Preparation method of colourful electrophoresis disclosing solution for electronic ink display

A technology of color electrophoresis and electronic ink, which is applied in the field of preparation of color electrophoretic display liquid, can solve the problems of inconspicuous color contrast, easy sedimentation of electrophoretic particles, long response time, etc., and achieves easy separation process, simple and easy preparation process, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

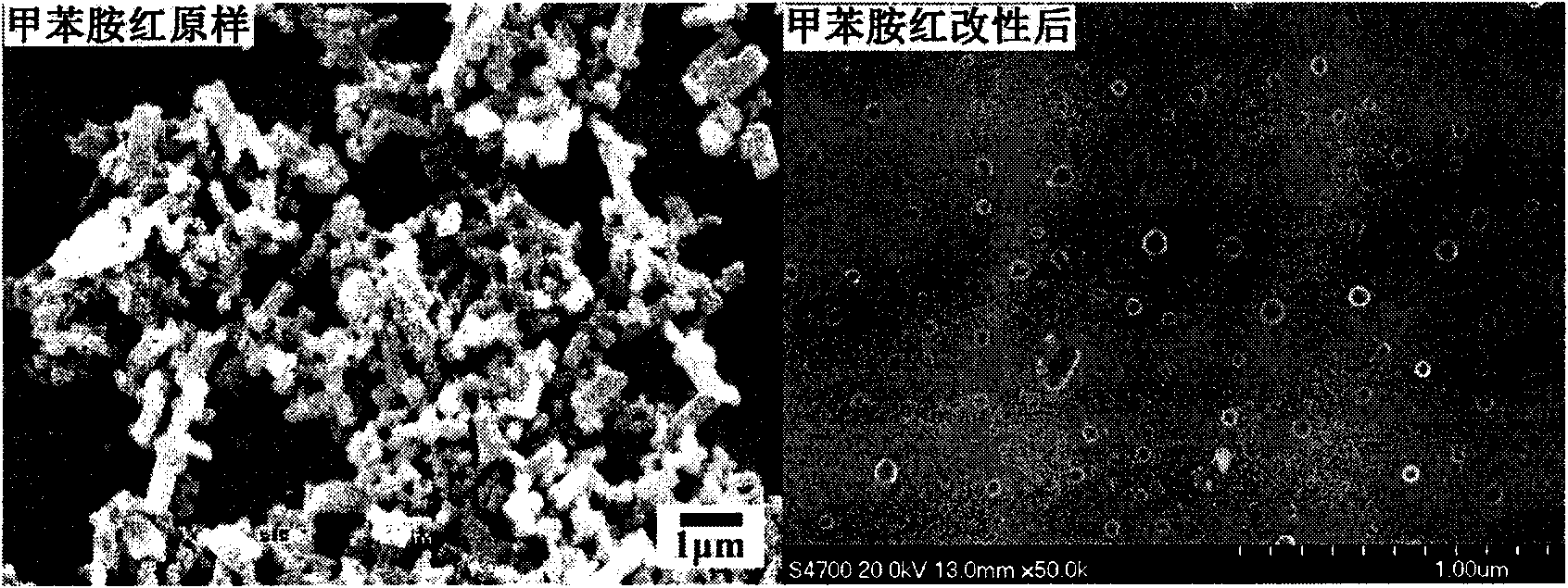

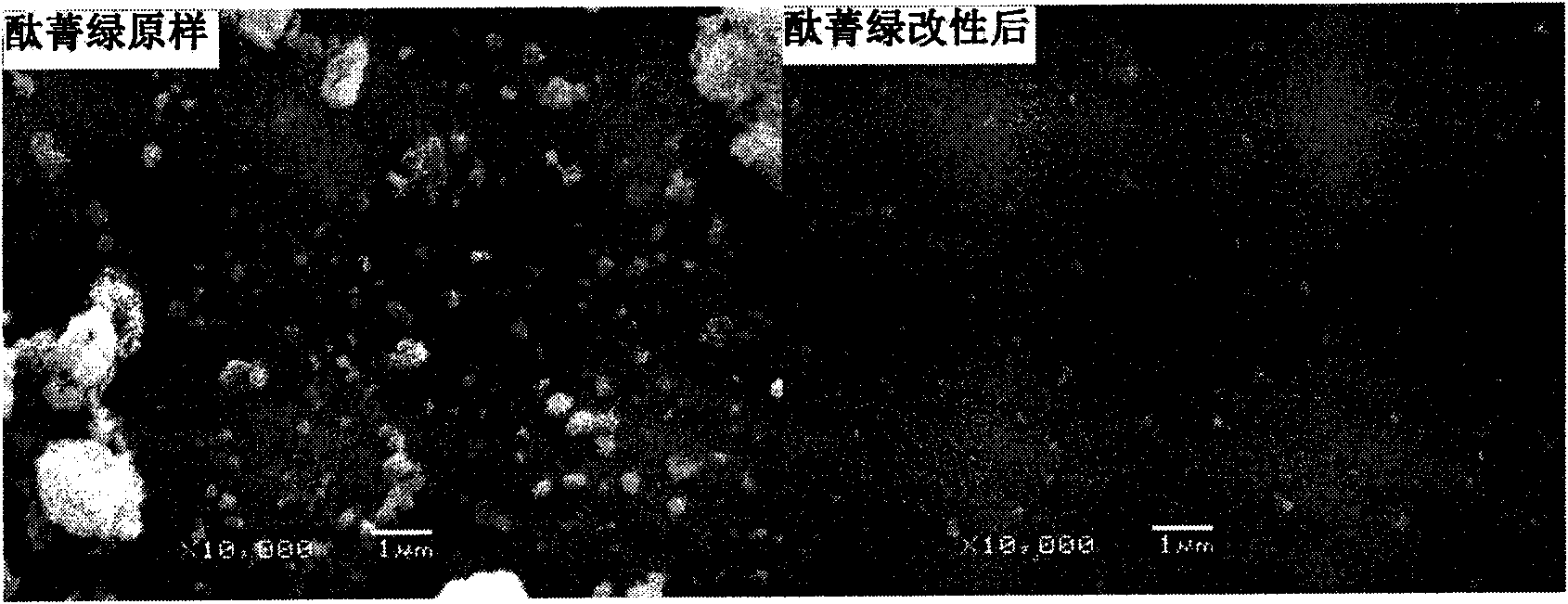

[0036] (1) Weigh 0.03g of toluidine red and dissolve in 10mL of absolute ethanol;

[0037] (2) Weigh 0.05g of sodium dodecyl sulfate (SDS) into 200mL of deionized water, stir magnetically for 20min, and add it into a 250mL three-necked flask after being dissolved. Control stirring speed to be 600rpm, start to stir.

[0038] (3) Add the toluidine red-ethanol solution in (1) dropwise to the three-necked flask in (2) at room temperature and under stirring conditions for recrystallization and modification, and react for 20 minutes.

[0039] (4) Add 10 mL of tetrachlorethylene to the suspension in (3) above, continue to stir for 10 minutes, and then let it stand for 10 minutes. The toluidine red is extracted into the tetrachlorethylene, and the layers are separated, and the lower layer is removed. That is, the modified toluidine red-tetrachloroethylene suspension is obtained.

[0040] (5) Add 0.02g hyperdispersant CH-6 to the lower layer solution obtained in (4), stir magneticall...

Embodiment 2

[0044] (1) Weigh 0.05g of toluidine red and dissolve in 10mL of tetrahydrofuran;

[0045] (2) Measure 1mL of Span-80 (mass 1.1g) into 200mL of deionized water, stir magnetically for 20min, and add to a 250mL three-neck flask after dissolution. Control stirring speed to be 900rpm, start to stir.

[0046] (3) Add the toluidine red-tetrahydrofuran solution in (1) dropwise to the three-neck flask in (2) at room temperature and under stirring conditions for recrystallization and modification, and react for 15 minutes.

[0047] (4) Add 8mL tetrachlorethylene and 2.5mL cyclohexane to the suspension of the above (3) as a compound dispersion medium, continue to stir for 10min, then stand for 10min, the toluidine red is extracted into the compound system, To layer, remove layers. That is, the modified toluidine red-tetrachloroethylene / cyclohexane suspension is obtained.

[0048] (5) Add 0.05 g of dispersant UV681 to the lower layer solution obtained in (4), stir magnetically for 30 m...

Embodiment 3

[0052] (1) Weigh 0.03g of toluidine red, dissolve it in 5mL of concentrated sulfuric acid (mass concentration is 98%), and stir it with a glass rod to fully dissolve it;

[0053] (2) Measure 100 mL of deionized water as an anti-solvent, measure 1 mL of alkyl hydroxamic acid (0.75 g in mass) and add it to 2 mL of ethanol. Add to a 250mL three-neck flask. Control stirring speed to be 800rpm, start to stir.

[0054] (3) Add the toluidine red-concentrated sulfuric acid solution in (1) dropwise to the three-necked flask in (2) at room temperature and under stirring conditions for recrystallization and modification, and react for 20 minutes.

[0055] (4) Add 8 mL of carbon tetrachloride to the suspension in (3) above, continue to stir for 10 minutes, then let it stand for 10 minutes, the toluidine red is extracted into the carbon tetrachloride, separate the layers, and remove the lower layer. That is, the modified toluidine red-carbon tetrachloride suspension is obtained.

[0056...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com