Method for melt spinning of polyacrylonitrile PAN by taking imidazole ionic fluid as plasticizing agent

An ionic liquid, polyacrylonitrile technology, applied in the direction of melt spinning, spinning solution preparation, single-component synthetic polymer rayon, etc., can solve the narrow melt spinning temperature range of hydrated melt, difficult process control, The mechanical properties of fibers are deteriorated and other problems, so as to save the solvent recovery process, equipment and water washing process, eliminate serious environmental pollution problems, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] First, polyacrylonitrile powder and [BMIM]BF 4 Mix evenly in a high-speed mixer with a mass ratio of 1:1, and then transfer to a twin-screw spinning machine for melt spinning; the screw speed of the twin-screw spinning machine is 50r / min, and the temperature of the feed section is set to 185°C. The temperature of the plasticizing section is 190°C, the temperature of the melting section is 185°C, the aspect ratio of the spinneret is 1:3, and the hole diameter is 0.5mm. The spun filaments are subjected to primary dry heat stretching, secondary dry heat stretching, Washing, oiling, and heat setting to obtain PAN fiber. The PAN fiber strength is 2.8cN / dtex, and the elongation at break is 19.0%.

Embodiment 2

[0030] First, polyacrylonitrile powder and [EMIM]BF 4 Mix evenly in a high-speed mixer at a mass ratio of 1.2:1, and then transfer to a twin-screw spinning machine for melt spinning. Adjust the screw speed of the twin-screw spinning machine to 75r / min, the temperature of the feed section to 180°C, the temperature of the plasticizing section to 185°C, the temperature of the melting section to 180°C, the length-to-diameter ratio of the spinneret to 1:3, and the aperture to 0.5mm, the spun filaments are subjected to primary dry heat stretching, secondary dry heat stretching, washing, oiling, and heat setting to obtain PAN fibers. The PAN fiber strength is 3.6cN / dtex, and the elongation at break is 10.9%.

Embodiment 3

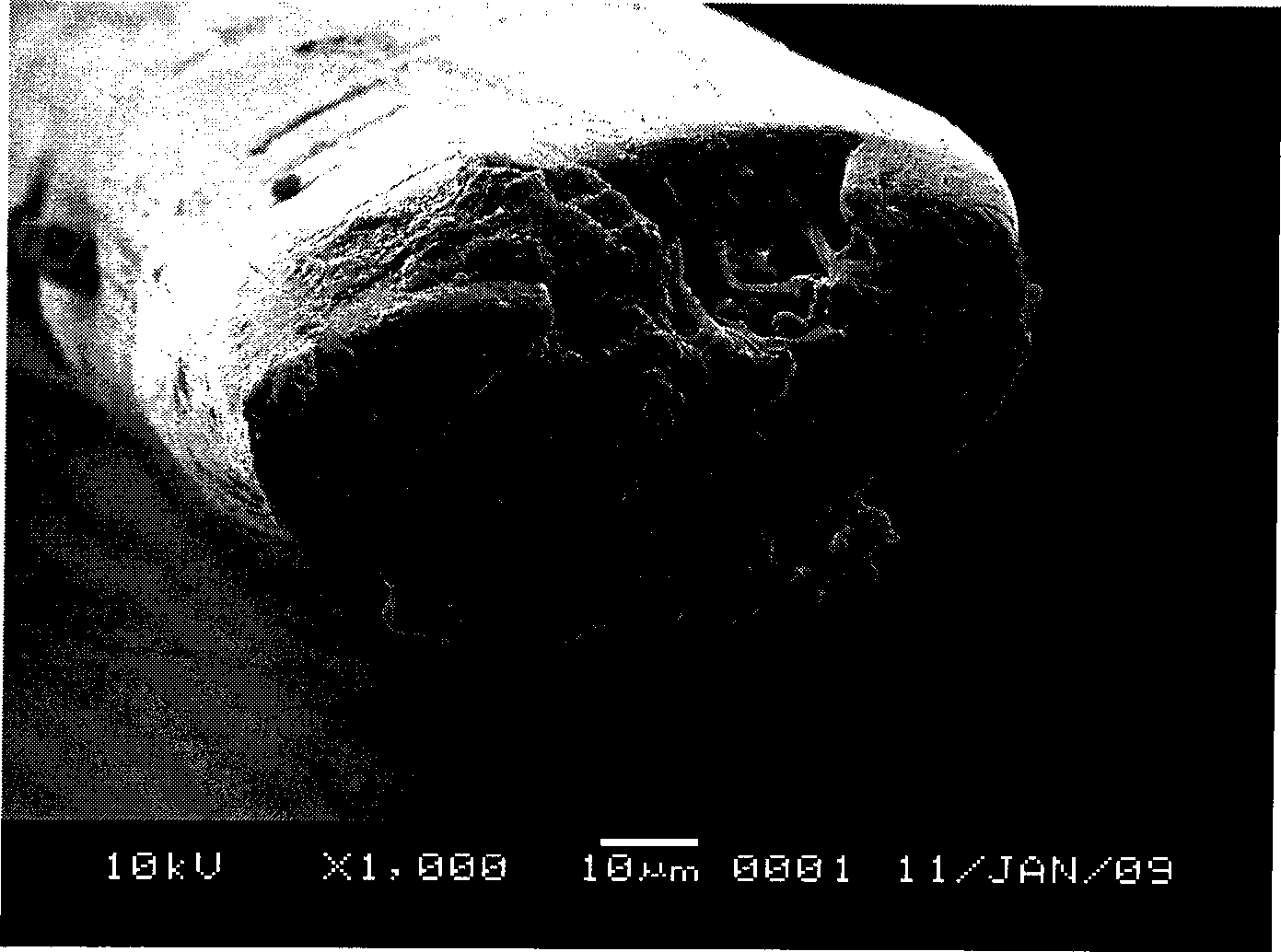

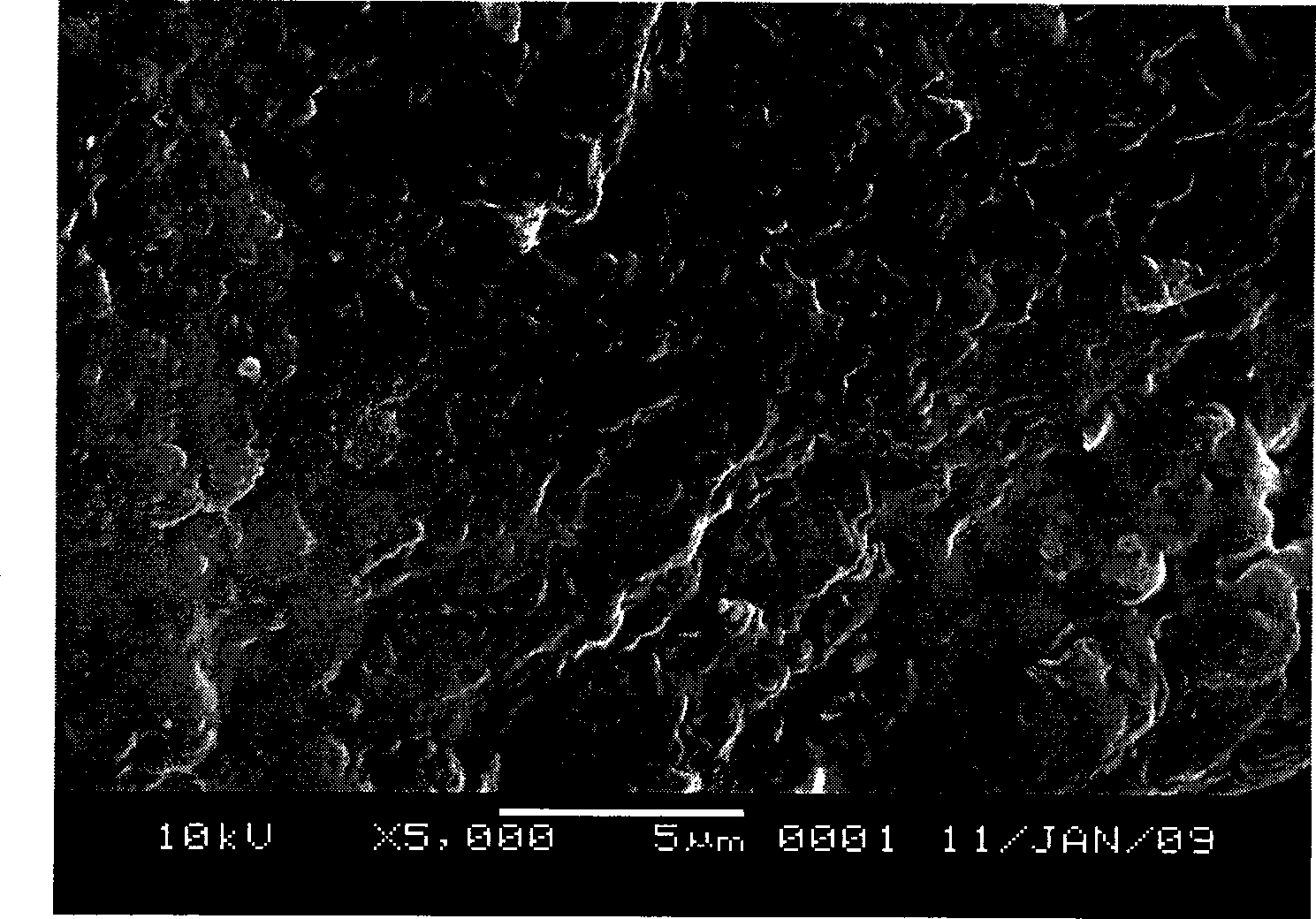

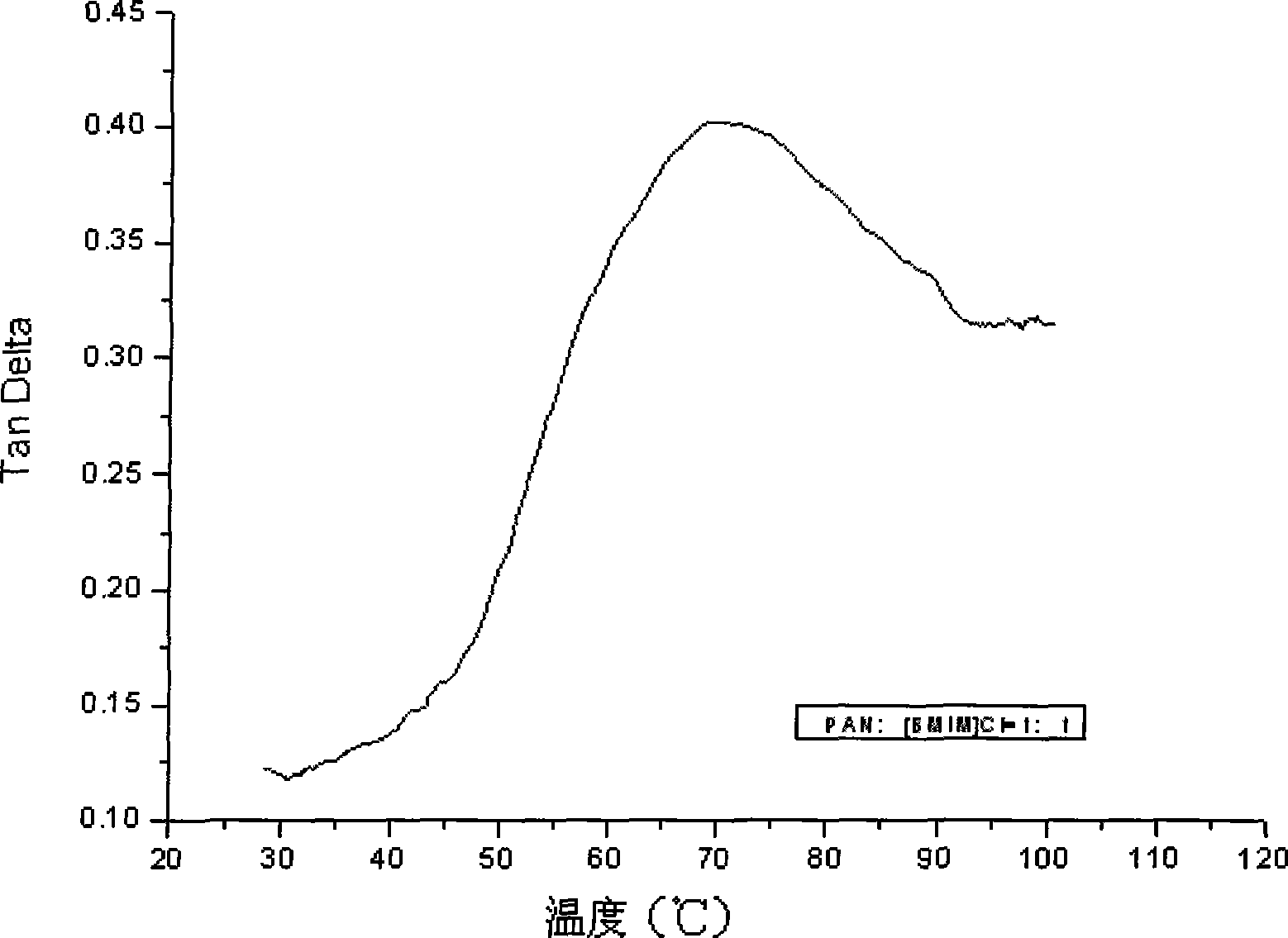

[0032]First, the polyacrylonitrile powder and [BMIM]Cl were mixed uniformly in a high-speed mixer at a mass ratio of 1:1, and then transferred to a twin-screw spinning machine for melt spinning. Adjust the screw speed of the twin-screw spinning machine to 70r / min, the temperature of the feed section to 185°C, the temperature of the plasticizing section to 190°C, the temperature of the melting section to 190°C, the length-to-diameter ratio of the spinneret to 1:3, and the hole diameter to be 0.5mm, the spun silk is subjected to primary dry heat stretching, secondary dry heat stretching, washing, oiling, and heat setting to obtain PAN fibers. The strength of PAN fibers is 4.0cN / dtex, and the elongation at break is 16.9 %. Figure 1 is the SEM photo of the PAN fiber cross-section after washing. figure 2 is the DMA curve of PAN fiber when PAN / [BMIM]Cl is 1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com