Waste Crumb rubber modified asphalt and preparation method thereof

A technology of waste rubber powder and modified asphalt, which is applied to building components, building insulation materials, buildings, etc., can solve the problems of difficult mixing operation, affecting the performance of modified asphalt, and poor dispersion, so as to save energy consumption and improve phase efficiency. Capacitive, high dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Use 100 parts by mass of base asphalt, 10 parts of 40-mesh waste rubber powder, and 3 parts of carboxylated nitrile rubber modifier. Mix evenly with an ordinary mixer at 150-170 ° C for about 15 minutes, and then use twin-screw extrusion Exit the machine for high-shear dispersion at a speed of 50 rad / min to obtain modified asphalt, and test the performance indicators of the modified asphalt. The results are shown in Table 2.

[0032] The equipment used is a twin-screw extruder with an aspect ratio of 50 and a diameter of 35 cm. From the feed inlet to the machine head, the temperature of the screw gradually increases and then decreases, and is between 150°C and 170°C.

Embodiment 2

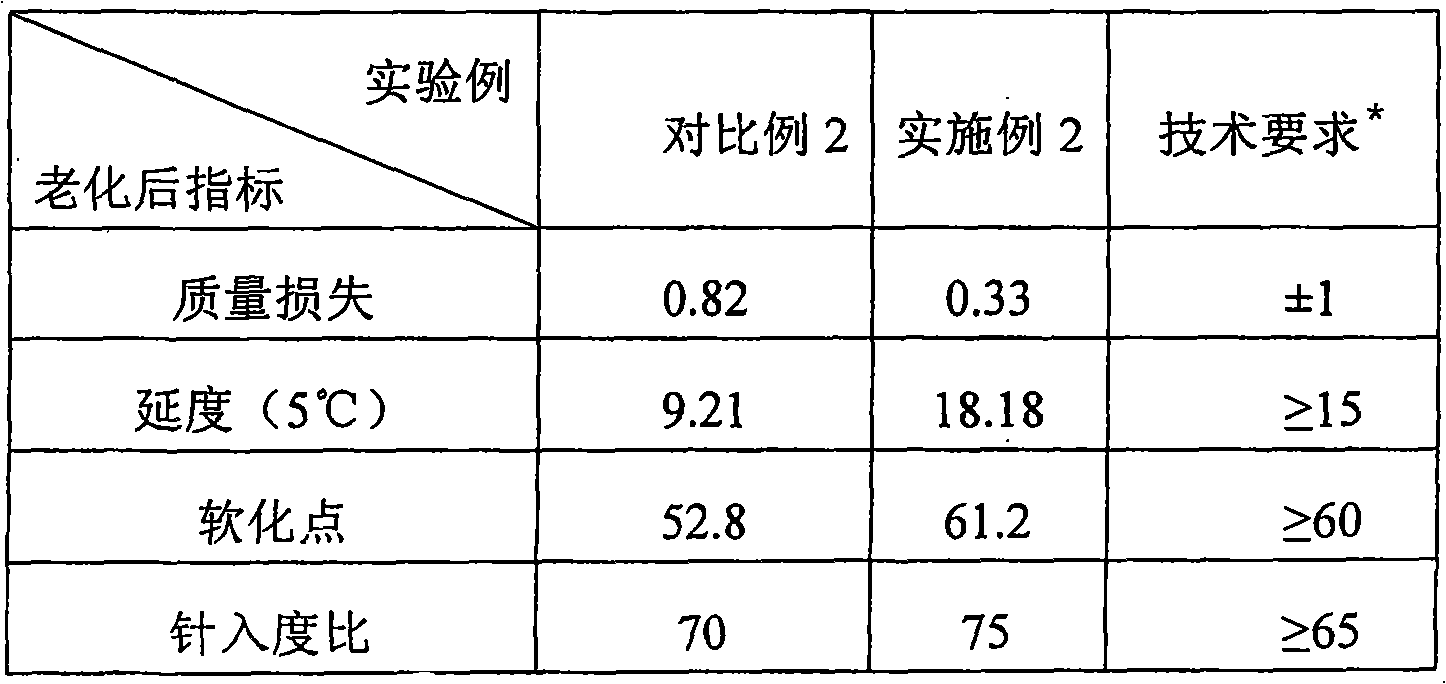

[0034] Use 100 parts by mass of base asphalt, 15 parts of 80-mesh waste rubber powder, and 4 parts of ethylene-vinyl acetate copolymer modifier. Mix them uniformly with an ordinary mixer at 150-170 ° C for about 15 minutes, and then use The internal mixer is used for high-shear dispersion, and the mixing time is 5-10 minutes to obtain the modified asphalt, and the performance index of the modified asphalt is tested. The results are shown in Table 2, and then the aging performance is measured, and the results are shown in Table 3.

[0035] The technical parameters of the internal mixer used are: the capacity is 100 liters, the rotating speed is 80 rpm, and the temperature is controlled at 150-170°C.

Embodiment 3

[0037] Use 100 parts by mass of base asphalt, 20 parts of 120-mesh waste rubber powder, and 5 parts of modifier polyethylene. Mix evenly with an ordinary mixer at 150-170°C for about 15 minutes, and then use an internal mixer for high-shear Cut and disperse, and the mixing time is 5-10 minutes to obtain the modified asphalt, and test the performance index of the modified asphalt. The results are shown in Table 2.

[0038] The technical parameters of the internal mixer used are: the capacity is 100 liters, the rotating speed is 80 rpm, and the temperature is controlled at 150-170°C.

[0039] Table 2 Gained modified asphalt performance data of the present invention

[0040] Test indicators

unit

skills requirement *

Example 1

Example 2

Example 3

Penetration

0.1mm

40-60

58.9

57.6

58.7

5°C Ductility

cm

>20

20.05

22.85

20.60

Softening Point

℃

>60

60.2

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com