Rotating-hoop web-roll type straightener of a straightening cutting machine and straightening method thereof

A technology of cutting machine and turning hoop, which is applied in the straightening device and straightening field of the skewed roller straightening and cutting machine of the turning hoop, which can solve the inconvenience of adjusting the angle and reduction of the straightening roller and is not suitable for large-diameter steel bars Straightening, unfavorable equipment operation and service life, etc., to achieve convenient and practical maintenance and adjustment, good straightening effect, and good straightening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

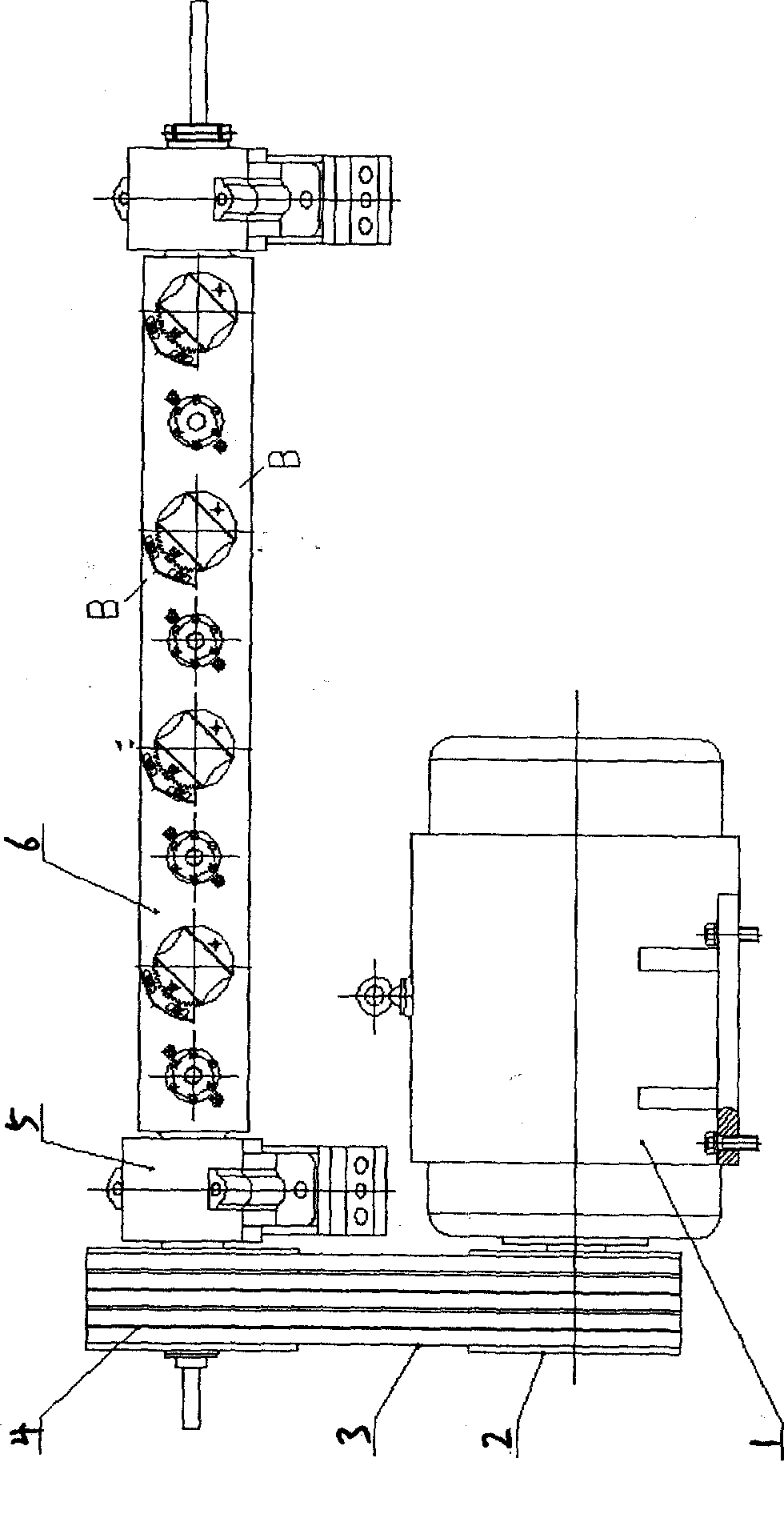

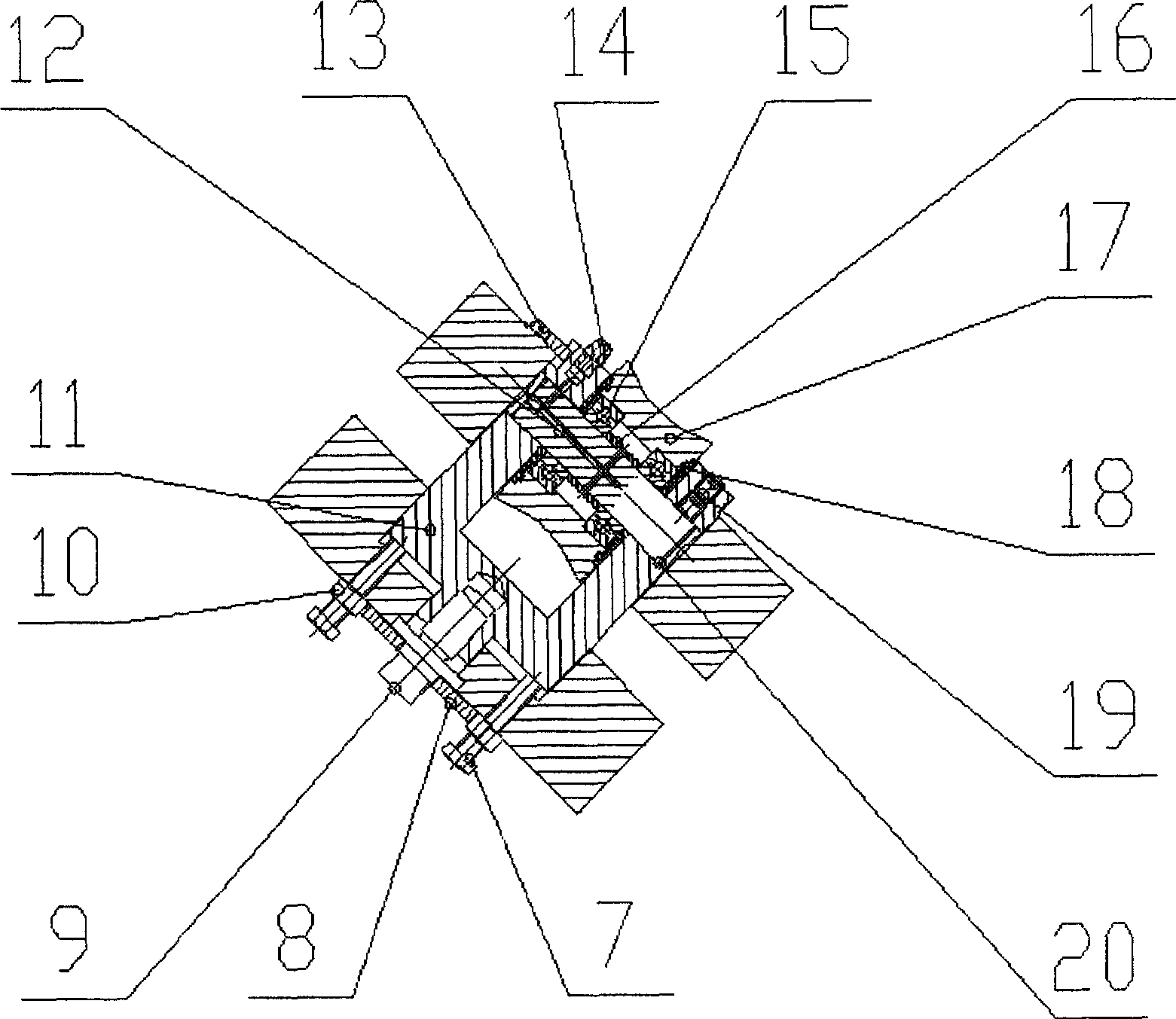

[0010] Composed of motor 1, motor pulley 2, belt 3, hoop pulley 4, bearing housing 5, hoop 6, locking bolt 7, gland 8, adjusting screw 9, locking nut 10, straightening roller frame 11 , shaft 12, gear plate 13, grease nipple 14, bearing 15, sleeve 16, straightening roller 17, cover 18, set screw 19, retaining ring 20;

Embodiment 2

[0012] The motor pulley 2 is set on one side of the motor 1, the hoop pulley 4 is set above the motor pulley 2, the belt 3 is set on the outer circumference of the motor pulley 2 and the hoop pulley 4, and the bearing seat 5 is set on the hoop pulley On one side of 4, bearing housings 5 are arranged at both ends of the swivel hoop 6; at least one mounting hole is arranged horizontally in the middle of the swivel hoop 6, and at least one observation window is set in the middle of the side; a straightening roller assembly is arranged in the mounting hole.

Embodiment 3

[0014] A roller frame 11 is set in the installation hole of the straightening roller assembly, an adjusting screw 9 is arranged in the middle of one side of the hoop 6, and the adjusting screw 9 passes through the middle of the hoop 6 and is set in the roller frame 11, and the gland 8 is set on the hoop 6 The outer side of fixed adjustment screw mandrel 9; adjustment screw mandrel 9 both sides are provided with locking bolt 7 and are arranged on roller frame 11 both sides through swivel hoop 6, and lock nut 10 is arranged on swivel hoop 6 outsides and fixes locking bolt 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com