Cobalt-based bulk amorphous alloy and preparation method thereof

An amorphous alloy and bulk technology, which is applied in the field of cobalt-based bulk amorphous alloy materials and its preparation, can solve the problems of small maximum block diameter of cobalt-based amorphous, achieve excellent soft magnetic properties, and overcome the complex processing technology. , the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 prepares Co 46 Fe 20 B 22 Si 6 Nb 6 large piece of metallic glass

[0029] After the Co, Fe, B, Si, Nb components with a purity of not less than 99wt% (weight percent) are prepared in a molar ratio of 46:20:22:6:6, they are mixed in an electric arc furnace with an argon atmosphere And smelt 3-4 times, get Co after cooling 46 Fe 20 B 22 Si 6 Nb 6 Master alloy ingot; then use the vacuum copper mold casting method to melt the ingot again, and press the master alloy melt into the copper mold to obtain the composition of Co 46 Fe 20 B 22 Si 6 Nb 6 , a bulk amorphous alloy with a diameter of 4 mm.

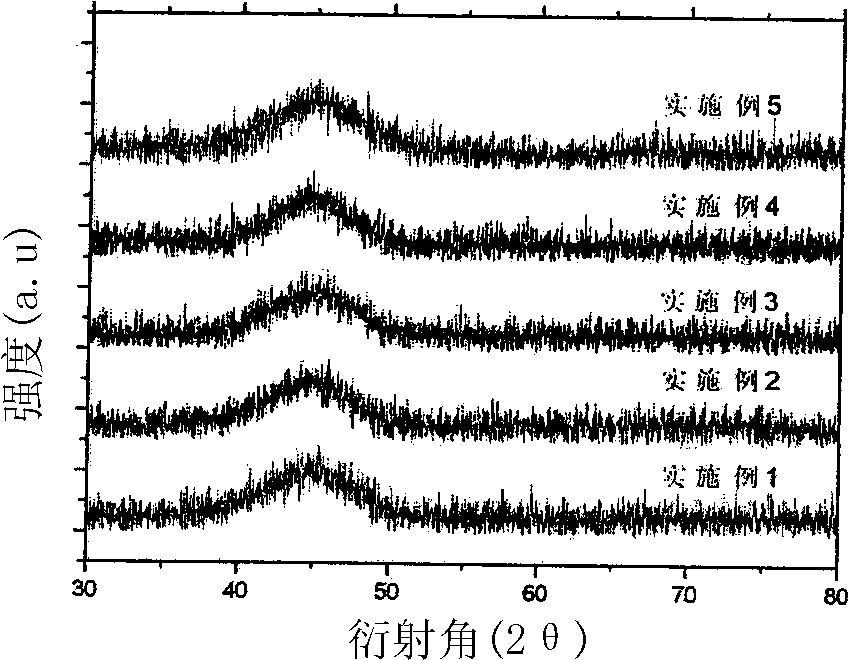

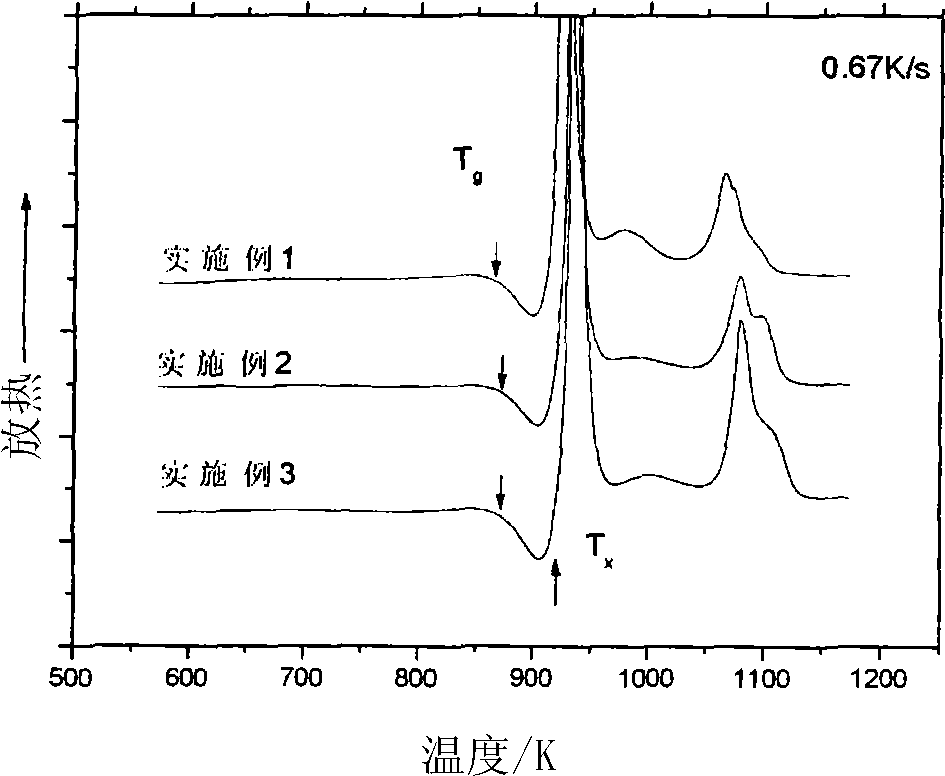

[0030] From such as figure 1 The shown X-ray diffraction (XRD) can prove that Co 46 Fe 20 B 22 Si 6 Nb 6 The alloy is a completely amorphous alloy. figure 2 is the physical photo of the prepared amorphous rod, where Co 46 Fe 20 B 22 Si 6 Nb 6 The bulk amorphous rod has a diameter of 4 mm. image 3 and Figure 4 for Co 46 Fe 20 B 22 Si ...

Embodiment 2-14

[0031] Example 2-14. Cobalt-based bulk amorphous alloys prepared in various proportions

[0032] Cobalt-based bulk amorphous alloys with various ratios were prepared according to the method of Example 1, and their compositions and thermophysical parameters are listed in Table 1.

[0033] Note: 1) The symbols in the table have the following meanings:

[0034] D——sample diameter under the experimental conditions; T g——Glass transition temperature; △T——Width of supercooled liquid phase region; T 1 - liquidus temperature; T rg ——reduced glass temperature (T rg =T g / T 1 );H c ——coercive force; μ e ——effective magnetic permeability; M s - Saturation magnetization.

[0035] Table 1. Composition, thermophysical and magnetic performance parameters of the cobalt-based bulk amorphous alloy of various proportionings of the present invention

[0036] Example alloy composition D(mm) T g (K) △T T 1 (K) T rg h c (A / m) mu e (1kHz, 1A / m) m s (T) 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com