Method for preparing light concrete by municipal solid waste incineration fly ash

A technology for domestic waste incineration and light concrete, which is applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of high alkalinity, process difficulty, and high processing temperature, and achieve good macro performance and simple process. , the effect of meeting safety requirements

Inactive Publication Date: 2012-01-04

SHANGHAI INST OF TECH

View PDF2 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, due to the limitation of its own performance, the vitrified body cannot be directly used as a building material. It is often used as a batch of cement or as an aggregate in concrete; alkali corrosion

On the basis of vitrification, Song Yu used fly ash-based raw materials to make glass-ceramics with better performance, but the processing temperature was as high as 1,500°C, which made the process quite difficult.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0023] 1. Raw materials

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

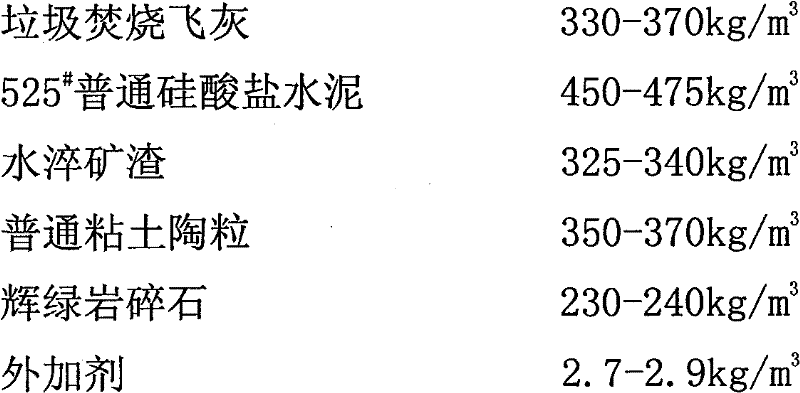

The invention discloses a method for preparing light concrete by municipal solid waste incineration fly ash. The light concrete comprises the following compositions according to material ratio: 330 to 370kg / m<3> of the municipal solid waste incineration fly ash, 450 to 475kg / m<3> of 525# common Portland cement, 325 to 340kg / m<3> of water-granulated slag, 350 to 370kg / m<3> of ordinary clay porcelain granules, 230 to 240kg / m<3> of diabase slag, and 2.7 to 2.9kg / m<3> of admixture. The method uses the municipal solid waste incineration fly ash to prepare the light concrete, can solidify heavy metal in fly ash, thereby achieving the aim of innocent treatment of the municipal solid waste incineration fly ash. The method has a simple process, and the obtained finished product has strength grade of CL40 and apparent density of 1800, and has good macroscopic performance.

Description

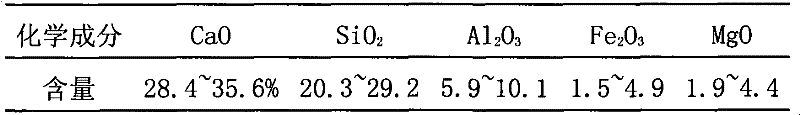

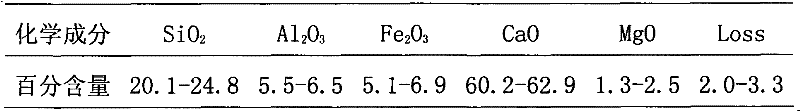

technical field [0001] The invention relates to a waste utilization method of household garbage, in particular to a method for preparing light concrete by using household garbage incineration fly ash. Background technique [0002] Domestic waste incineration fly ash is a recognized hazardous waste, which concentrates a large amount of heavy metals and also contains a small amount of highly toxic dioxin-like organic substances. my country's GWKB3-2000 clearly stipulates that fly ash is a hazardous waste that must be treated in a harmless manner. treatment. Domestic waste incineration fly ash is another resource. Fly ash contains more silicates and aluminates, which can be used as admixtures for building materials; fly ash also contains more vitreous and many active network activation Metal ions and fly ash also have a certain activity; in addition, fly ash has a particle size composition of about 200 meshes, which also increases the activity of fly ash and can save energy in ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C04B28/04C04B14/02C04B18/06C04B14/10

CPCC04B28/04C04B2111/40Y02W30/91C04B14/02C04B14/12C04B18/0418C04B18/106C04B22/124C04B24/122C04B24/226C04B18/12C04B18/141

Inventor 张海英赵由才祁景玉许实

Owner SHANGHAI INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com