Method for preparing normal-temperature normal-pressure dyeable polyester pearl fiber

A pearl fiber and room temperature technology is applied in the field of preparation of dyeable polyester pearl fibers at room temperature and pressure, which can solve the problem of difficult to obtain bright and dense color, and achieve the effects of smooth fabric, soft luster and uniform tow evenness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation of nano-pearl powder composite Wash and dry 100 parts by weight of pearls with clear water, process them to 300 mesh with high-frequency vibration mill, and then configure them with 1500 parts by weight of deionized water according to the following ratio:

[0026] Table 1: Pearl Powder Recipe

[0027] serial number Pearl powder Heat stabilizers, Antioxidants Emulsifier 1 100 copies 0.1 tribasic sulfur 0.01 part 1 part polyglyceryl fatty acid ester

[0028] lead acid Irganox1010

2

100 copies 0.02 dibasic sub

lead phosphate 0.03 parts

Irganox1076 0.1 part soybean lecithin +0.5

part glyceryl tristearate

3

100 copies

0.05 barium stearate 0.001 copies

Irganox1330

0.1 part soybean lecithin

4

100 copies

0.1 lead stearate 0.006 copies

Irganox168

0.7 parts sorbitol

5

100 copies 0.001 lauric acid di

...

Embodiment 3

[0033] Preparation of normal temperature and normal pressure dyeable polyester pearl fiber The nano-pearl normal temperature and normal pressure dyeable polyester chips obtained in Example 2 were subjected to high-speed composite spinning according to the spinning process requirements. The melt temperature of spinning is controlled between 255-295°C. The heat-setting temperature is 140-220°C. Normal temperature and pressure dyeable polyester chips are produced by Zhejiang Chemical Fiber United Group Co., Ltd., and the brand name is Jinghua brand normal temperature and pressure dyeable polyester chips.

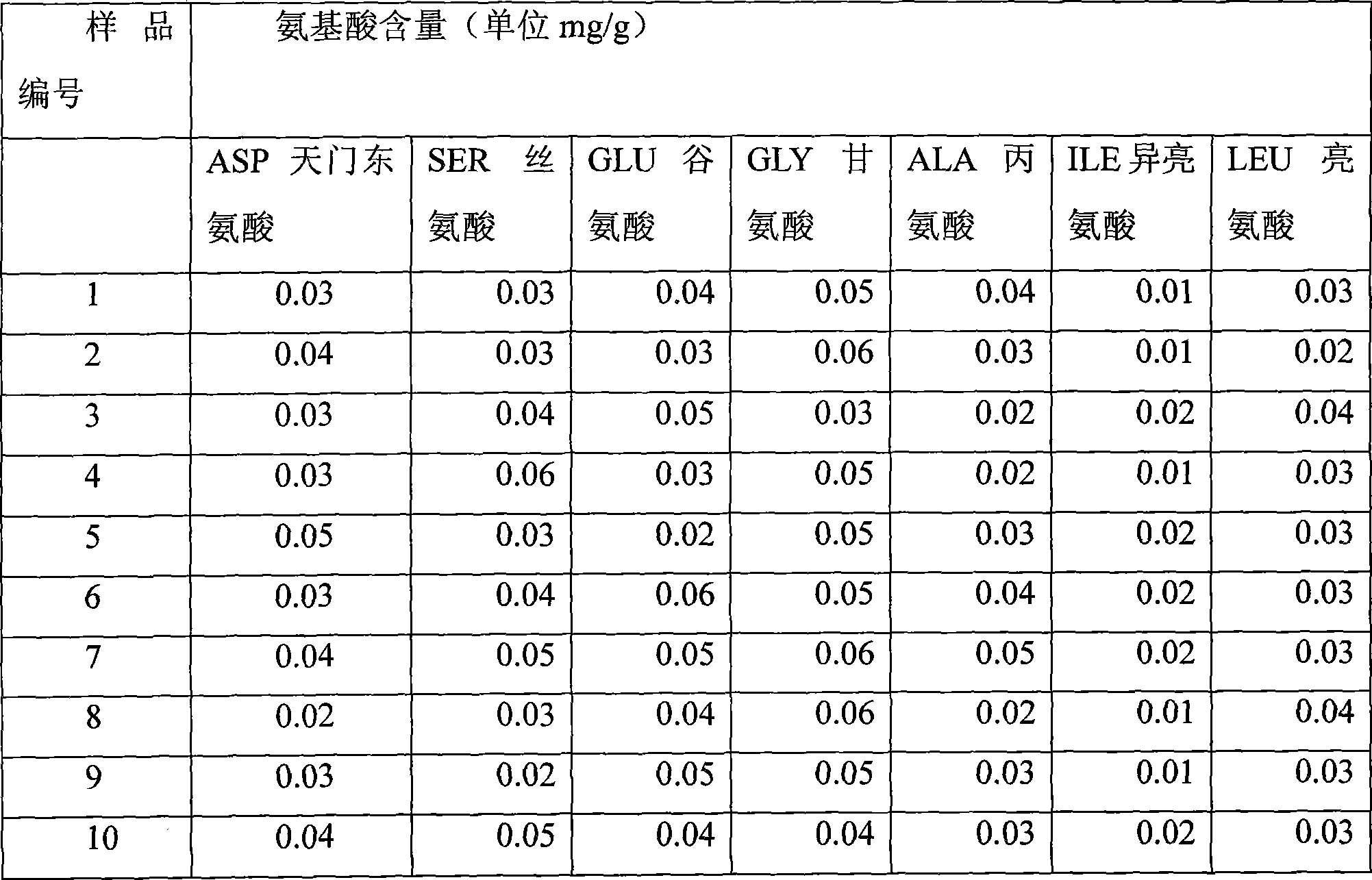

[0034] Table 2: Formulas and performance indicators of various normal temperature and pressure dyeable pearl fibers

[0035]

[0036] 23%

[0037] After spinning according to the ratio in Table 2, see Table 3 for the amino acid content tests of nano-pearl fibers with different formulations.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com