On-line multi-mode time optimization scheduling method for steelmaking and continuous casting production

A technology for optimizing scheduling, steelmaking and continuous casting, applied in the information field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

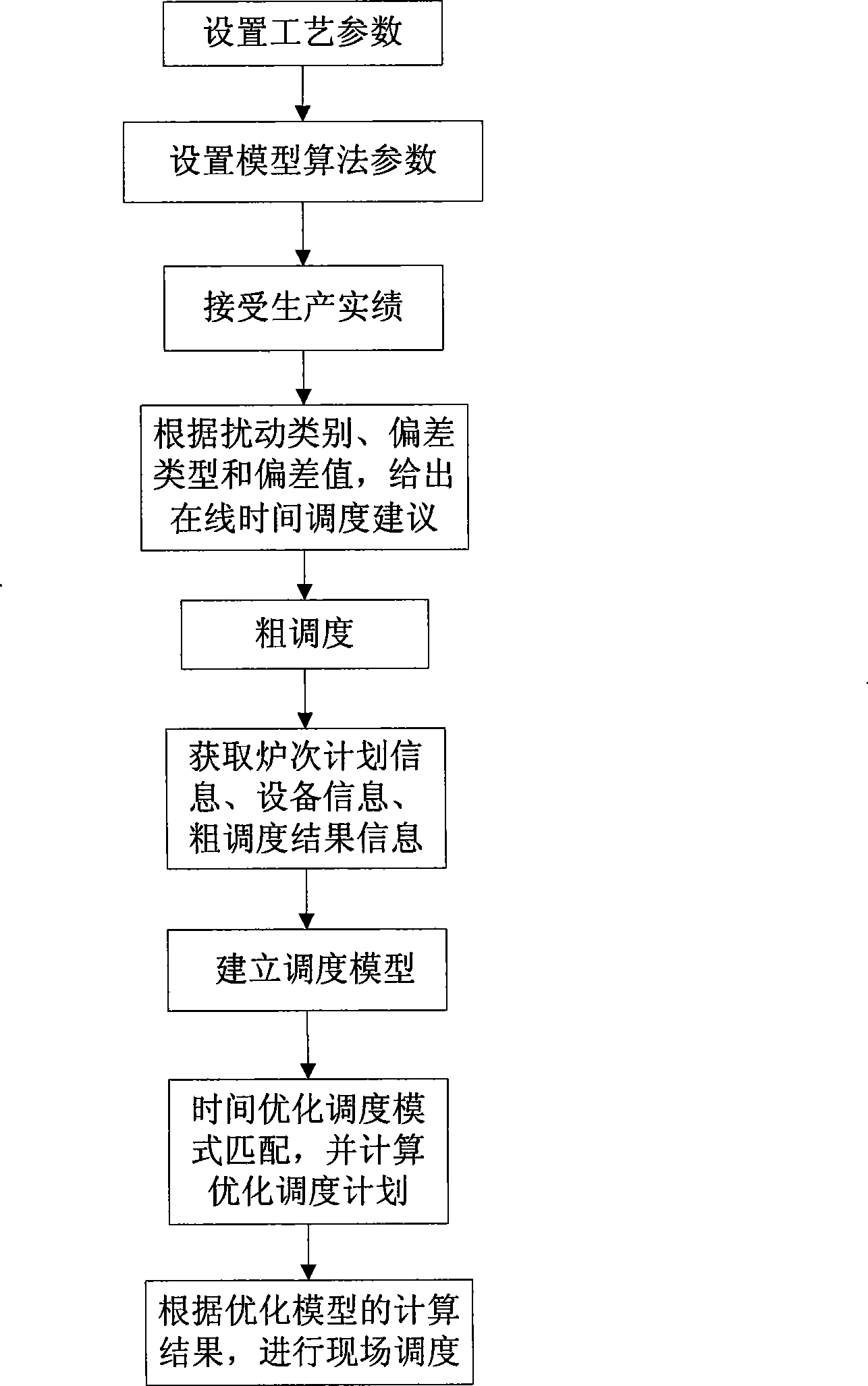

[0125] Taking the actual production scheduling problem of a certain iron and steel enterprise as an example, a multi-mode time-optimized scheduling method for steelmaking and continuous casting production of the present invention will be further described in conjunction with the accompanying drawings.

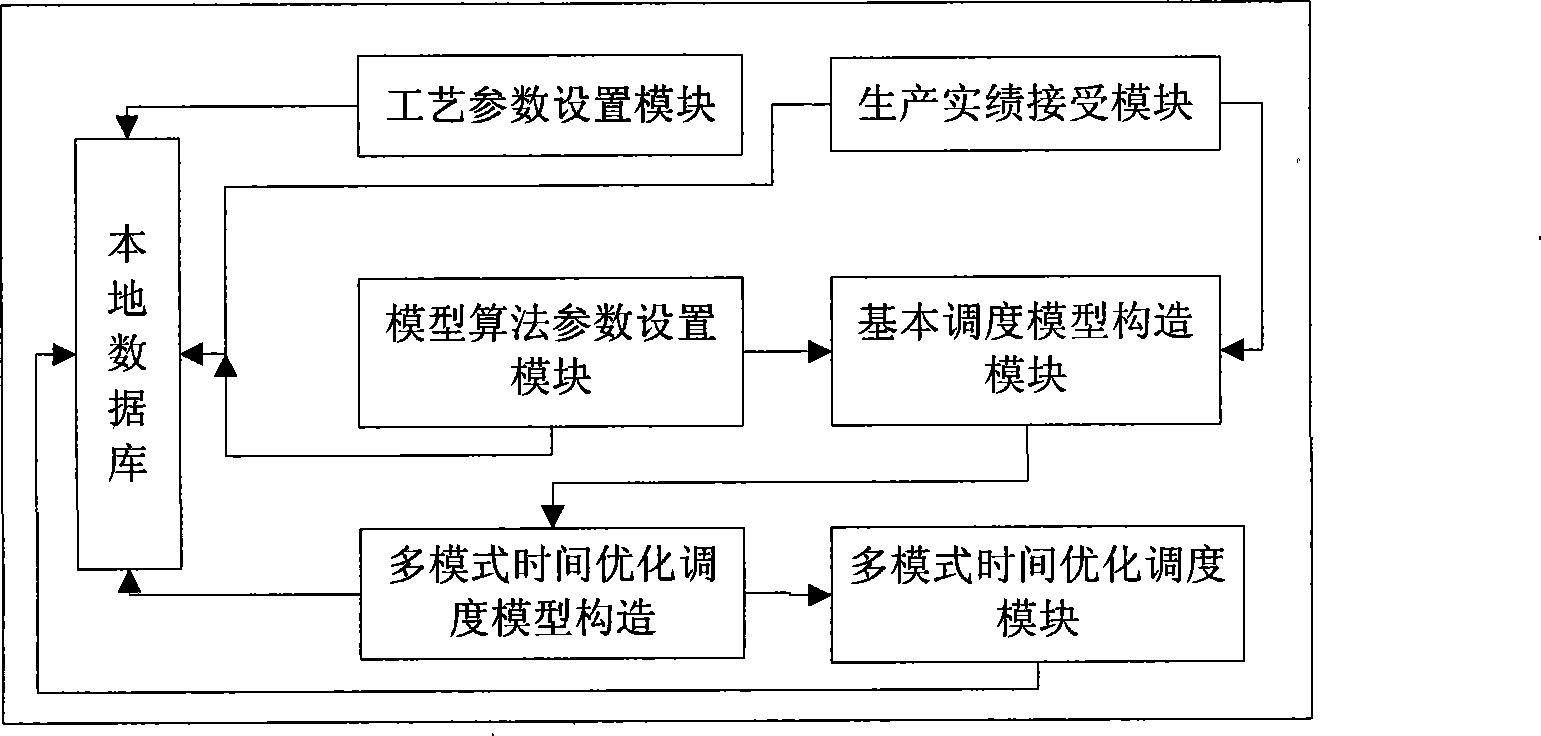

[0126] The system of the present invention includes a process parameter setting module, a production performance acceptance module, a model algorithm parameter setting module, a basic scheduling model construction module, a multi-mode time optimization scheduling model construction module, a multi-mode time optimization scheduling module and a local database Microsoft SQL Server2000, Among them, the local database Microsoft SQL Server2000 is respectively connected with the process parameter setting module, the production performance acceptance module, the model algorithm parameter setting module, the basic scheduling model construction module, the multi-mode time optimization sch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com