N-containing Be-free Ni-free high-hardness Zr matrix body amorphous alloy and preparation method thereof

An amorphous alloy and base block technology, which is applied in the field of Be-free, Ni-free and high-hardness Zr-based bulk amorphous alloys, can solve the problems of low hardness of Zr-based amorphous alloys, and achieve excellent biocompatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Preparation and Properties of Zr-Cu-Ti-X-N Series Bulk Amorphous Alloy

[0027] Design the composition of Zr-Cu-Ti-X-N bulk amorphous alloy, and in order to reflect the influence of N microalloying on the amorphous, the inventor also prepared nitrogen-free Zr-Cu-Ti- X alloy. Zr-Cu-Ti-X is only used as a reference alloy, but it is not within the scope of this patent requirement, so it is hereby explained. The composition of the designed alloy is shown in Table 1, and the composition is replaced by N-I, N-II, N-III and N-IV.

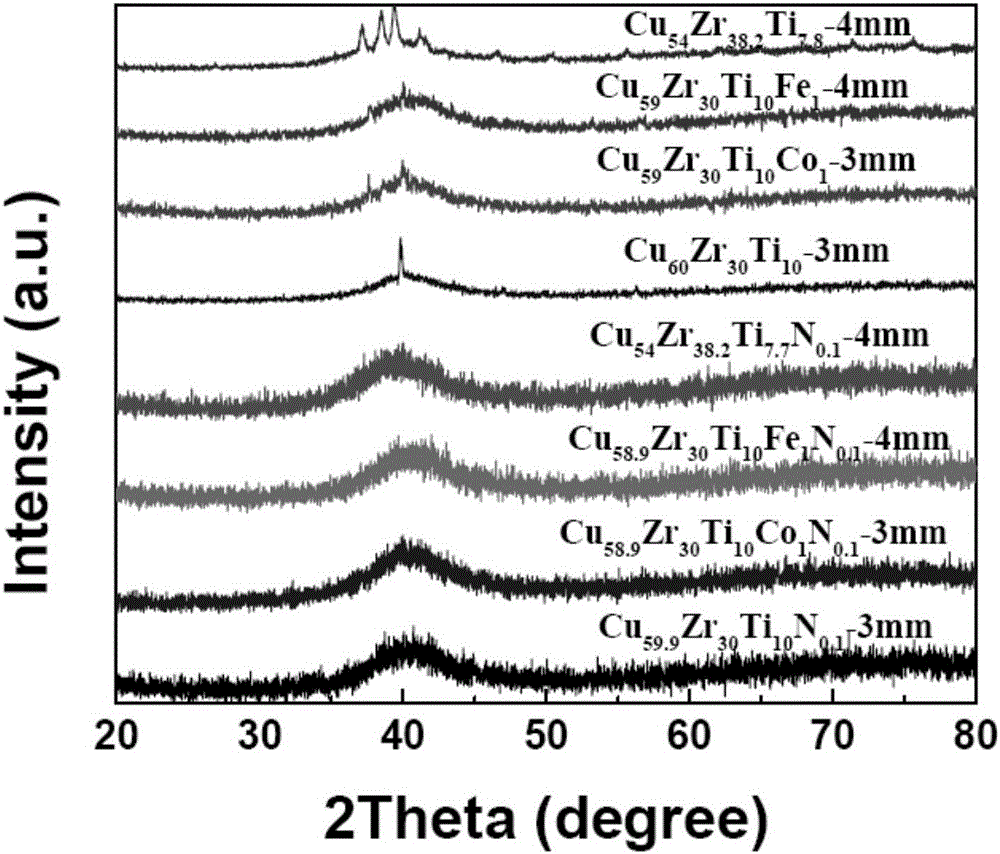

[0028] like figure 1 As shown, the XRD patterns of 3mm N-I and N-II alloys and 4mm N-III and N-IV alloys all show typical diffuse scattering amorphous peaks, and the four alloys are all amorphous phases at this size. Correspondingly, the XRD patterns of alloys that do not contain N corresponding to N-I~N-IV are as follows: figure 2 shown. It can be clearly observed that at the same size, the sharp crystal phase diffraction peaks in ...

Embodiment 2

[0032] Example 2: Preparation and properties of Zr-Hf-Cu-Fe-Al-Z-N bulk amorphous alloy

[0033] Design the Zr-Hf-Cu-Fe-Al-Z-N bulk amorphous alloy composition, and in order to reflect the influence of N microalloying on the amorphous, the inventor also prepared nitrogen-free Zr- Hf-Cu-Fe-Al-Z alloy. Zr-Hf-Cu-Fe-Al-Z is only used as a reference alloy, but it is not within the scope of this patent requirement, so it is hereby explained. The composition of the designed alloy is shown in Table 2, and the composition is replaced by N-1 to N-12.

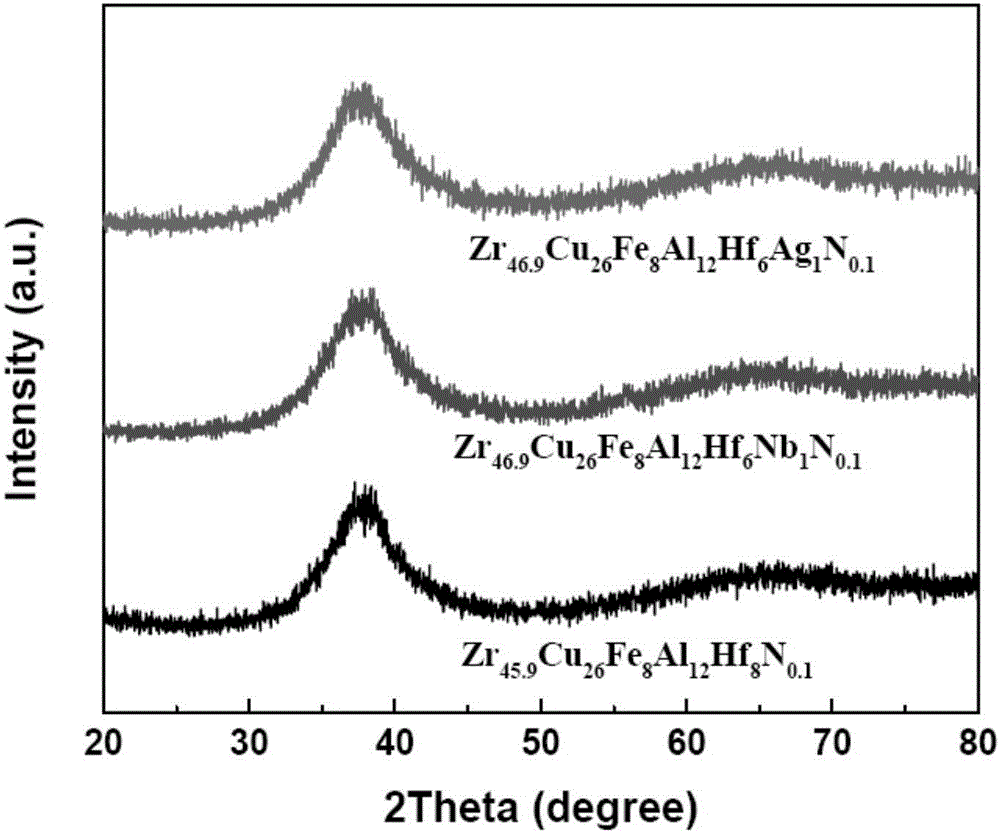

[0034] image 3 Shown are N-1, N-3, N-4 alloy 4mm sample XRD pattern. There are only diffuse scattering peaks typical of amorphous in the XRD spectrum, indicating that the 4mm alloy is in the amorphous phase, indicating that the alloy system has a strong ability to form amorphous.

[0035] Depend on Figure 4 It can be clearly observed that the addition of N element significantly enhances the Vickers hardness of the amorphous, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical dimension | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| critical dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com