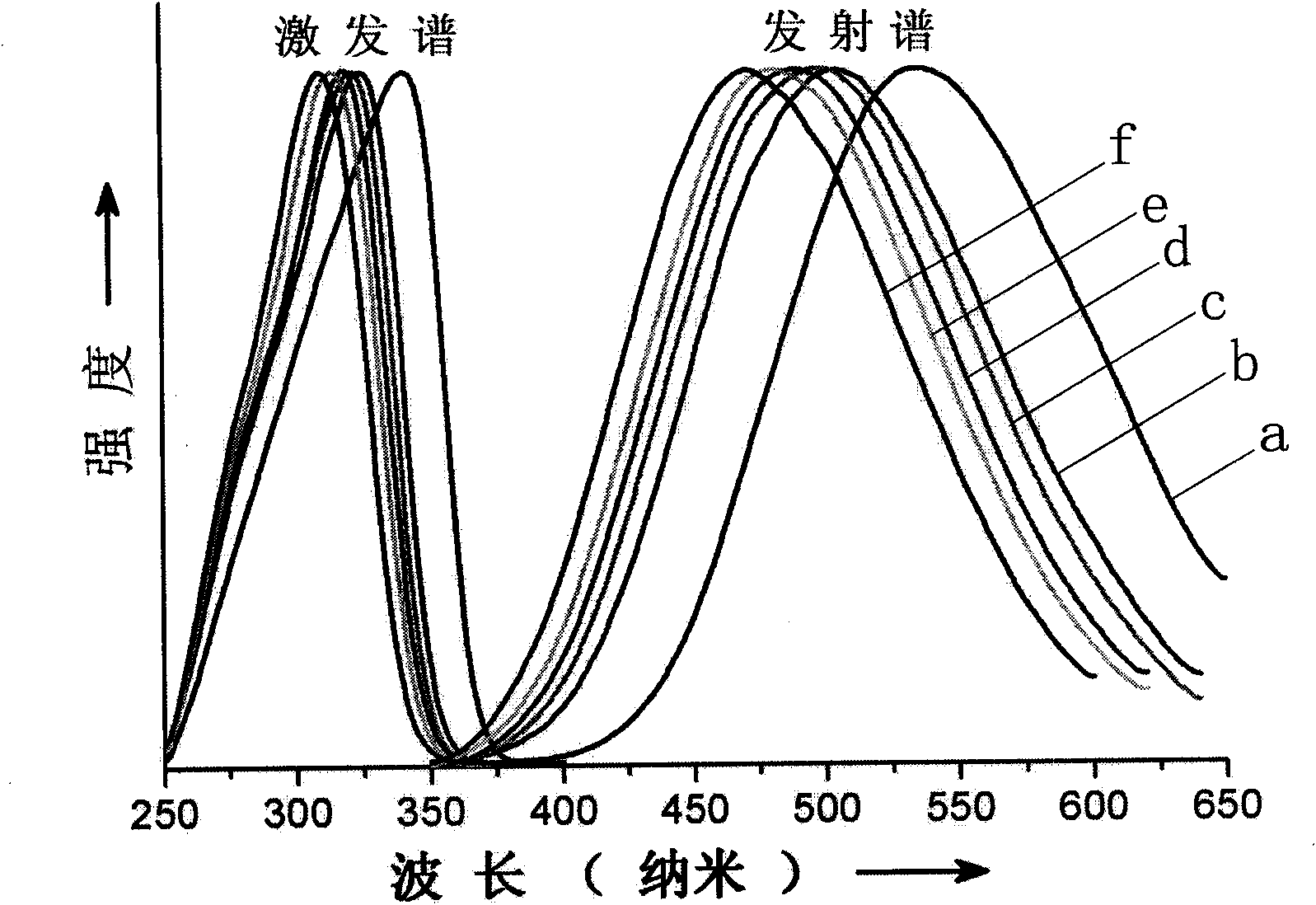

A nanoparticle and zinc oxide technology, which is applied in the field of nanomaterials, can solve the problems that the product only has ultraviolet fluorescence, and the ultraviolet emission peak shifts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

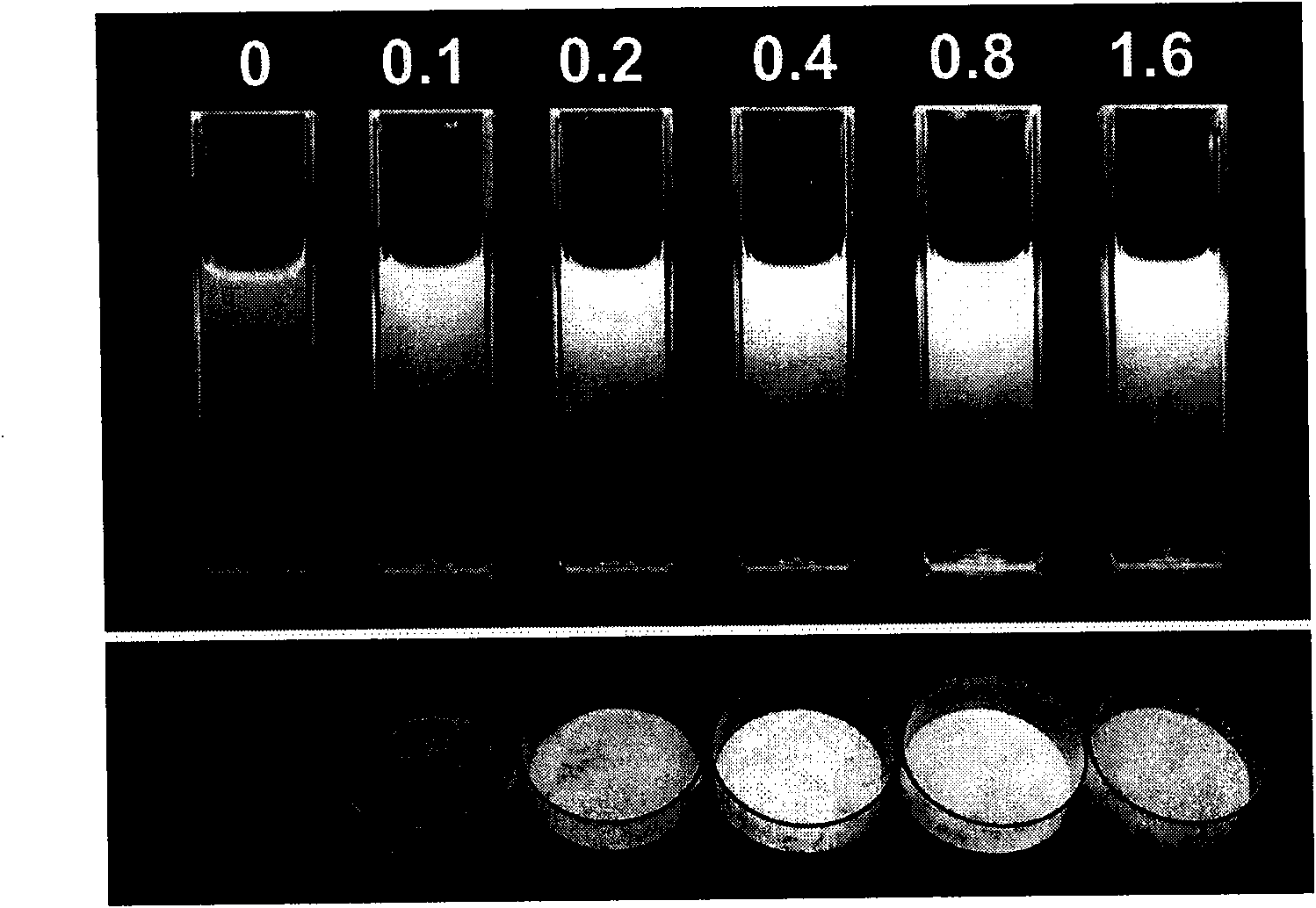

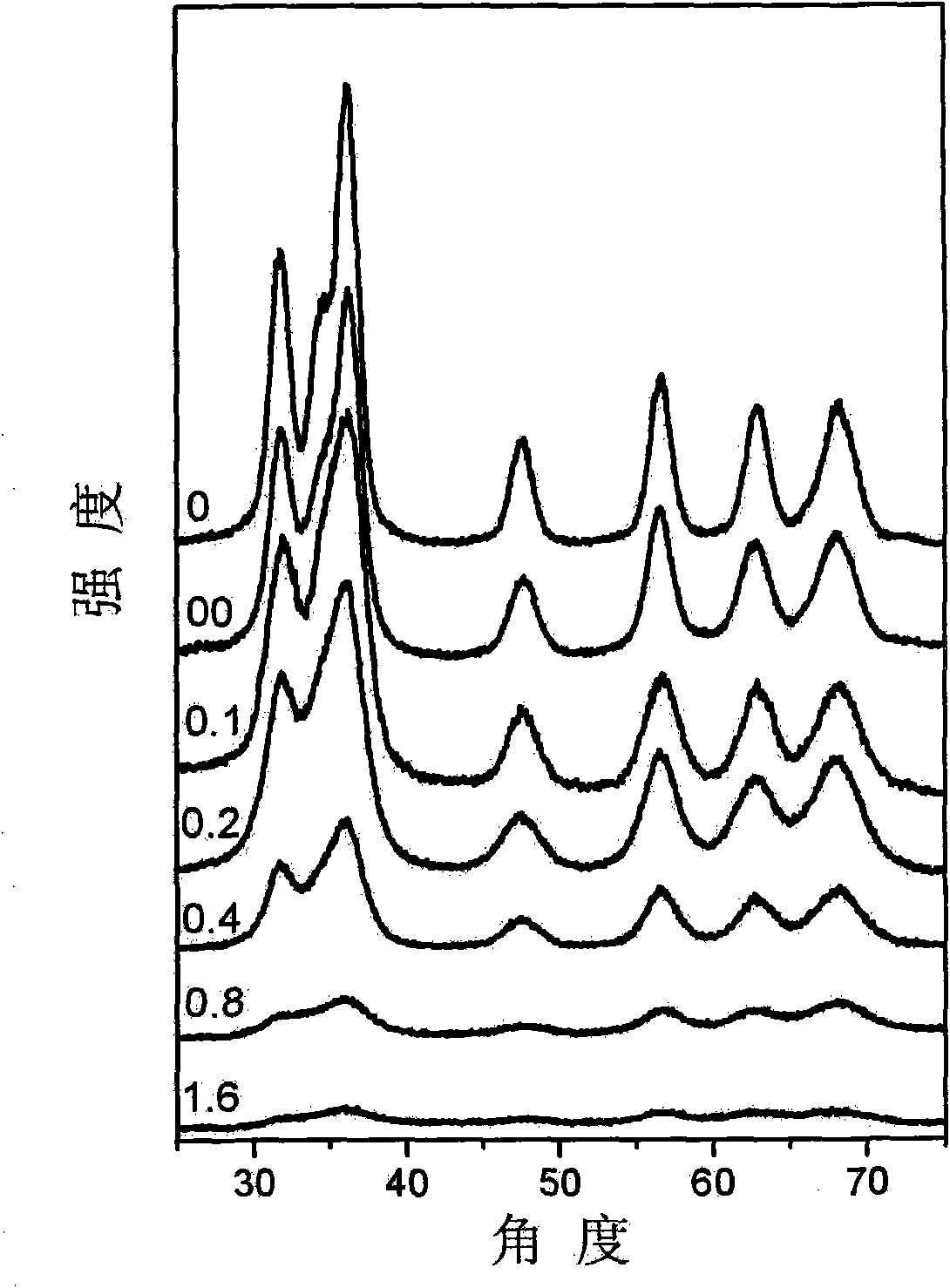

Embodiment 1

[0016] 0.002mol zinc acetate ZnAc 2 2H 2 O and 0.003mol lithium hydroxide LiOH·H 2 O powder was added to 40 ml of tetraethylene glycol TEG, and after stirring at room temperature for several hours, a clear luminescent solution was obtained, in which the zinc salt concentration was 0.05 mol / L. Then, add magnesium acetate MgAc 2 4H 2 O powder, stirring and dissolving, where the molar ratio Mg / Zn=0. Insert an ultrasonic probe of metal titanium into the solution, at an intensity of 1000W / cm 2 , working continuously for 2 minutes at a frequency of 20kHz, at this time the solution temperature has risen to about 180°C. Immediately after, the solution was rapidly cooled in an ice-water bath, and finally stored at room temperature. Add 150mL of ethyl acetate to the solution to precipitate ZnO. After centrifugation, it can be dissolved in non-aqueous solvents such as ethanol, and then perform various spectral measurements and transmission electron microscope analysis. The quantum ...

Embodiment 2

[0018] The preparation method and testing process are the same as in Example 1, but the molar ratio Mg / Zn=0.1.

Embodiment 3

[0020] The preparation method and testing process are the same as in Example 1, but the molar ratio Mg / Zn=0.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com