Twisting-resistant self-restoring lead core shape memory alloy damper

A memory alloy, anti-torsion technology, applied in building components, shockproof and other directions, can solve the problems of residual deformation of passive dampers, single-direction vibration reduction capacity, limited energy consumption capacity, etc., to achieve large recovery deformation, simple structure, and improved energy consumption ability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The implementation steps of the present invention will be described in detail below in conjunction with the technical scheme and accompanying drawings.

[0016] Step 1. Under the action of small and large earthquakes, analyze the engineering structure, and determine the size and parameters of the damper according to the performance requirements to be achieved.

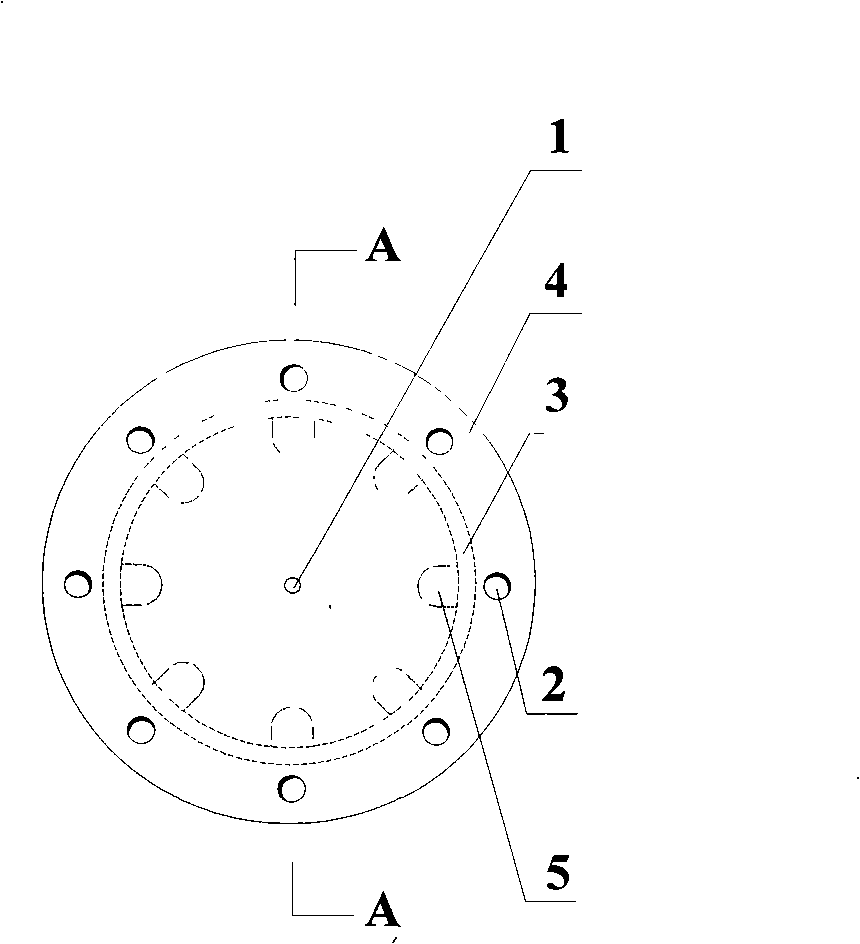

[0017] Step 2. Process one shape memory alloy cylinder 3 of the shape memory co-extrusion bead 5, two shape memory alloy flanges 4 with screw holes, and firmly fix the two flanges on the shape memory alloy cylinder 3 Up and down the mouth.

[0018] Step 3. Fill the shape memory alloy cylinder 3 with lead through the lead filling hole 1 on the flange, and then seal the lead filling hole 1 firmly.

[0019] Step 4. Through the screw hole 2 on the flange, position the damper where torsional vibration needs to be controlled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com