InP base plane type back incident avalanche optoelectronic diode and manufacturing method thereof

A technology of avalanche optoelectronics and manufacturing methods, which is applied to circuits, electrical components, semiconductor devices, etc., and can solve problems such as good uniformity, difficult manufacturing, and difficult realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

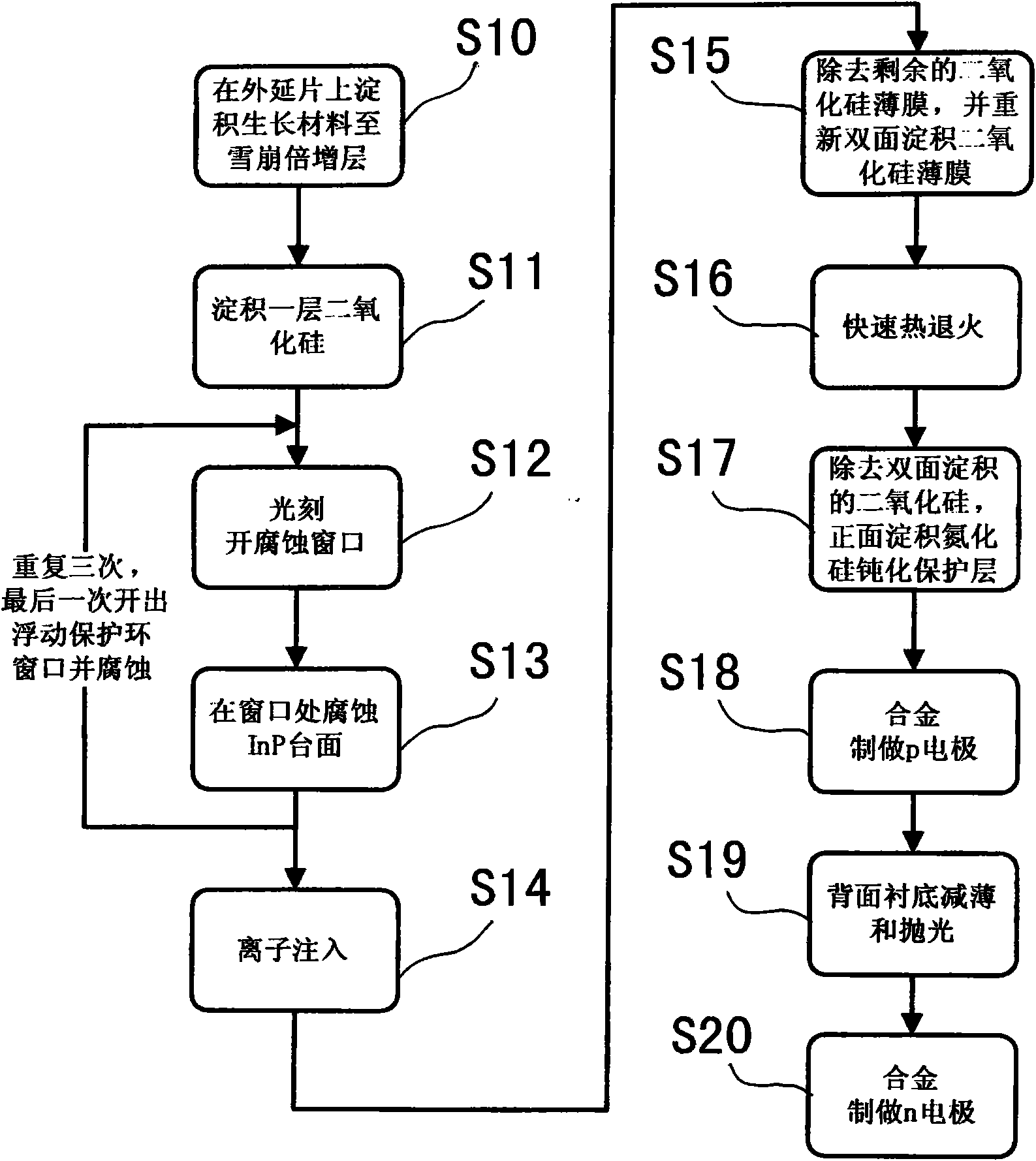

Method used

Image

Examples

Embodiment Construction

[0040] see figure 1 Shown, a kind of InP base planar type back-incidence avalanche photodiode of the present invention comprises:

[0041] a substrate 10;

[0042] A buffer layer 20, the buffer layer 20 is fabricated on the substrate 10;

[0043] An absorption layer 30, the absorption layer 30 is made on the buffer layer 20, and the absorption layer 30 is InGaAs;

[0044] A transition layer 40, the transition layer 40 is made on the absorption layer 30, and the transition layer 40 is InGaAsP;

[0045] An electric field control layer 50, the electric field control layer 50 is fabricated on the transition layer 40;

[0046] An avalanche multiplication layer 60, the avalanche multiplication layer 60 is fabricated on the electric field control layer 50;

[0047] Wherein the central region above the avalanche multiplication layer 60 is formed with a recessed portion 61, the edge of the recessed portion 61 is an inverted stepped structure; the outer side of the upper recessed po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com