Photocatalytic self-cleaning nano-titania porcelain enamel substrate and method for preparing same

A nano-titanium dioxide, photocatalytic technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., to achieve the effects of low production cost, simple preparation process, and increased photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

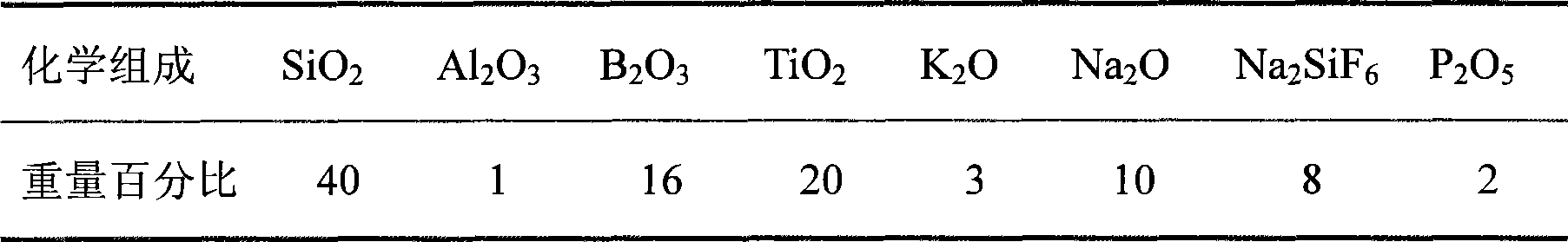

[0029] An enamel substrate for photocatalytic self-cleaning properties. The chemical composition of its raw materials is shown in the table below

[0030]

[0031] (1) According to the above raw material composition SiO 2 40, Al 2 o 3 1, B 2 o 3 16.TiO 2 20,K 2 o 3 , Na 2 O 10,Na 2 SiF 6 8,P 2 o 5 2. Convert various ingredients into quartz, feldspar, borax, titanium dioxide, soda ash, ice crystal, sodium dihydrogen phosphate and other raw materials, weigh and mix them, put them in a crucible, and melt them at 1250 ° C. After melting, put them into tap water Quenching, removing and drying at 120°C to obtain enamel frit.

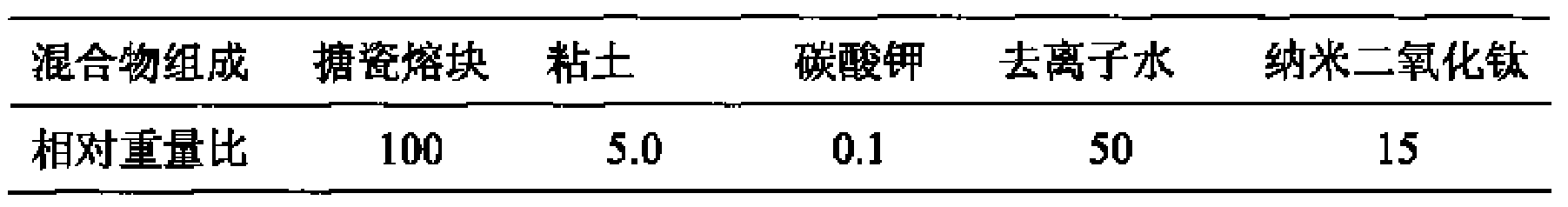

[0032] (2) Mix the enamel frit obtained in the above step (1) according to the composition in the table below, then ball mill and grind for 1 to 2 hours, and finally pass through an 80-mesh sieve to obtain an enamel glaze for future use.

[0033]

[0034] (3) Take 100*100*2mm steel plate or cast iron, carry out derusting and degreasin...

Embodiment 2

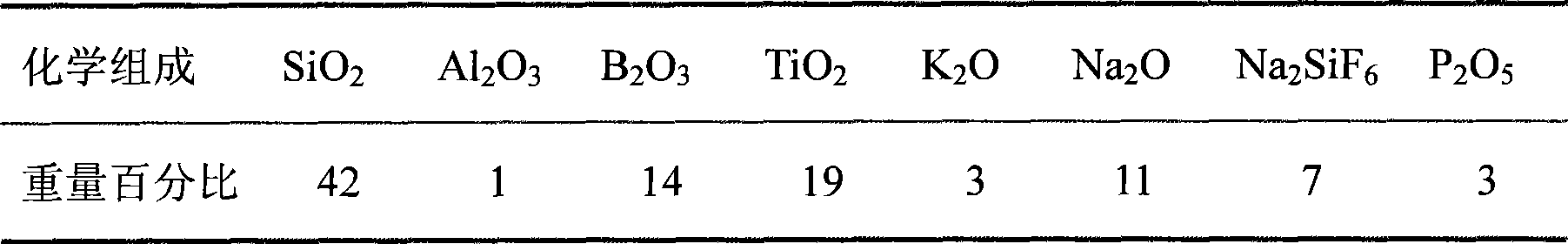

[0038] An enamel substrate for photocatalytic self-cleaning properties. The chemical composition of its raw materials is shown in the table below

[0039]

[0040] (1), according to the composition of SiO 2 42, Al 2 o 3 1, B 2 o 3 14. TiO 2 19,K 2 O3, Na 2 O 11,Na 2 SiF 6 7, P 2 o 5 3. Convert various ingredients into quartz, feldspar, borax, titanium dioxide, soda ash, ice crystals, sodium dihydrogen phosphate and other raw materials, weigh and mix them, put them in a crucible, and melt them at 1250 ° C. After melting, put them into tap water Quenching, removing and drying at 120°C to obtain enamel frit.

[0041] (2) Mix the enamel frit obtained in step (1) according to the composition in the table below, then ball mill and grind for 1 to 2 hours, and finally pass through an 80-mesh sieve for later use.

[0042]

[0043] (3), take 100*100*2mm steel plate or cast iron, 10% H 2 SO 4 Carry out derusting and degreasing treatment with 8wt% industrial soa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com