Gemini ampholytic surfactant with flexible linking group and preparation method thereof

A surfactant, flexible connection technology, applied in chemical instruments and methods, dissolution, chemical/physical processes, etc., can solve the requirements of high synthesis conditions, few reports of amphoteric gemini surfactants, and large scale gemini surfactants. Expensive raw materials are used to achieve the best surface properties, a wide range of pH values, and increased stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

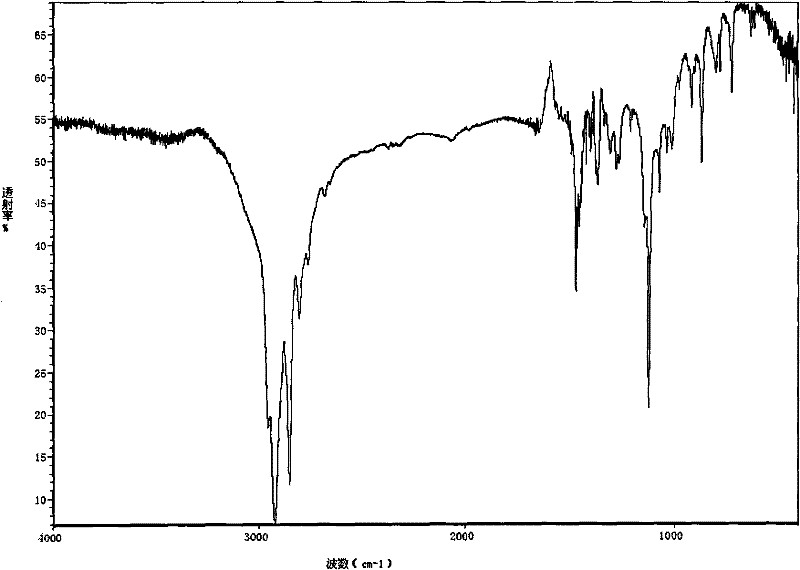

[0043] Weigh 50g (0.27mol) of dodecylamine, 19.32g (0.13mol) of dichloroethyl ether, and 1.6g (0.005mol) of tetrabutylammonium bromide and dissolve them in 100mL of toluene to make a solution. 1. In the 500ml four-necked flask of the condensing device, heat up to 75°C, dissolve 10.80g (0.27mol) of NaOH in 100ml of water to make a solution, add dropwise through the dropping funnel for about 0.5h, and continue to reflux and stir for 5h after the addition is complete. After the reaction was completed, layers were separated in a separatory funnel, the aqueous layer was extracted with toluene and combined into the organic phase, the organic phase was washed with water until neutral and dried with anhydrous calcium chloride, and the solvent was distilled off under reduced pressure to obtain a light yellow solid product N, N'--20 Dialkyl-3-oxa-1,5-pentanediamine. Its infrared spectrum is as figure 1 shown.

[0044] Weigh 18.9g (0.2mol) of chloroacetic acid and 16g (0.4mol) of NaOH ...

Embodiment 2

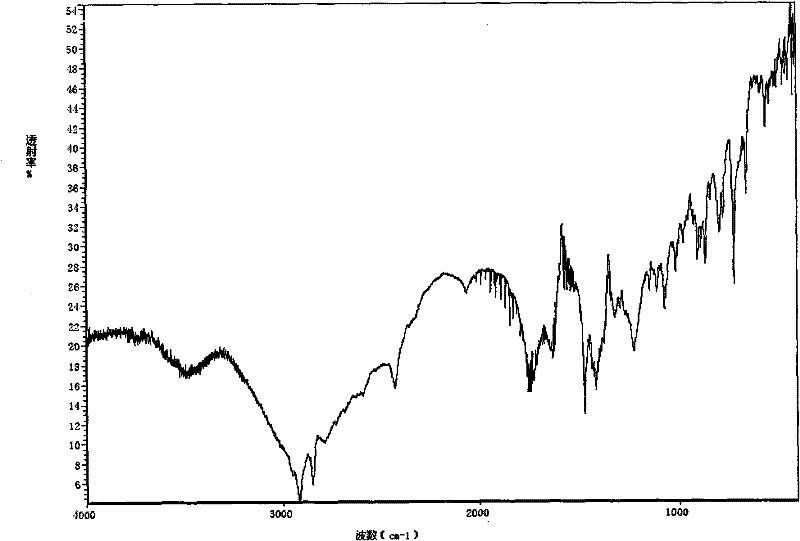

[0047]Weigh 100g (0.54mol) of dodecylamine, 30.89g (0.13mol) of dibromoethyl ether, and 1.82g (0.005mol) of cetyltrimethylammonium bromide and dissolve them in 100mL of absolute ethanol to make a solution, add Put it into a 500ml four-necked flask equipped with mechanical stirring, a thermometer, and a condensing device, raise the temperature to 70°C, dissolve 10.80g (0.27mol) of NaOH in 100ml of water to make a solution, add dropwise to the dropping funnel for about 0.5h, add dropwise Continue to reflux and stir the reaction for 5h, after the reaction is completed, separate layers in the separatory funnel, extract the water layer with toluene and merge it into the organic phase, wash the organic phase with water until neutral and dry with anhydrous calcium chloride, remove the solvent by distillation under reduced pressure to obtain a light yellow solid product N,N'-behenyl-3-oxa-1,5-pentanediamine.

[0048] Weigh 21.7g (0.2mol) of 3-chloropropionic acid and 22.4g (0.4mol) of...

Embodiment 3

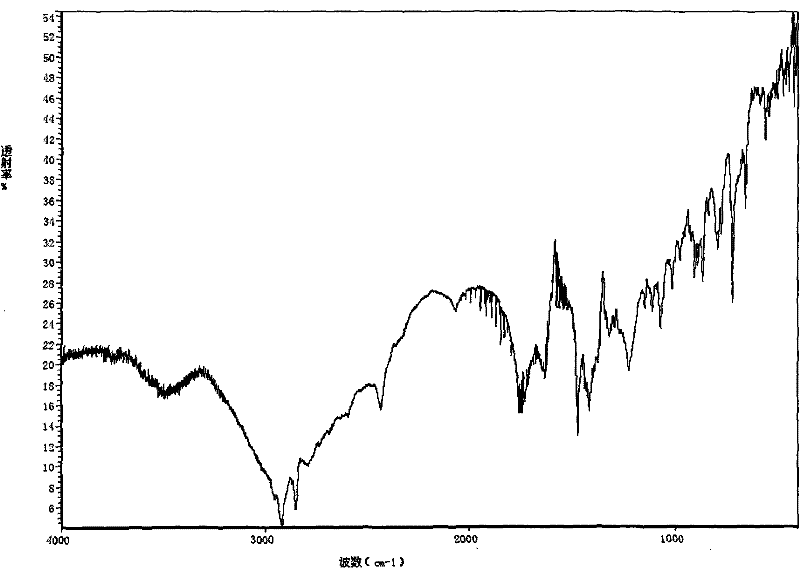

[0050] Weigh 145.26g (0.54mol) octadecylamine, 30.89g (0.13mol) dibromoethyl ether, cetyltrimethylammonium bromide 1.82g (0.005mol) and dissolve in 100mL cyclohexane to make a solution, add Put it into a 500ml four-necked flask equipped with mechanical stirring, a thermometer, and a condensing device, raise the temperature to 75°C, dissolve 10.80g (0.27mol) of NaOH in 100ml of water to make a solution, add it dropwise to the dropping funnel for about 0.5h, add dropwise Continue to reflux and stir the reaction for 4h. After the reaction is completed, separate layers in the separatory funnel, extract the water layer with toluene and merge it into the organic phase, wash the organic phase with water until it is neutral and dry with anhydrous calcium chloride, and distill off the solvent under reduced pressure to obtain a light yellow solid product N,N'-octadecyl-3-oxa-1,5-pentanediamine.

[0051] Weigh 27.8g (0.2mol) of bromoacetic acid and 16g (0.4mol) of NaOH and dissolve them ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com