Aluminum electrolytic capacitor anode foil secondary corrosion liquid formula

A secondary corrosion technology for aluminum electrolytic capacitors, applied in electrolytic capacitors, capacitors, circuits, etc., can solve the problems of high solubility on the surface of aluminum foil, and achieve the effects of improving bending strength, capacity, and electrostatic capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

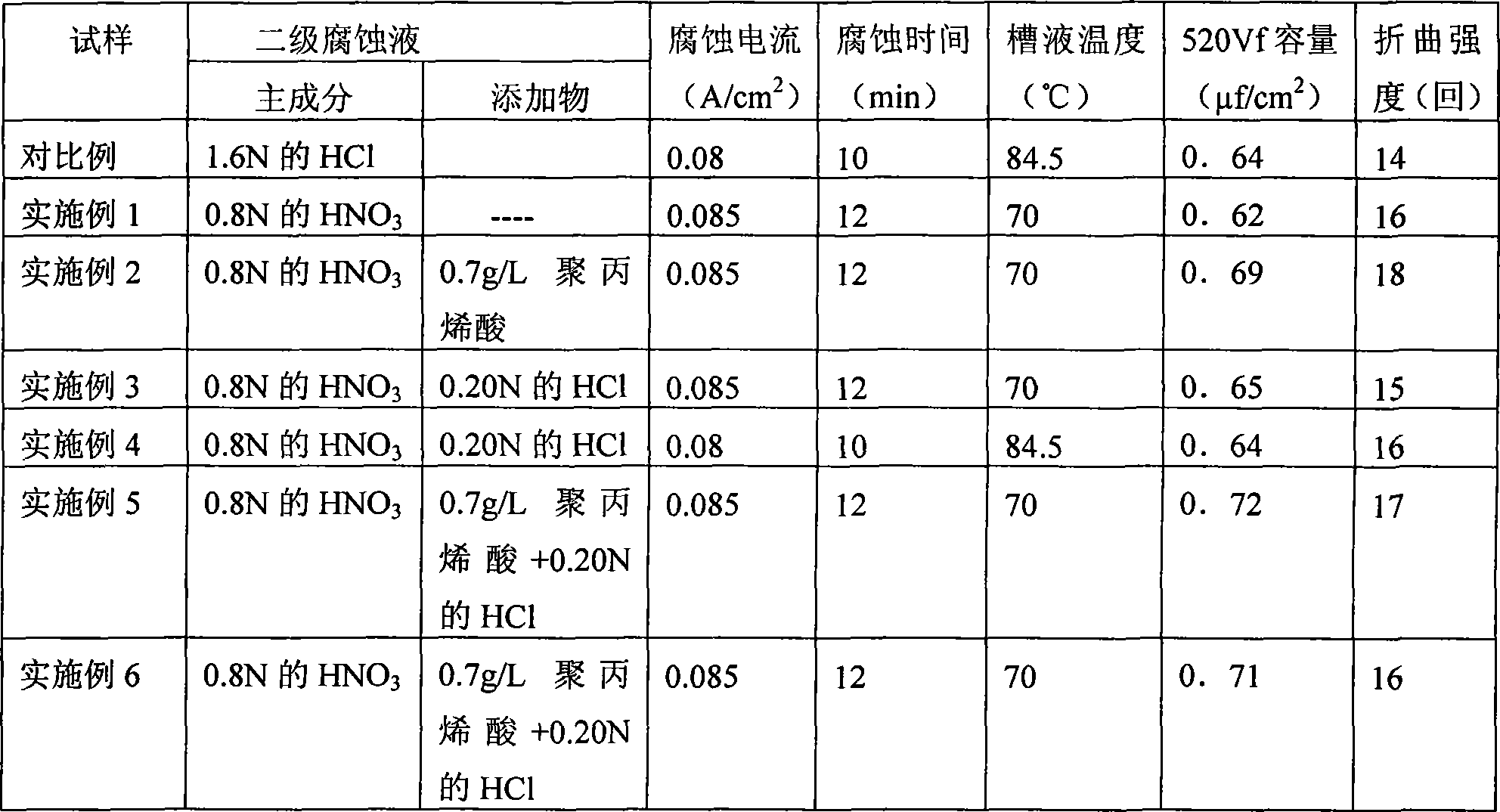

[0017] A formula of secondary corrosion solution using nitric acid as the anode foil of aluminum electrolytic capacitor, which is to put the aluminum foil after pretreatment and primary corrosion into 70.0℃, 0.8N HNO 3 In the solution, the applied current density is 0.085A / cm 2 Perform secondary corrosion for 12 minutes, and then perform normal post-justification. The 520Vf capacity and bending strength of the aluminum foil are shown in Table 1.

Embodiment 2

[0019] A formula based on nitric acid and adding a small amount of polyacrylic acid anion electrolyte is to put the aluminum foil after pretreatment and primary corrosion into 70.0℃, 0.8N HNO 3 In the mixed solution with 0.7g / L polyacrylic acid, the applied current density is 0.085A / cm 2 Perform secondary corrosion for 12 minutes, and then perform normal post-justification. The 520Vf capacity and bending strength of the aluminum foil are shown in Table 1.

Embodiment 3

[0021] A formula that uses nitric acid as the main raw material and adds a small amount of compounds containing chloride ions. It is to put the aluminum foil after pretreatment and primary corrosion into 70.0°C, 0.8N HNO 3 In the mixed solution with 0.2N HCl, the applied current density is 0.085A / cm 2 Perform secondary corrosion for 12 minutes, and then perform normal post-justification. The 520Vf capacity and bending strength of the aluminum foil are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com