Method for preparing SiCf/SiC compound material by combination of chemical vapor carbon deposition process and gas phase siliconizing process

A chemical vapor deposition and vapor silicon infiltration technology is applied in the field of preparation of SiC-based composite materials, which can solve the problems of affecting application and lack of plastic deformation ability, and achieve the effects of reducing production cost, shortening production cycle and high density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A kind of chemical vapor deposition carbon of the present invention and vapor phase siliconizing process are combined to prepare SiC f / SiC composite material method, comprising the following steps:

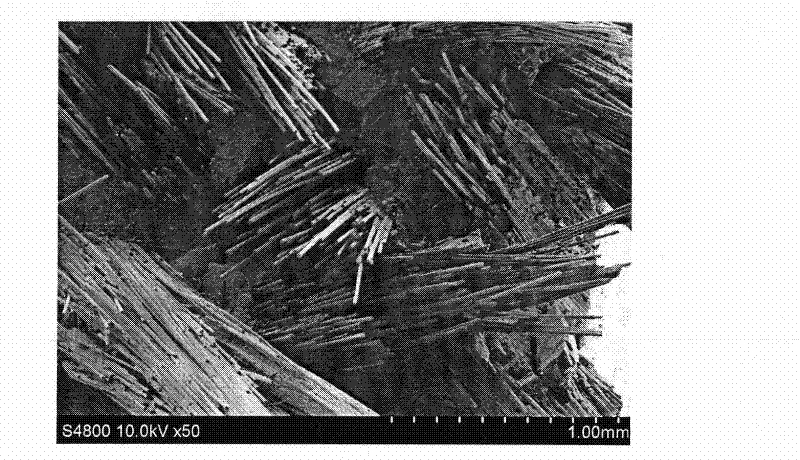

[0019] 1. SiC fiber weaving: SiC fiber is used as raw material, and SiC fiber braided parts are prepared by three-dimensional weaving process;

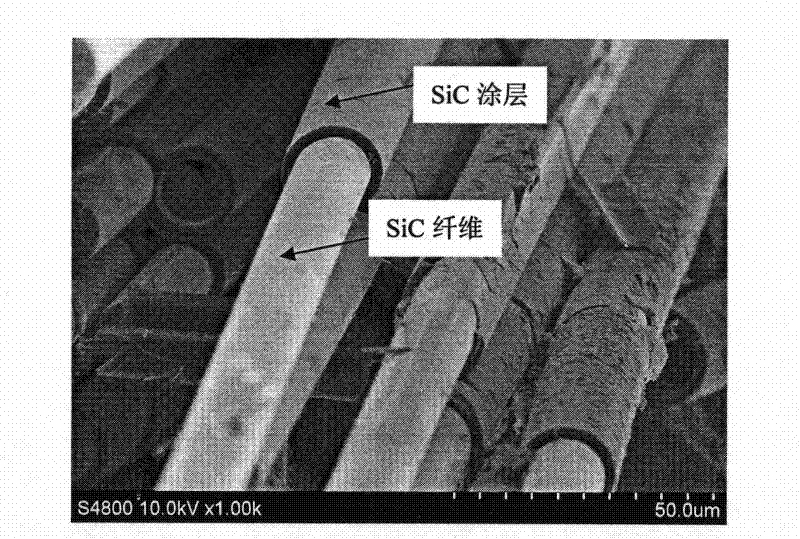

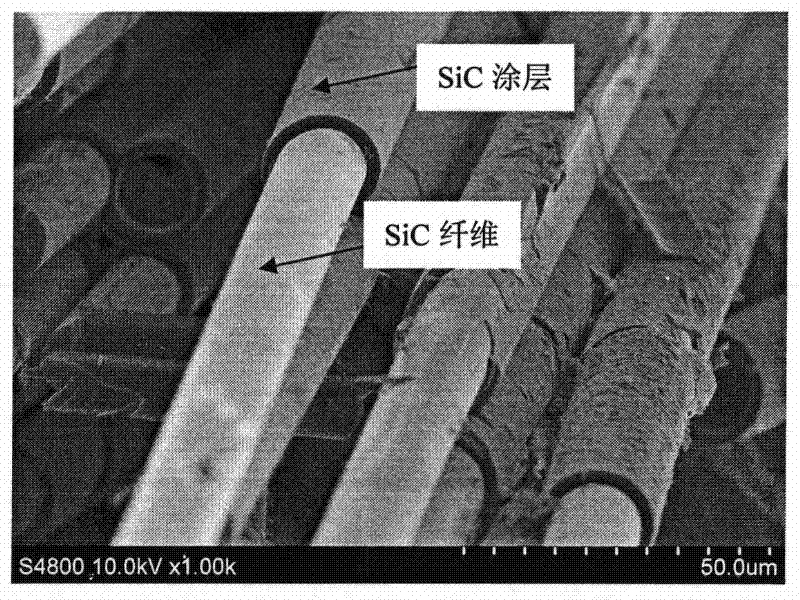

[0020] 2. Chemical vapor deposition SiC coating: place the SiC fiber braid prepared above in a vacuum furnace for the first chemical vapor deposition, the deposition raw material (ie precursor) is trichloromethylsilane, and the deposition temperature is 1150°C; The carrier gas is H 2 , H 2 The flow rate is 0.01m 3 h -1 ; The dilution gas is argon, and the flow rate of argon is 0.03m 3 h -1 ; The deposition pressure is 5kPa, the deposition time is 40h, and the thickness of the SiC coating obtained after deposition is 20 μm;

[0021] 3. Chemical vapor deposition of carbon: using propylene gas as a raw material, carbon is depo...

Embodiment 2

[0026] A kind of chemical vapor deposition carbon of the present invention and vapor phase siliconizing process are combined to prepare SiC f / SiC composite material method, comprising the following steps:

[0027] 1. SiC fiber weaving: SiC fiber is used as raw material, and SiC fiber braided parts are prepared by three-dimensional weaving process;

[0028] 2. Chemical vapor deposition SiC coating: place the SiC fiber braid prepared above in a vacuum furnace for the first chemical vapor deposition, the deposition raw material is trichloromethylsilane, the deposition temperature is 1300 °C; the carrier gas is H 2 , H 2 The flow rate is 0.2m 3 h -1 ; The dilution gas is argon, and the flow rate of argon is 0.6m 3 h -1 ; The deposition pressure is 5kPa, the deposition time is 10h, and the thickness of the SiC coating obtained after deposition is 5 μm;

[0029] 3. Chemical vapor deposition of carbon: using propylene gas as a raw material, carbon is deposited on the SiC fiber b...

Embodiment 3

[0034] A kind of chemical vapor deposition carbon of the present invention and vapor phase siliconizing process are combined to prepare SiC f / SiC composite material method, comprising the following steps:

[0035] 1. SiC fiber weaving: SiC fiber is used as raw material, and SiC fiber braided parts are prepared by three-dimensional weaving process;

[0036] 2. Chemical vapor deposition SiC coating: place the SiC fiber braid prepared above in a vacuum furnace for the first chemical vapor deposition, the deposition raw material (ie precursor) is trichloromethylsilane, and the deposition temperature is 1500°C; The carrier gas is H 2 , H 2 The flow rate is 0.1m 3 h -1 ; The dilution gas is argon, and the flow rate of argon is 0.3m 3 h -1 ; The deposition pressure is 5kPa, the deposition time is 40h, and the thickness of the SiC coating obtained after deposition is 30 μm;

[0037] 3. Chemical vapor deposition of carbon: using methane gas as a raw material, carbon is deposite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com