Method for preparing silicon-based anode material of lithium-ion battery

A technology for lithium-ion batteries and composite materials, applied in the field of preparation of silicon-based negative electrode composite materials for lithium-ion batteries, can solve problems affecting electrode cycle stability, achieve good electrochemical performance, low raw material cost, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

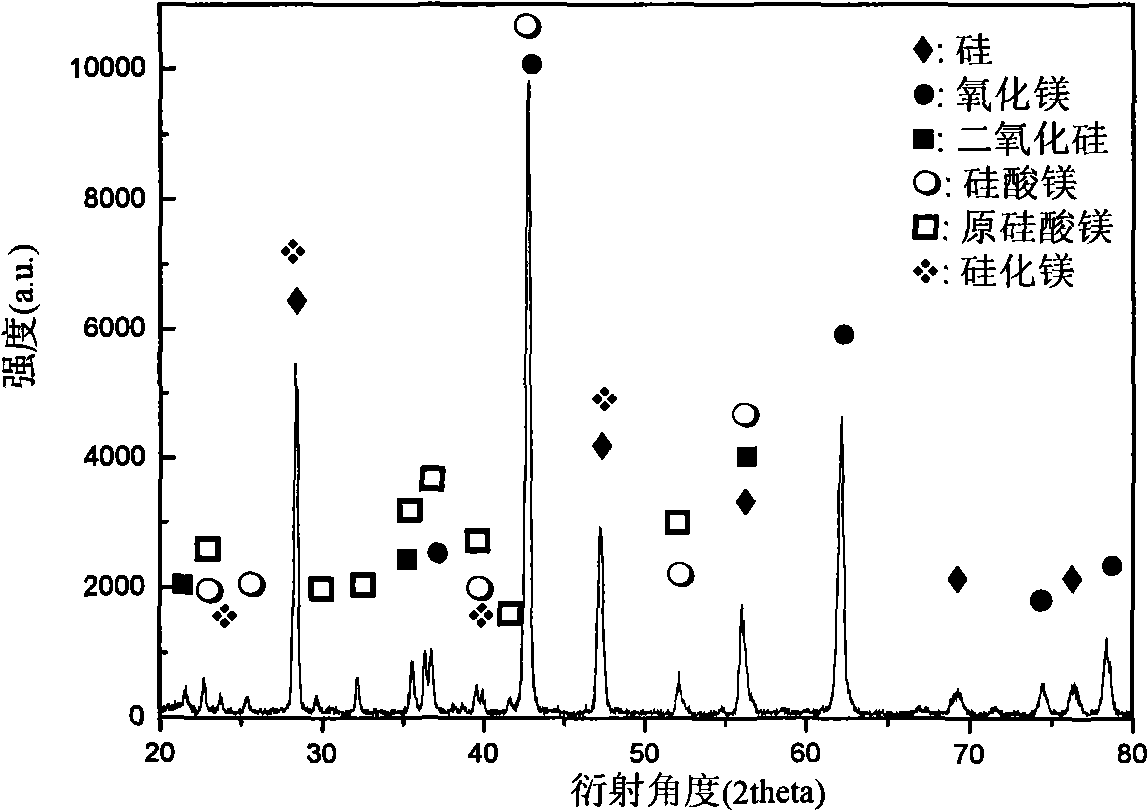

[0017] SiO 2 (≥98.5%) and Mg (>99.0%) are the initial raw materials, and the molar ratio is 1:2. 700°C, keep warm for 2 hours, then turn off the power, and cool down to room temperature naturally. The XRD phase analysis result ( figure 1 shown) shows that the synthesized products are Si, MgO and a small amount of Mg 2 Si and MgSiO 3 , Mg 2 SiO 4 , without the presence of other oxide impurity phases.

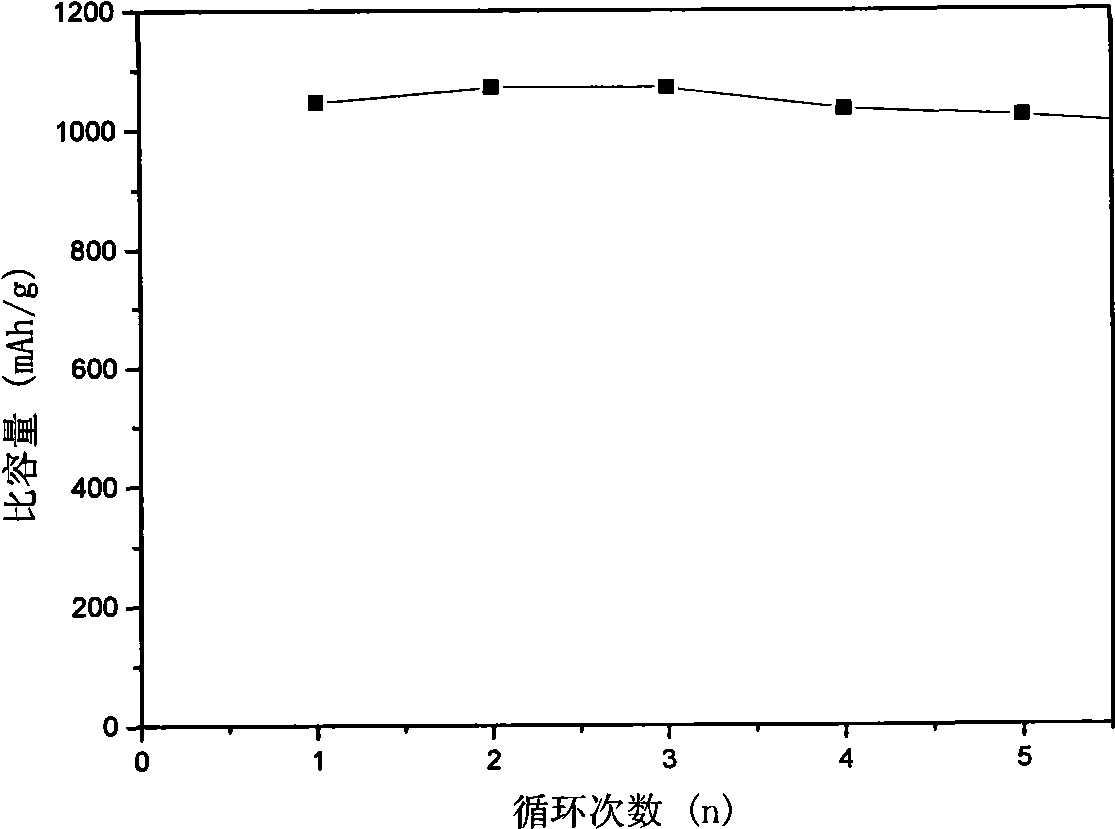

[0018] Mix the synthetic product, the conductive agent acetylene black, and the binder PVDF at a mass ratio of 75:15:15, add an appropriate amount of NMP to make a slurry, apply it evenly on the copper foil, and cut it into a circular pole piece after drying. The experimental battery composed of metal lithium was subjected to constant current charge and discharge experiments. The charge and discharge current was 100mA / g, and the charge and discharge voltage range was controlled between 0.01-1.5V. The first discharge specific capacity of the prepared Si / MgO composite negati...

Embodiment 2

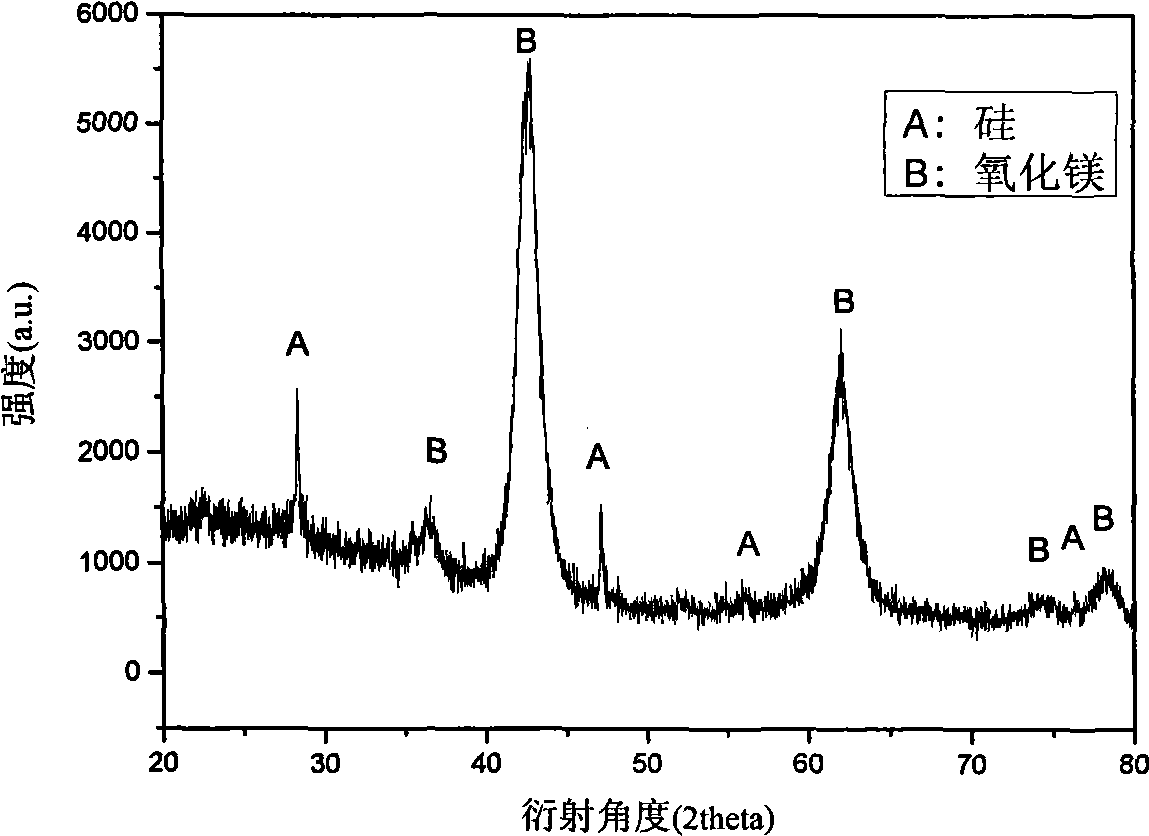

[0020] SiO 2 (≥98.5%) and Mg (>99.0%) are the initial raw materials, and the molar ratio is 1:2 for batching, the mixture is put into a ball milling tank, the mass ratio of balls to the mixture is 20:1, and high-energy ball milling is carried out under an inert atmosphere 2 hours at 500 rpm. The XRD phase analysis result ( figure 2 Shown) shows that the synthesized products are mainly Si, MgO.

[0021] Mix the synthetic product, the conductive agent acetylene black, and the binder PVDF at a mass ratio of 75:15:15, add an appropriate amount of NMP to make a slurry, apply it evenly on the copper foil, and cut it into a circular pole piece after drying. The experimental battery composed of metal lithium was subjected to constant current charge and discharge experiments. The charge and discharge current was 100mA / g, and the charge and discharge voltage range was controlled between 0.01-1.5V. The first discharge specific capacity of the prepared Si / MgO composite negative electr...

Embodiment 3

[0023] SiO 2 (≥98.5%) and Mg (>99.0%) are the initial raw materials, and the molar ratio is 1:2. 650°C, keep warm for 4 hours, then turn off the power, and cool down to room temperature naturally.

[0024] Mix the synthetic product, the conductive agent acetylene black, and the binder PVDF at a mass ratio of 75:15:15, add an appropriate amount of NMP to make a slurry, apply it evenly on the copper foil, and cut it into a circular pole piece after drying. The experimental battery composed of metal lithium was subjected to constant current charge and discharge experiments. The charge and discharge current was 100mA / g, and the charge and discharge voltage range was controlled between 0.01-1.5V. The first discharge specific capacity of the prepared Si / MgO composite negative electrode material is about 1290mAh / g, and the first charge specific capacity is 980mAh / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com