High energy electronic ignition system for high pressure gas well

A high-energy electronic and ignition system technology, which is applied in the petrochemical field, can solve the problems such as the water spraying out of the ignition, and achieve the effect of no safety hazard, easy to extinguish, and high discharge power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

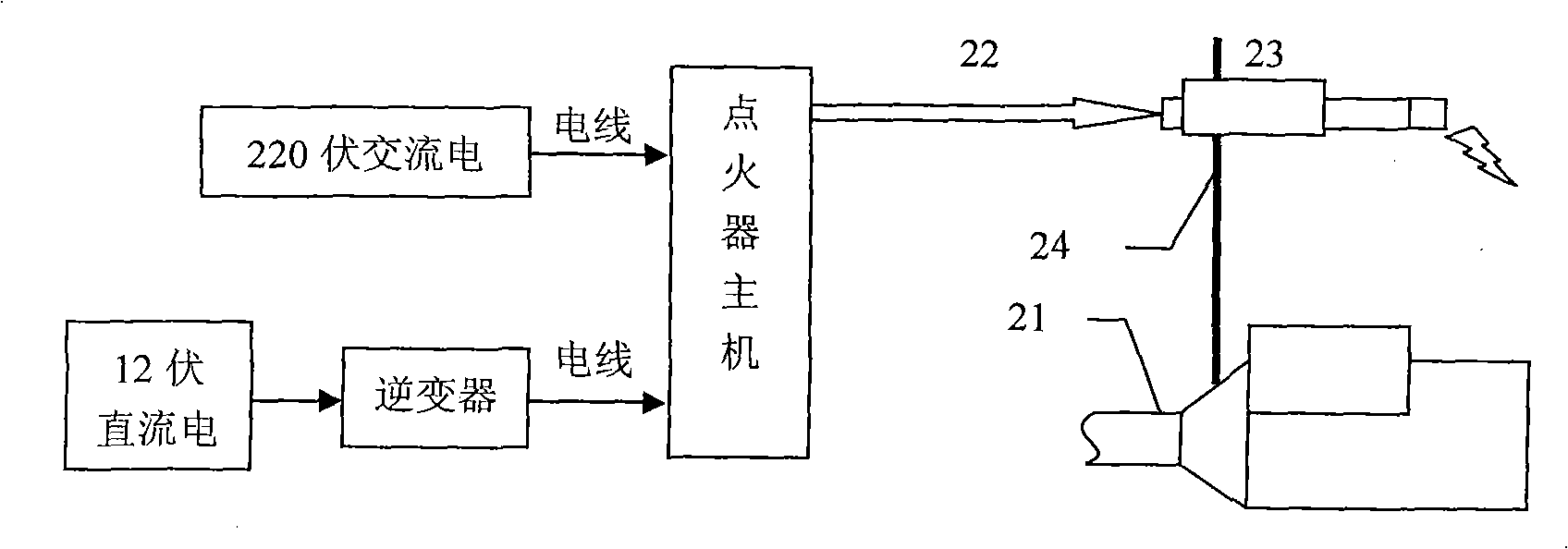

[0032] Refer to the attached figure 1 , the invention discloses a high-energy electronic ignition system for high-pressure natural gas wells, including an input power supply and a blowout device 21, the input power supply is connected to the main engine of the igniter, and the main engine of the igniter is connected to the ignition rod 23 through a fire-resistant cable 22, and the ignition rod 23 Be fixed on the top of the spraying device 21 through the ignition rod support 24, and the spraying device is a common spraying device in the prior art, and is made of parts such as spray barrels.

Embodiment 2

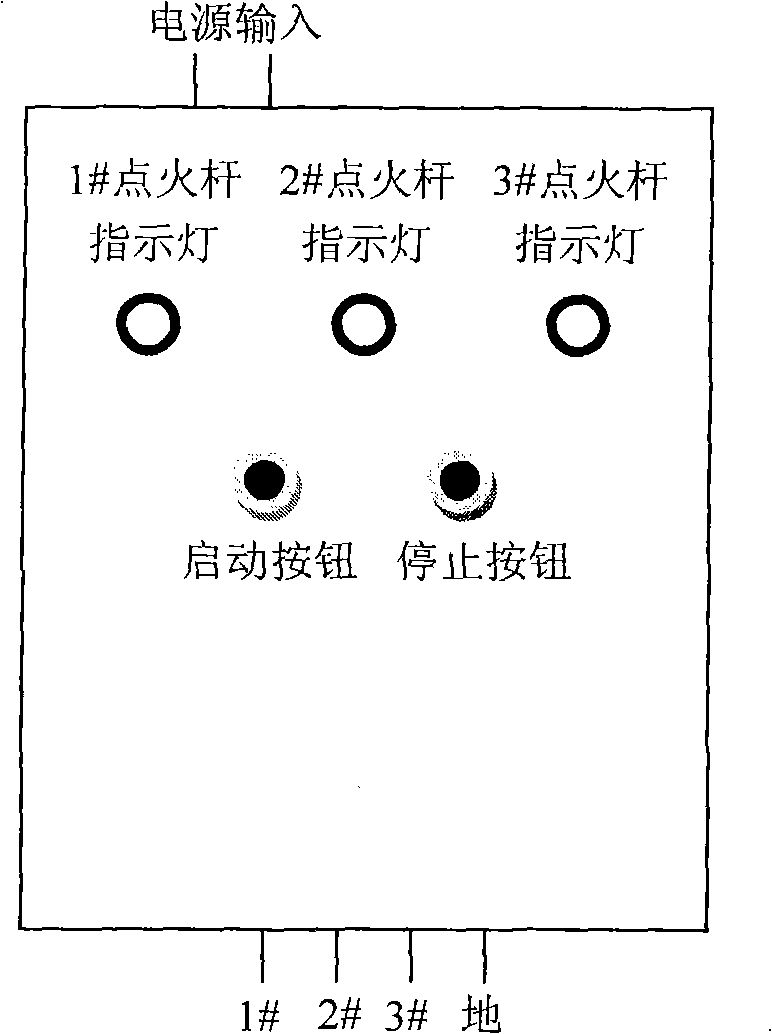

[0034] Refer to the attached image 3 Another embodiment of the present invention is that, on the basis of Example 1, the ignition host includes sequentially connected transformer circuit parts for converting the input power into 2000V high-voltage electricity, and a circuit for charging the input high-voltage electricity. An energy storage circuit portion and a discharge circuit portion that controls the release of stored electrical energy. The transformer circuit part includes an inverter for converting 12V direct current into 220V alternating current and a transformer for converting 220V alternating current into 2000V high voltage. The energy storage circuit part includes a diode, a capacitor, a resistor, a triac and an inductor, wherein the diode part is used to rectify the input 2000V high-voltage alternating current, and after passing through the current limiting resistor, the triac and the inductor control the circuit. Capacitor charging and discharging. The discharge...

Embodiment 3

[0036] Refer to the attached figure 1 , Another embodiment of the present invention is that on the basis of Example 1, the input power supply is two types, one is 220V AC, and the other is 12V DC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com