Method for treating waste tire

A waste tire and thermal decomposition technology, applied in the preparation of liquid hydrocarbon mixtures, fibrous fillers, petroleum industry, etc., can solve the problems of a large amount of waste gas, high cost, low degree of automation, etc., and achieve automatic production process, large capacity flexibility, The effect of high oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

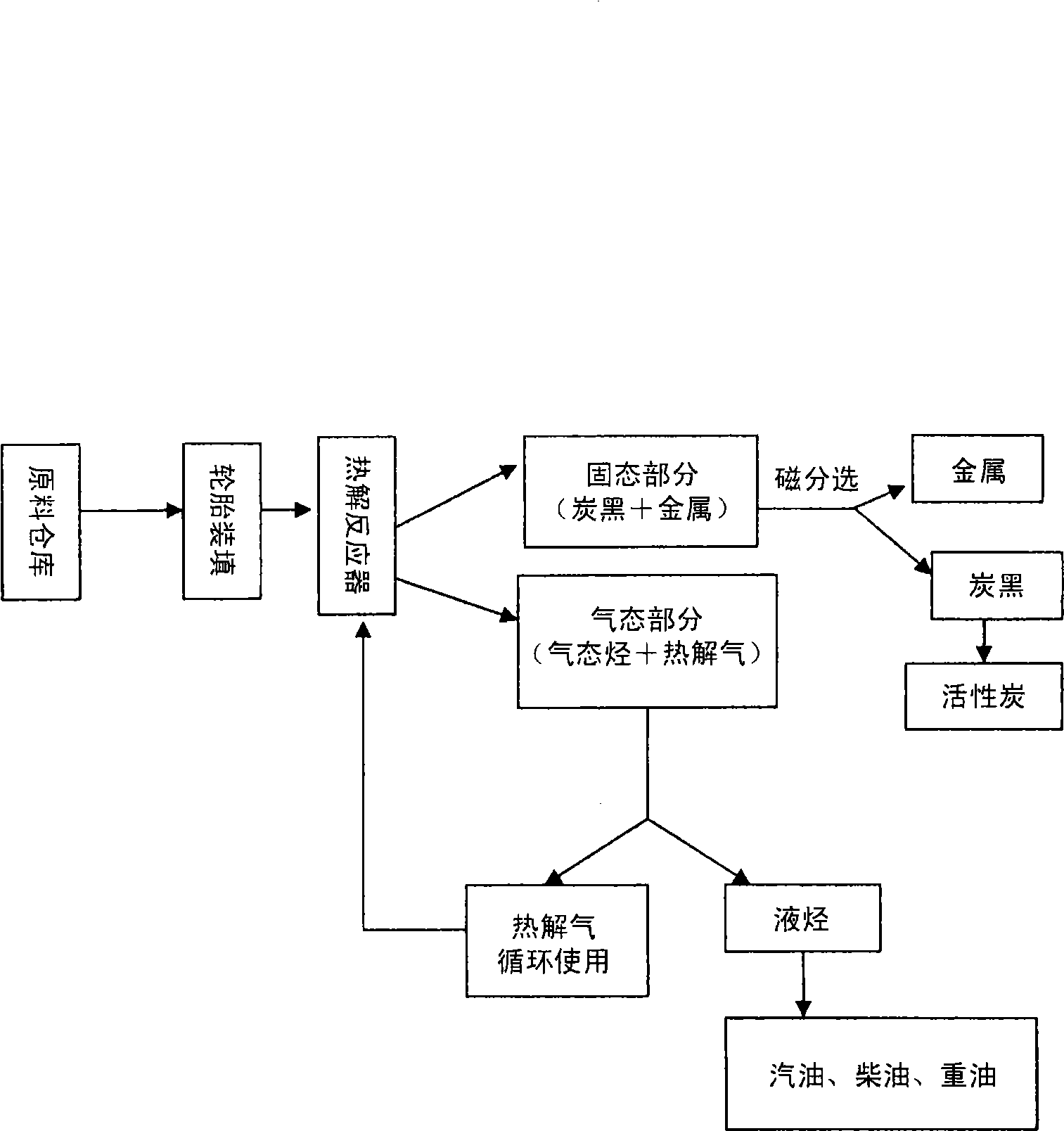

[0020] Please combine figure 1 , the treatment process of waste tires of the present invention is as follows:

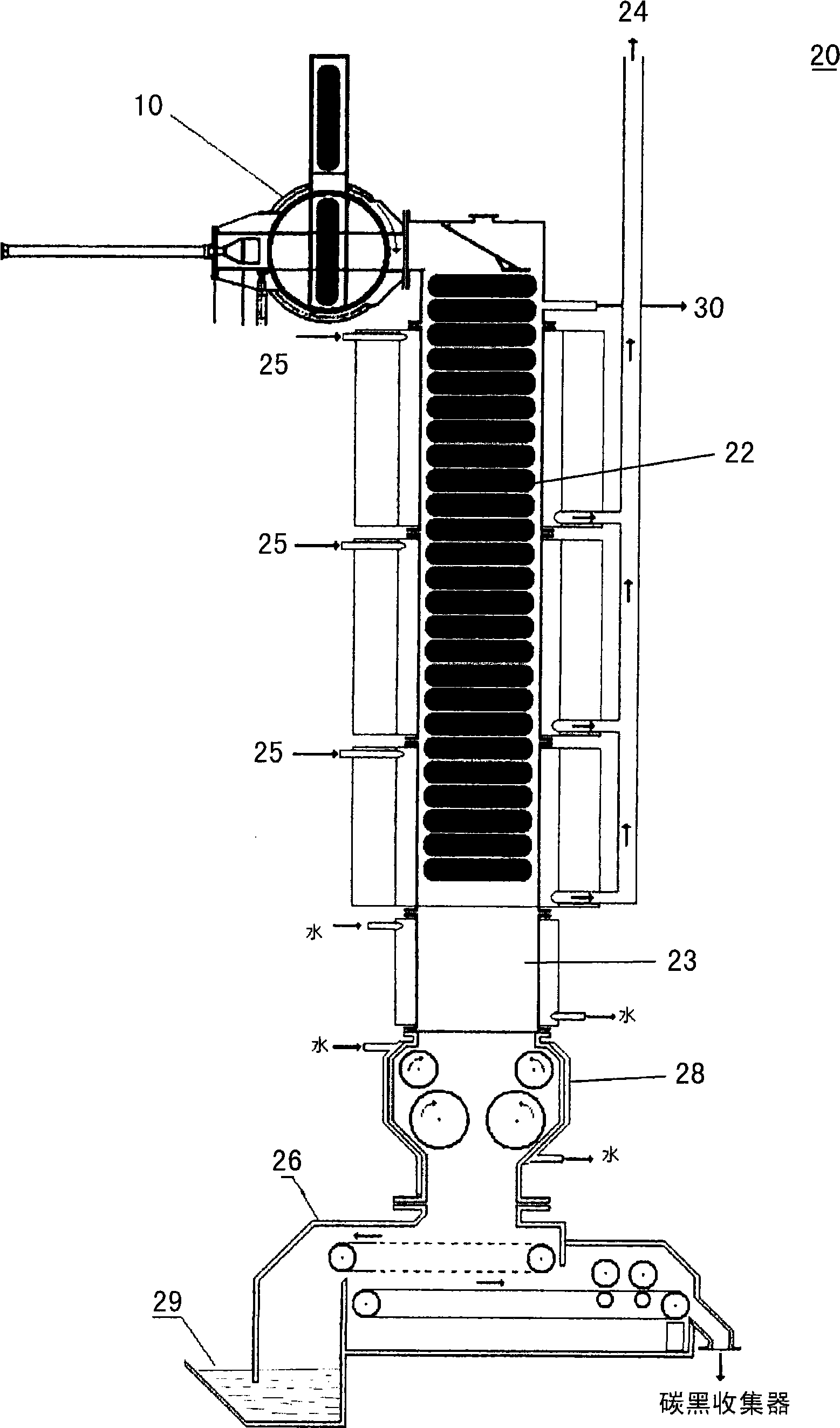

[0021] The feeding device feeds the raw material (the raw material can be the whole tire or crushed tire powder) into the sealed reactor for thermal decomposition. The thermal decomposition is divided into three temperature sections, the first section is near the feeding end, Its thermal decomposition temperature is 700-800°C, the third stage is near the discharge end, its thermal decomposition temperature is 900-1000°C, the second stage is between the feed end and the discharge end, and its thermal decomposition temperature is 800- 900°C. For ease of description, this embodiment combines figure 2 The device shown is described as an example.

[0022] The vertical reactor 20 adopted in the present invention is a furnace body with a rectangular section, with a diameter of about 1 meter and a height of about 8 meters. The lower part of the reactor is slightly wider...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com