Arachidonic acid nutrition microcapsule with high temperature resistance and preparation method thereof

A technology of arachidonic acid and microcapsules, applied in microcapsules, food preparation, capsule transportation, etc., can solve the problems of high temperature resistance, difficulty, easy oxidation, etc., and achieve product shelf life extension and heat resistance enhancement. , good heat resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The weight percentages of the materials are as follows:

[0029] Arachidonic Acid 15%,

[0030] Capsule material I: maltodextrin 60%,

[0031] Antioxidants: Vitamin C 2%,

[0032] Capsule material II: octenyl succinate starch 23%.

[0033] The preparation method is as follows:

[0034] (1) Dissolving the capsule material I and the antioxidant in hot water at 60°C, stirring and melting, then cooling down to 30°C, the amount of hot water being twice the total weight of the capsule material I and the antioxidant;

[0035] (2) Add arachidonic acid to the mixture obtained in step (1), perform embedding for the first time, and stir for 20 minutes until uniformly mixed;

[0036] (3) The mixture obtained in step (2) is subjected to high-pressure homogeneous emulsification for the second time, emulsified at 15Mpa for 8 minutes for the first time, and emulsified at 25Mpa for 25 minutes for the second time;

[0037] (4) Add capsule material II to the emulsion obtained in step...

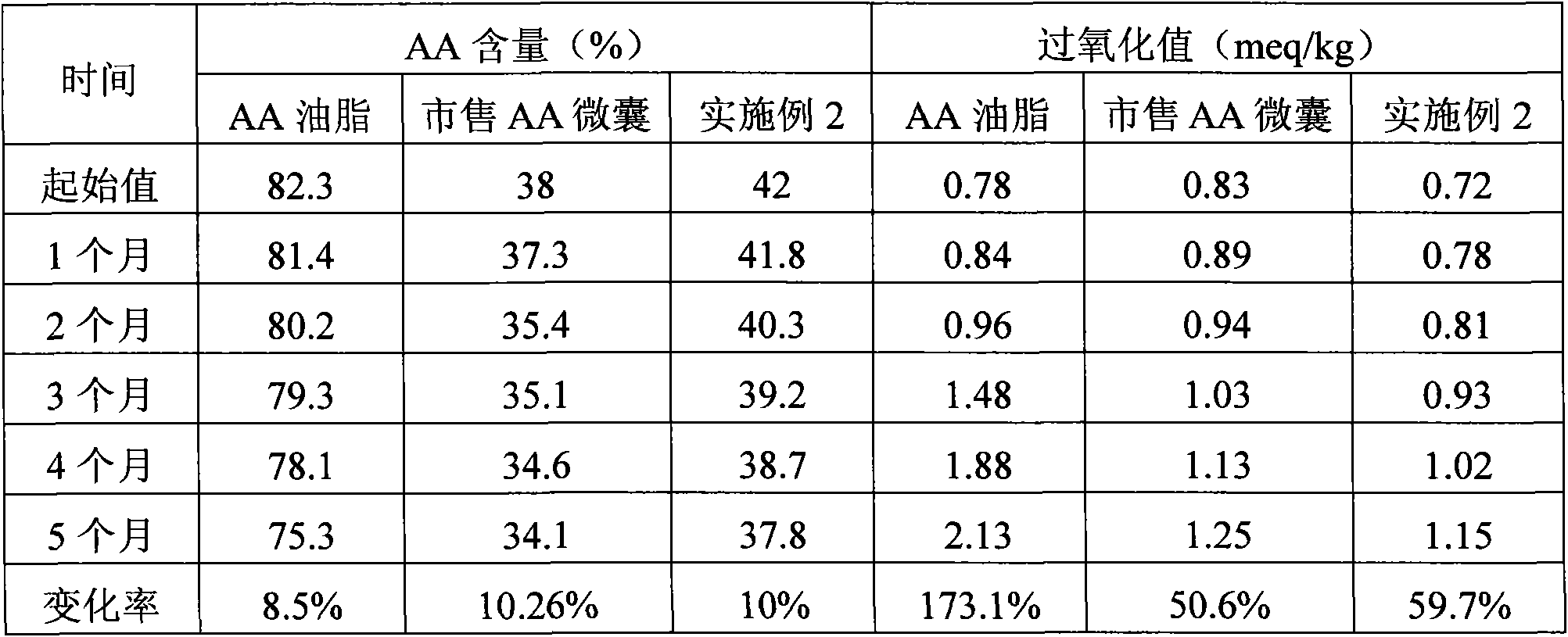

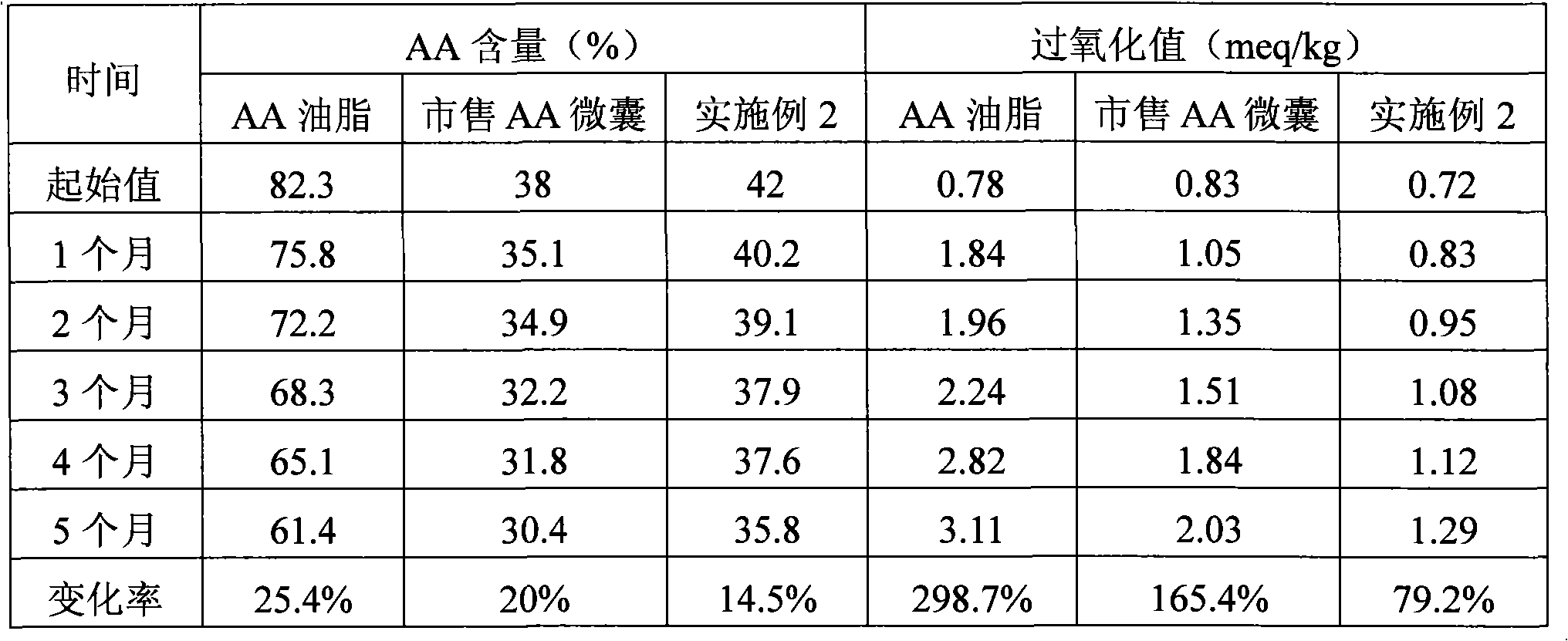

Embodiment 2

[0041] The weight percentages of the materials are as follows:

[0042] Arachidonic Acid 30%,

[0043] Capsule material I: Hydroxypropyl cellulose 40%,

[0044] Antioxidant: Vitamin E 1%,

[0045] Capsule II: Gum Arabic 29%.

[0046] The preparation method is as follows:

[0047] (1) Dissolving the capsule material I and the antioxidant in hot water at 70°C, stirring and melting, then cooling down to 35°C, the amount of hot water being 3 times the total weight of the capsule material I and the antioxidant;

[0048] (2) Add arachidonic acid to the mixture obtained in step (1), perform embedding for the first time, and stir for 30 minutes until uniformly mixed;

[0049] (3) The mixture obtained in step (2) is subjected to high-pressure homogeneous emulsification for the second time, emulsified at 15Mpa for 5 minutes for the first time, and emulsified at 30Mpa for 25 minutes for the second time;

[0050] (4) Add capsule material II to the emulsion obtained in step (3), perfo...

Embodiment 3

[0054] The weight percentages of the materials are as follows:

[0055] Arachidonic Acid 30%,

[0056] Capsule material I: cyclodextrin 30%, hydroxypropyl cellulose 25%,

[0057] Antioxidants: Tea Polyphenols 1%, Vitamin E, 1%,

[0058] Capsule material II: Gelatin 10%, corn dextrin 3%.

[0059] The preparation method is as follows:

[0060] (1) Dissolving the capsule material I and the antioxidant in hot water at 60°C, stirring and melting, then cooling down to 35°C, the amount of hot water being 4 times the total weight of the capsule material I and the antioxidant;

[0061] (2) Add arachidonic acid to the mixture obtained in step (1), perform embedding for the first time, and stir for 30 minutes until uniformly mixed;

[0062] (3) The mixture obtained in step (2) is subjected to high-pressure homogeneous emulsification for the second time, emulsified at 20Mpa for 10 minutes for the first time, and emulsified at 25Mpa for 25 minutes for the second time;

[0063] (4) Add c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com