Preparation method of chitosan fiber

A chitosan fiber and chitosan technology, which is applied in fiber treatment, spinning solution preparation, fiber chemical characteristics, etc., can solve the problems of polluting the three wastes, difficult to recycle, easy to volatilize solvents, etc., and achieves easy operation and high performance. Stable, mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Chitosan raw material: 200CPS (when the concentration of glacial acetic acid is 1%), the degree of deacetylation is 90%, and the ash content is 0.3%.

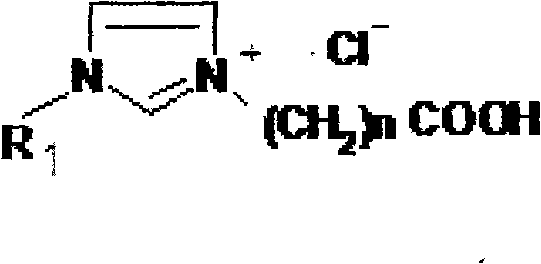

[0042] Take 70g of 10% 1-acetoxy-3-methylimidazolium chloride ionic liquid aqueous solution, slowly add 2.10g of chitosan at normal temperature and pressure, and stir for 8-10 hours. After the chitosan is completely dissolved, filter twice with a 600-mesh filter cloth, and degas under reduced pressure to obtain a light yellow transparent chitosan spinning solution. Put the chitosan solution into the spinning kettle, extrude the chitosan solution at an extrusion speed of 0.03m / s, and then enter the coagulation bath with 3% sodium sulfate at a temperature of 50°C, and enter at a temperature of 70°C. ℃ stretching bath, and finally dried at a certain temperature to obtain white chitosan fibers.

Embodiment 2

[0044] Chitosan raw material: 500CPS (when the concentration of glacial acetic acid is 1%), the degree of deacetylation is 86%, and the ash content is 0.4%.

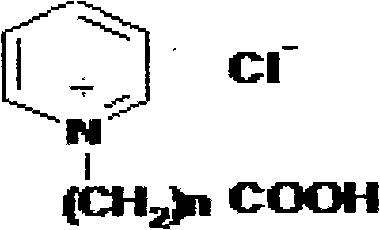

[0045] Take 80 g of 2% N-acetic acid pyridinium chloride ionic liquid aqueous solution, slowly add 1.60 g of chitosan at normal temperature and pressure, and stir for 10 to 12 hours. After the chitosan is completely dissolved, filter twice with a 600-mesh filter cloth, and degas under reduced pressure to obtain a light yellow transparent chitosan spinning solution. The chitosan solution is transferred into the spinning kettle, and the chitosan solution is extruded at an extrusion speed of 0.5m / s, and then enters into a 50% N-acetic acid pyridinium chloride ionic liquid aqueous solution at a temperature of coagulation bath at 60°C, washed in a stretching bath at a temperature of 70°C, and finally dried at a certain temperature to obtain white chitosan fibers.

Embodiment 3

[0047] Chitosan raw material: 300CPS (when the concentration of glacial acetic acid is 1%), the degree of deacetylation is 90%, and the ash content is 0.4%.

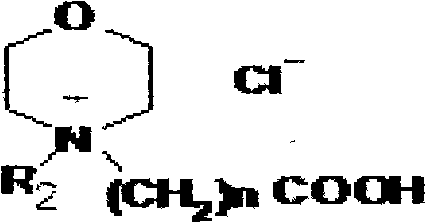

[0048]Take 70 g of 15% N-butyric acid pyrrole chloride ionic liquid aqueous solution, slowly add 2.55 g of chitosan at normal temperature and pressure, and stir for 10 to 12 hours. After the chitosan is completely dissolved, filter twice with an 800-mesh filter cloth, and degas under reduced pressure to obtain a light yellow transparent chitosan spinning solution. The chitosan solution is transferred into the spinning kettle, and the chitosan solution is extruded at an extrusion speed of 0.02m / s, and then enters the solution filled with 50% N-butyric acid pyrrole chloride ionic liquid aqueous solution, temperature It is a coagulation bath at 60°C, washed in a stretching bath at a temperature of 70°C, and finally dried at a certain temperature to obtain white chitosan fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com