Hole reaming equipment and construction method of multi-branch anchorage system

A construction method and an anchoring technology, which is applied in the fields of drilling equipment, earthwork drilling, infrastructure engineering, etc., can solve problems such as unsatisfactory reaming effect, oil pipes occupying the anchor hole space, and anchoring bodies that cannot form multi-branch discs, etc., to achieve Avoid passing through unfavorable formations, improve construction conditions, and reduce the effect of over-redline problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

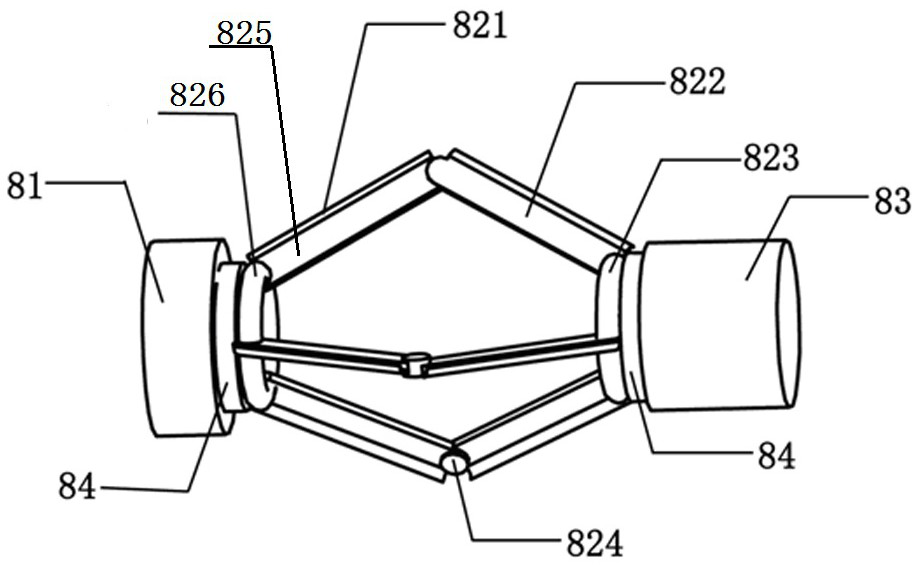

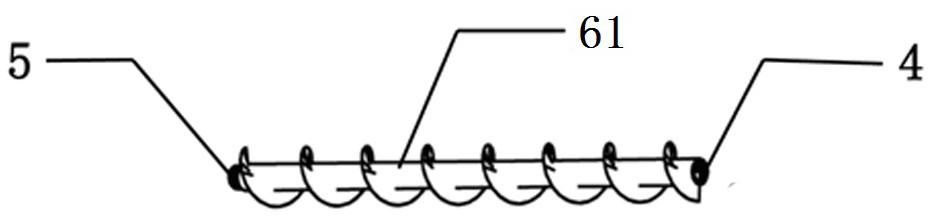

[0033] Such as Figure 1~4 As shown, a multi-branch anchoring system reaming equipment includes a fixing plate 2 for fixing at the anchor hole 9 of the soil body, and the fixing plate 2 is connected with a hollow pipe 1 for extending into the anchor hole, and the fixed The rear side of the plate 2 is connected with a motor 7 through a hydraulic cylinder 3, the main shaft of the motor 7 is connected with a spiral soil removal rod 6 passing through the hollow pipe 1, and the front end of the spiral soil removal rod 6 protrudes from the front end of the hollow pipe. The front end of the pipe 1 is provided with a reaming head 8 which is driven to rotate by the spiral soil removal rod 6 and controlled to expand and contract by the axial movement of the spiral soil removal rod 6 . The hole reaming equipment of the present invention drives the spiral soil removal rod 6 to move axially through the hydraulic cylinder, and then realizes the expansion and contraction of the reaming head....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com