High-strength aluminum-based bulk amorphous composite material

An amorphous composite material and high-strength technology, which is applied in the field of aluminum-based bulk amorphous alloy composite materials and bulk amorphous composite materials, can solve the problems of small critical forming size and poor glass forming ability, and achieve simple production process Easy to operate and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

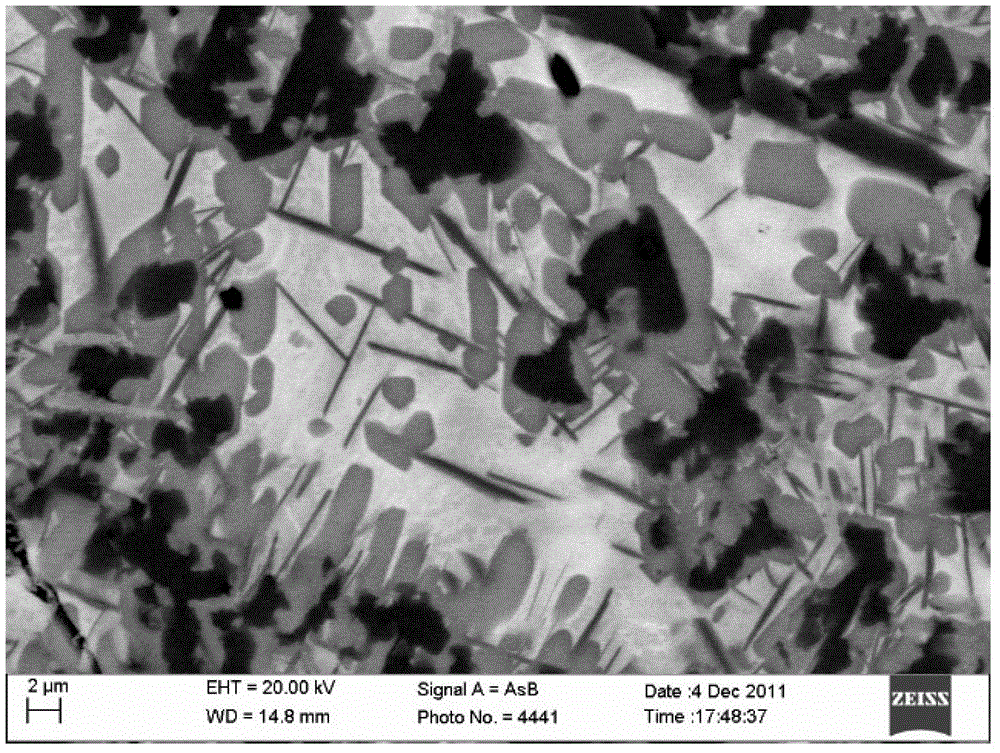

Image

Examples

Embodiment 1

[0039] Al 40 Fe 5 co 3 Cu 2 La 24 Ce 26 Preparation of Bulk Amorphous Composite Gold Materials

[0040] Step 1. Weighing various components and elements

[0041] According to alloy Al 40 Fe 5 co 3 Cu 2 La 24 Ce 26 The chemical composition and atomic percentage of each element are converted to calculate the mass fraction of each element, and they are precisely weighed on an electronic balance.

[0042] Step 2. Preparation of master alloy

[0043] Put the alloy raw material weighed in step 1 into the vacuum arc melting furnace, and evacuate to 5×10 -3 Pa, filled with argon protective gas, the argon pressure is 0.05 to 0.8 Mpa, the current is adjusted to 30-100 A, the alloy is smelted repeatedly for 4-6 times, and then Al is obtained by furnace cooling 40 Fe 5 co 3 Cu 2 La 24 Ce 26 master alloy.

[0044] Step 3. Preparation of Al 40 Fe 5 co 3 Cu 2 La 24 Ce 26 Amorphous composite alloy rod or plate

[0045] Cut an appropriate amount of master alloy accor...

Embodiment 2

[0048] Al 50 Fe 10 co 3 Cu 2 La 17 Ce 18 Preparation of Bulk Amorphous Composite Gold Materials

[0049] Step 1. Weighing various components and elements

[0050] According to alloy Al 50 Fe 10 co 3 Cu 2 La 17 Ce 18 The chemical composition and atomic percentage of each element are converted to calculate the mass fraction of each element, and they are precisely weighed on an electronic balance.

[0051] Step 2. Preparation of master alloy

[0052] Put the alloy raw material weighed in step 1 into the vacuum arc melting furnace, and evacuate to 5×10 -3 Pa, filled with argon protective gas, the argon pressure is 0.05 to 0.8 Mpa, the current is adjusted to 30-100 A, the alloy is smelted repeatedly for 4-6 times, and then Al is obtained by furnace cooling 50 Fe 10 co 3 Cu 2 La 17 Ce 18 master alloy.

[0053] Step 3. Preparation of Al 50 Fe 10 co 3 Cu 2 La 17 Ce 18 Amorphous composite alloy rod or plate

[0054] Cut an appropriate amount of master alloy a...

Embodiment 3

[0057] Al 55 Fe 15 co 3 Cu 2 La 12 Ce 13 Preparation of Bulk Amorphous Composite Gold Materials

[0058] Step 1. Weighing various components and elements

[0059] According to alloy Al 55 Fe 15 co 3 Cu 2 La 12 Ce 13 The chemical composition and atomic percentage of each element are converted to calculate the mass fraction of each element, and they are precisely weighed on an electronic balance.

[0060] Step 2. Preparation of master alloy

[0061] Put the alloy raw material weighed in step 1 into the vacuum arc melting furnace, and evacuate to 5×10 -3 Pa, filled with argon protective gas, the argon pressure is 0.05 to 0.8 Mpa, the current is adjusted to 30-100 A, the alloy is smelted repeatedly for 4-6 times, and then Al is obtained by furnace cooling 55 Fe 15 co 3 Cu 2 La 12 Ce 13 master alloy.

[0062] Step 3. Preparation of Al 55 Fe 15 co 3 Cu 2 La 12 Ce13 Amorphous composite alloy rod or plate

[0063] Cut an appropriate amount of master alloy acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com