Carbon nano-tube modified by in-situ polymerization based on plasma initiation and preparation method thereof

A technology of carbon nanotubes and plasma, which is applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of easy aggregation, high surface energy of carbon nanotubes, and restrictions on the application of carbon nanotubes, and achieve high efficiency , The method is simple and practical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

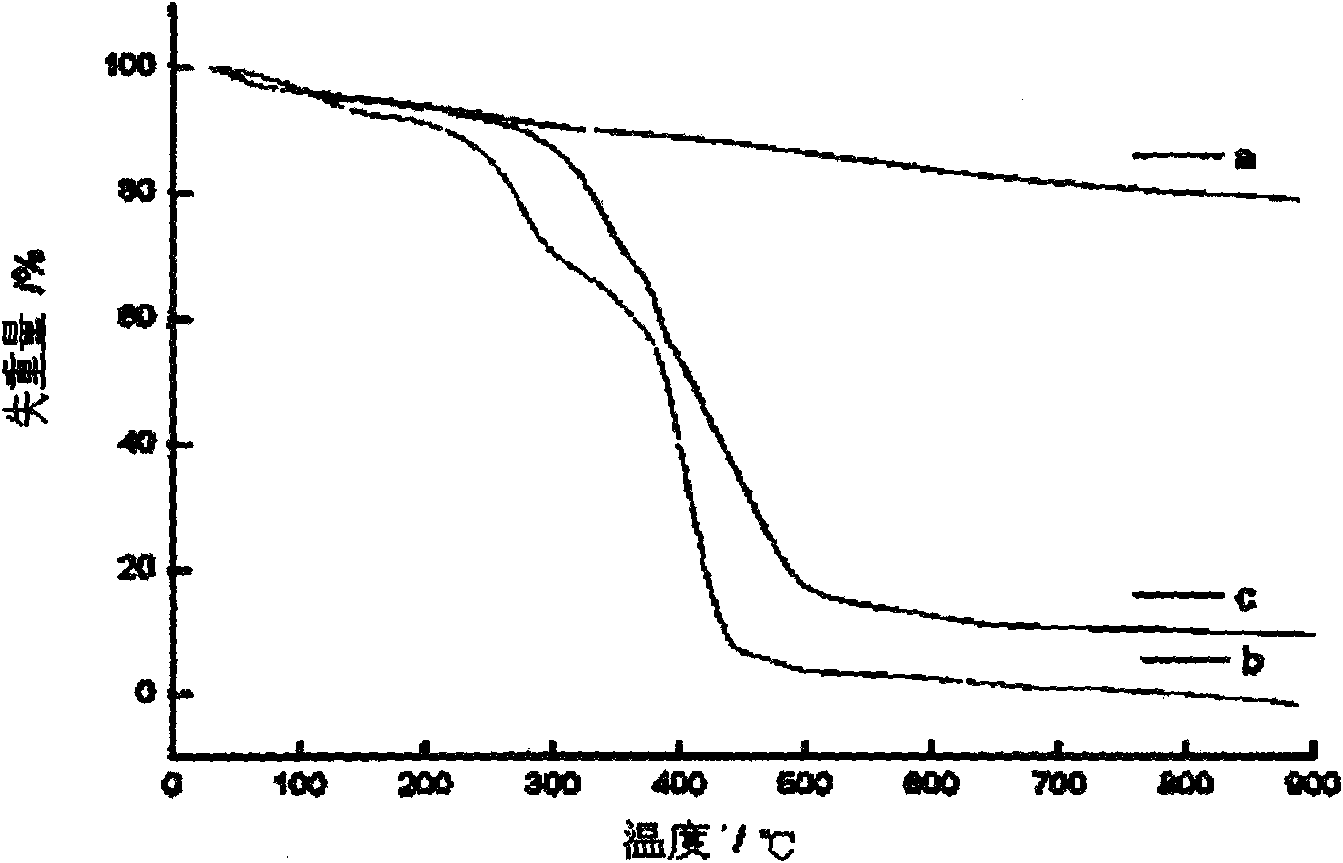

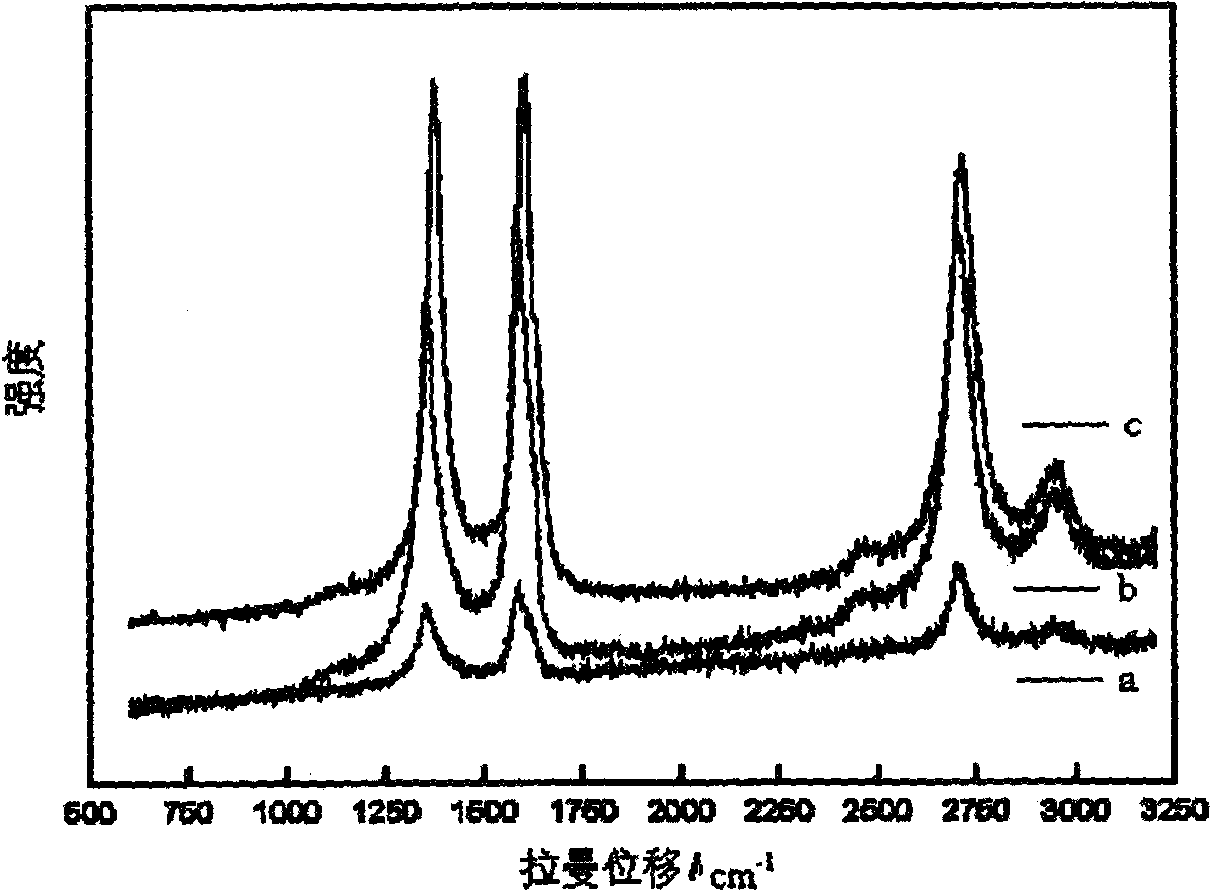

[0022] Take 100mg mixed strong acid (V 浓H2SO4 :V 浓HNO3 =3: 1) carbon nanotubes after oxidation (multi-walled carbon nanotubes, d=10~50nm, l=1~50μm, Beijing Nachen Co., Ltd., the same below) were treated with 14W of discharge power and Ar plasma for 5min, Then add 5g of acrylic acid monomer and 15g of deionized water into a three-necked flask, protect with Ar, stir, heat up to 41°C for 3h, collect the product, wash with acetone or ethanol for 3 times, and wash the product at room temperature under vacuum Dry for 3 hours to obtain polypropionic acid-modified carbon nanotubes. Thermogravimetric analysis found that functional groups grafted onto the surface of carbon nanotubes accounted for 26.5% of the total. Raman spectroscopy indicated that polyacrylic acid was attached to carbon nanotubes.

[0023] figure 1 Thermal weight loss diagram of polyacrylic acid modified carbon nanotubes, a-MWCNTs after strong acid oxidation, b-PAA modified MWCNTs, c-PAA. figure 2 Dispersion dia...

example 2

[0025] Take 100mg of carbon nanotubes oxidized by mixed strong acid and treat them with Ar plasma at a discharge power of 14W for 5min, then add them together with 5g of acrylic acid monomer and 15g of deionized water into a three-necked flask, protect with Ar, stir, and heat up to 51°C for reaction After 3 hours, the product was collected, washed three times with acetone or ethanol, and the washed product was dried under vacuum at room temperature for 3 hours to obtain polyacrylic acid-modified carbon nanotubes. Thermogravimetric analysis found that functional groups grafted onto the surface of carbon nanotubes accounted for 71.5% of the total. Raman spectroscopy indicated that polyacrylic acid was attached to carbon nanotubes.

example 3

[0027] Take 100mg of carbon nanotubes oxidized by a mixed strong acid and treat them with Ar plasma at a discharge power of 14W for 5 minutes, then add them together with 5g of acrylic acid monomer and 15g of deionized water into a three-necked flask, protect them with Ar, stir, and heat up to 41°C for reaction After 4 hours, the product was collected, washed three times with acetone or ethanol, and the washed product was dried under vacuum at room temperature for 3 hours to obtain polyacrylic acid-modified carbon nanotubes. Thermogravimetric analysis found that functional groups grafted onto the surface of carbon nanotubes accounted for 41.3% of the total. Raman spectroscopy indicated that polyacrylic acid was attached to carbon nanotubes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com