Aluminum alloy complex disc part isothermal precision forging die

A disc-type part, isothermal precision forging technology, applied in the field of warm forging die, can solve the problems of flow through, flow line disorder, difficult to fill metal, etc., to improve flow line, uniform and fine grain size, and avoid flow line folding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

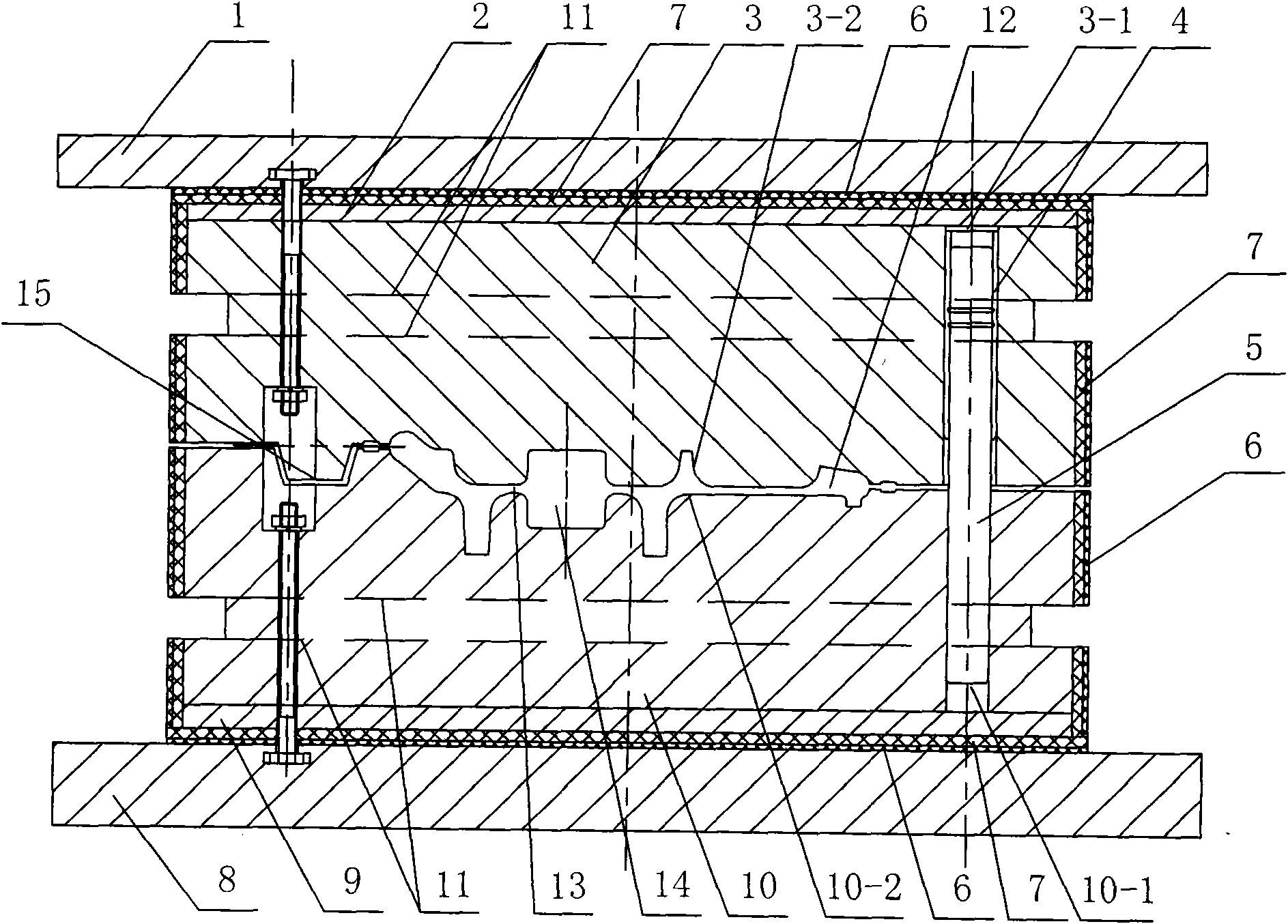

[0007] Specific implementation mode one: combine figure 1 To illustrate this embodiment, the isothermal precision forging die for complex aluminum alloy disk parts of this embodiment includes an upper backing plate 2, an upper forging die 3, a lower backing plate 9, a lower forging die 10, a guide sleeve 4 and a guide post 5, the The upper forging die 3 is fixedly mounted on the upper workbench 1 of the press, and an upper backing plate 2 is arranged between the upper forging die 3 and the upper workbench 1 of the press, the lower forging die 10 is fixedly installed on the lower workbench 8 of the press, and the lower forging A lower backing plate 9 is provided between the mold 10 and the lower working table 8 of the press, and a guide sleeve installation hole 3-1 is opened on the upper forging die 3, and the guide sleeve 4 is fixedly installed in the guide sleeve installation hole 3-1. The lower forging die 10 is provided with a guide post installation hole 10-1, the lower en...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 The present embodiment will be described. The parting surface 15 of the precision forging die of the present embodiment adopts a stepped parting surface. The parting surface 15 is the interface between the upper forging die 3 and the lower forging die 10 . Such setting saves one-third of the working pressure and greatly improves the filling quality of the material. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 1 The present embodiment will be described. The aluminum silicate plate 7 of the present embodiment has a thickness of 3 mm to 7 mm, and the asbestos plate 6 has a thickness of 20 mm to 30 mm. With such setting, the thermal insulation effect is better. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com