Safe blood or blood component storage container and preparation method thereof

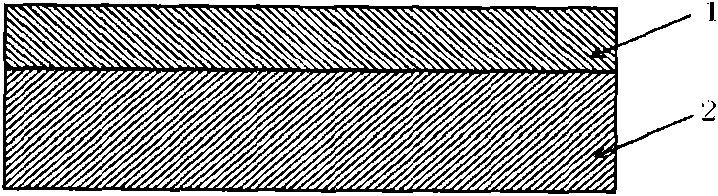

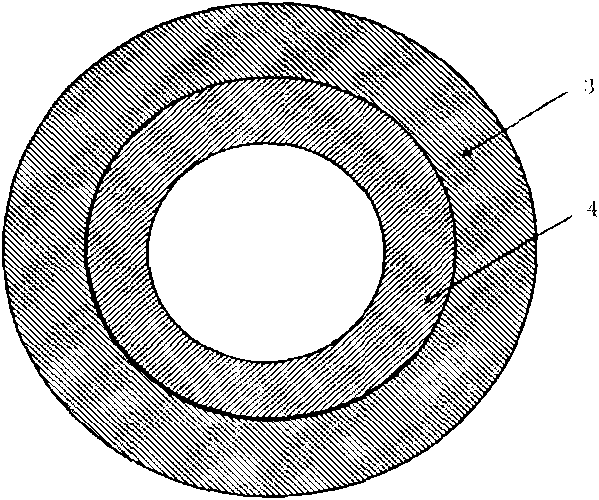

A blood component and storage container technology, applied in the field of medical devices, can solve the problems of easy damage, leakage, high production cost of storage containers, high material cost, etc., and achieve reduced adsorption and coagulation, excellent blood compatibility, and mechanical properties excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

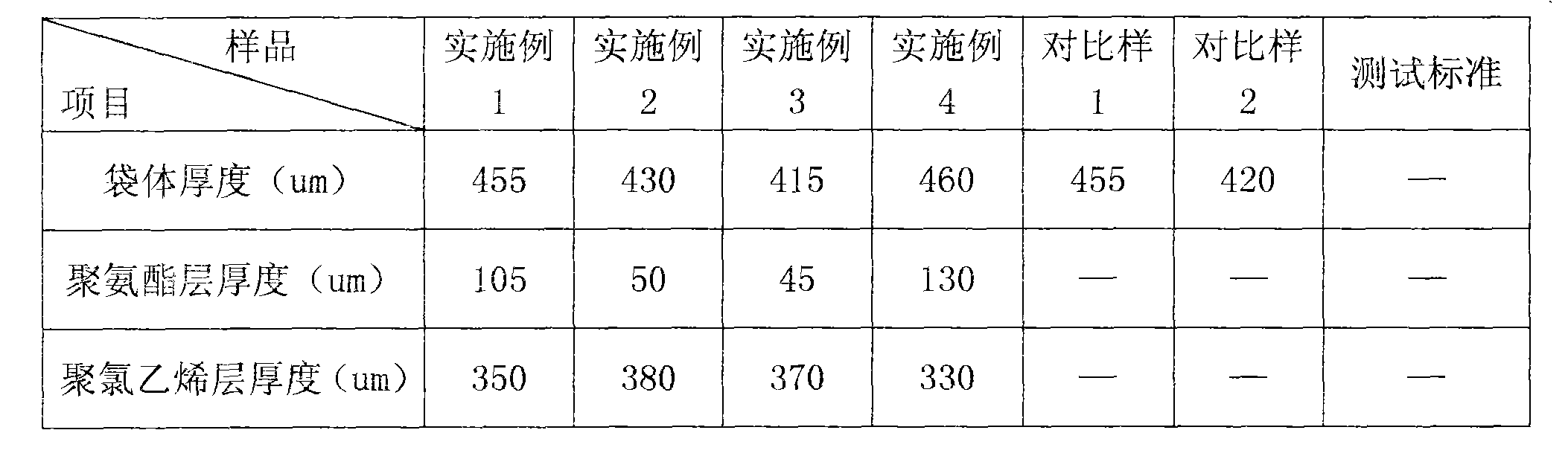

Embodiment 1

[0037] Weigh A1 and B1 materials and add them to the double-layer co-extrusion blow molding unit respectively. The screw diameter of the extruder unit is 40mm, the length-to-diameter ratio is 36, and the head is the center feed of the inner layer and the side feed of the outer layer for co-extrusion. Blow-molded structure. Set the temperature of the feed section of the extruder for material A1 to 150-160°C, the temperature of the compression section to 160-170°C, and the temperature of the metering section to 170-185°C; set the temperature of the feed section of the extruder for material B1 to 140-155°C, The temperature of the compression section is 150-165°C, the temperature of the metering section is 160-175°C; the temperature of the double-layer co-extrusion blow molding head is set at 170-180°C. After drying the polyurethane and polyvinyl chloride with a weight ratio of 1:4, add them to the hopper of the polyurethane extruder and the hopper of the polyvinyl chloride extrud...

Embodiment 2

[0041] Weigh A1 and B2 materials and add them to the double-layer co-extrusion blow molding unit respectively. The screw diameter of the extrusion unit is 40mm, and the length-to-diameter ratio is 36. plastic structure. Set the temperature of the feed section of the extruder for material A1 to 150-160°C, the temperature of the compression section to 160-170°C, and the temperature of the metering section to 170-185°C; set the temperature of the feed section of the extruder for material B2 to 140-155°C, The temperature of the compression section is 150-165°C, the temperature of the metering section is 160-175°C; the temperature of the double-layer co-extrusion blow molding head is set at 170-180°C. After drying the polyurethane and polyvinyl chloride with a weight ratio of 1:7, add them to the hopper of the polyurethane extruder and the hopper of the polyvinyl chloride extruder of the double-layer co-extrusion blow molding unit, start the machine, and set the polyurethane extrud...

Embodiment 3

[0045] Weigh the A2 and B1 materials and add them to the double-layer co-extrusion blow molding unit respectively. The screw diameter of the extruder unit is 40mm, the length-to-diameter ratio is 36, and the head is the center feed of the inner layer and the side feed of the outer layer for co-extrusion. Blow-molded structure. Set the temperature of the feed section of the extruder for material A2 to 150-160°C, the temperature of the compression section to 160-170°C, and the temperature of the metering section to 170-185°C; set the temperature of the feed section of the extruder for material B1 to 140-155°C, The temperature of the compression section is 150-165°C, the temperature of the metering section is 160-175°C; the temperature of the double-layer co-extrusion blow molding head is set at 170-180°C. After drying the polyurethane and polyvinyl chloride with a weight ratio of 1:7, add them to the hopper of the polyurethane extruder and the hopper of the polyvinyl chloride ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com