Preparation method for laminated photo-anode film of dye-sensitized solar cell

A technology of solar cells and dye sensitization, applied in the research field of nanocrystalline films of dye-sensitized solar cells, to achieve the effect of tight bonding and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

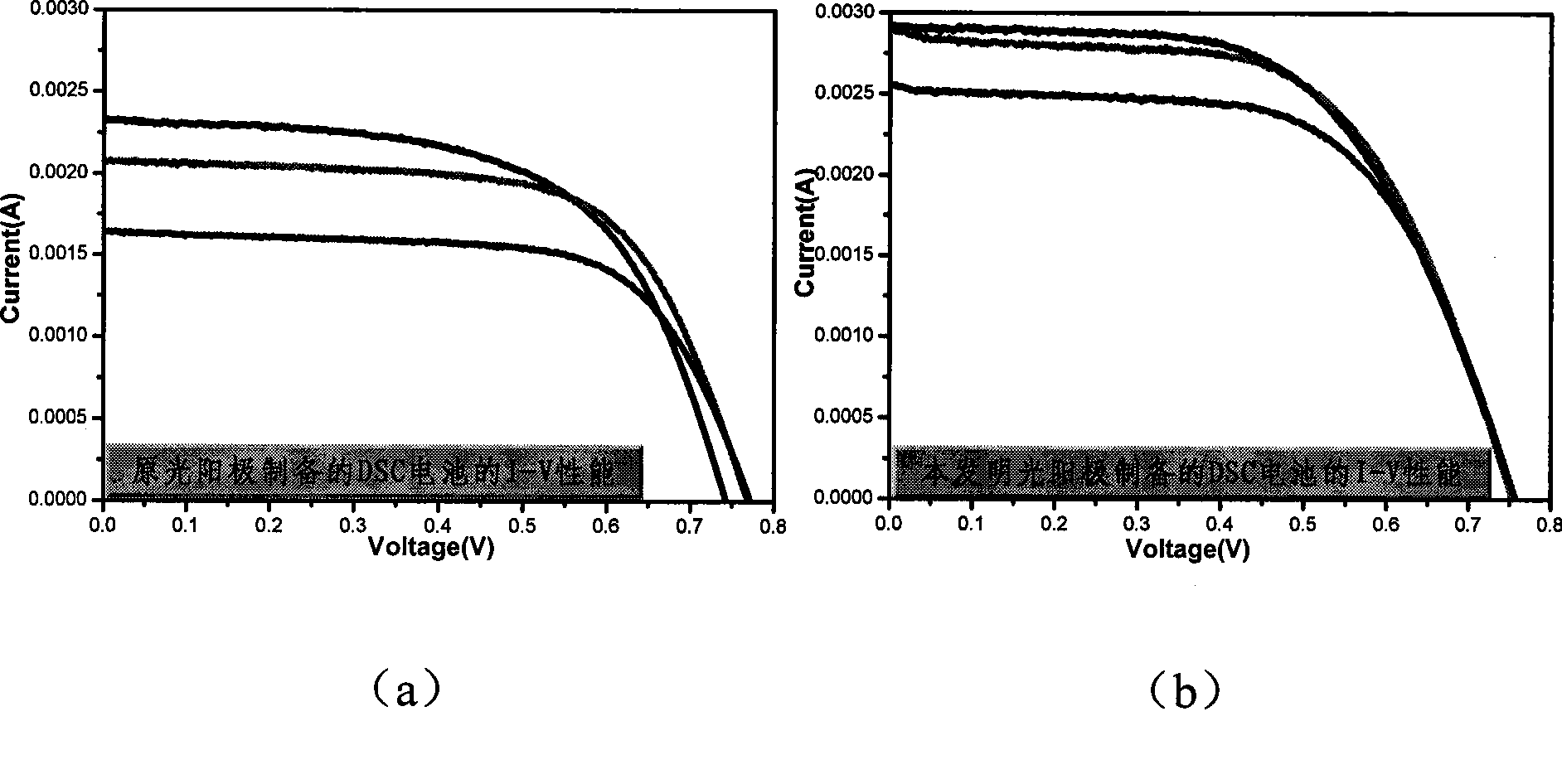

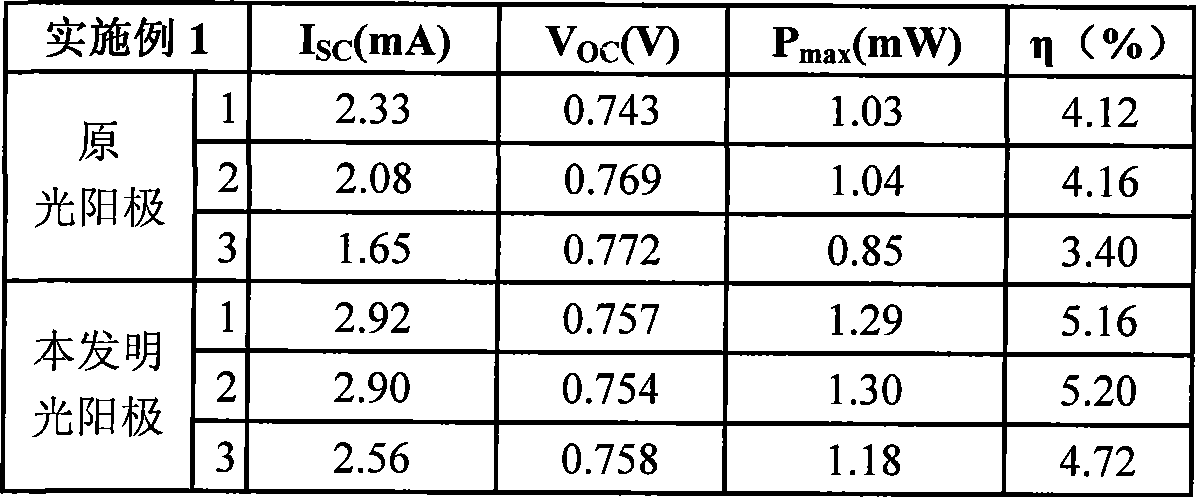

Embodiment 1

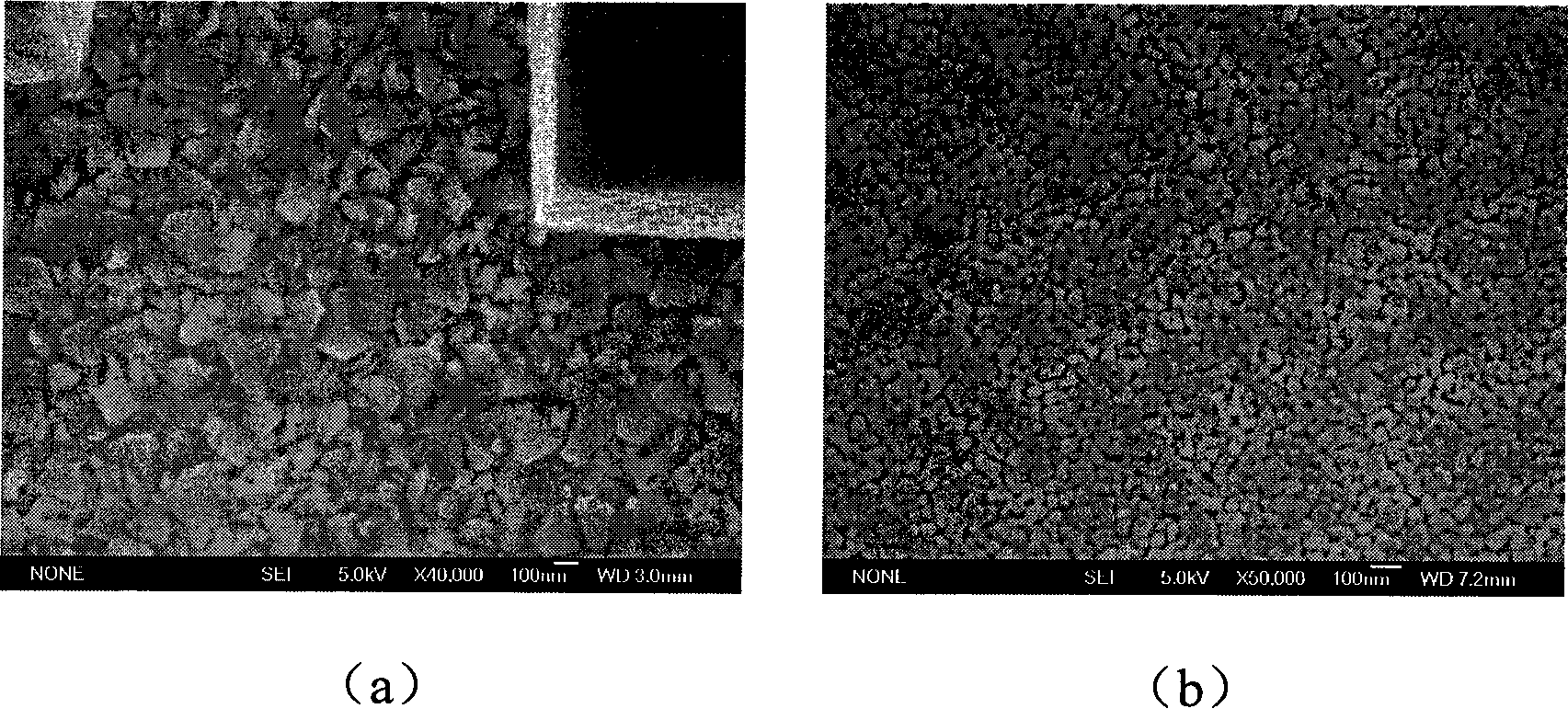

[0030] (1) Preparation of dense TiO 2 film layer

[0031] Stir tetrabutyl titanate and absolute ethanol evenly at a volume ratio of 1:4. During the stirring process, add 1 volume of dilute nitric acid aqueous solution with pH = 1, and then slowly add 1 volume of pure water, continue stirring for 60 minutes, and let it stand for a while. into TiO 2 Sol. The TiO that will be configured 2 The sol was spin-coated on the FTO conductive glass substrate at a speed of 2000r / min, dried at 80°C, put into a muffle furnace and sintered at 450°C for 30min at a heating rate of 4-5°C / min, and cooled naturally. dense nanocrystalline TiO 2 Thin film, transparent film, about 20-100nm thick.

[0032] (2) Preparation of porous TiO 2 film layer

[0033] Place the cleaned and dried FTO glass on the conductive surface, stick around it with 3M white tape to form a frame with a size of 0.5mm×0.5mm, and wrap the TiO2 prepared in step a with a glass rod. 2 The slurry is dripped on one end of the t...

Embodiment 2

[0037] (1) Preparation of dense TiO 2 film layer

[0038] Using Line-420 magnetron sputtering apparatus, more than 99.99% pure titanium target, filled with oxygen, the sputtering power is 300W, O 2 The gas flow rate is 10 sccm, and the protective gas Ar gas flow rate is 30 sccm. During sputtering, the vacuum degree was 2.0 Pa, the substrate temperature was 180° C., and the sputtering time was 1.5 hours. Annealed at 450°C for 30 minutes in air to form dense nanocrystalline TiO prepared by magnetron sputtering 2 Thin film, film thickness about 70nm.

[0039] (2) Preparation of porous TiO 2 film layer

[0040] The porous layer was printed by screen printing. Fine stainless steel mesh with a mesh size of 250 and an effective unit area of 20mm×8mm. After printing once, dry it, then print it a second time, repeat printing three times, and then anneal in a muffle furnace at 450°C for 30 minutes to form porous TiO. 2 The film layer has a film thickness of about 16 μm.

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com