Method for testing abrasion resistance of ultra-high molecular mass polyethylene

A technology with ultra-high molecular weight and wear resistance, applied in the field of polymer material testing and evaluation, it can solve the problems of indistinguishable, inability to evaluate the wear resistance of high wear resistance plastics such as UHMWPE, and time-consuming, and achieve the effect of reasonable evaluation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

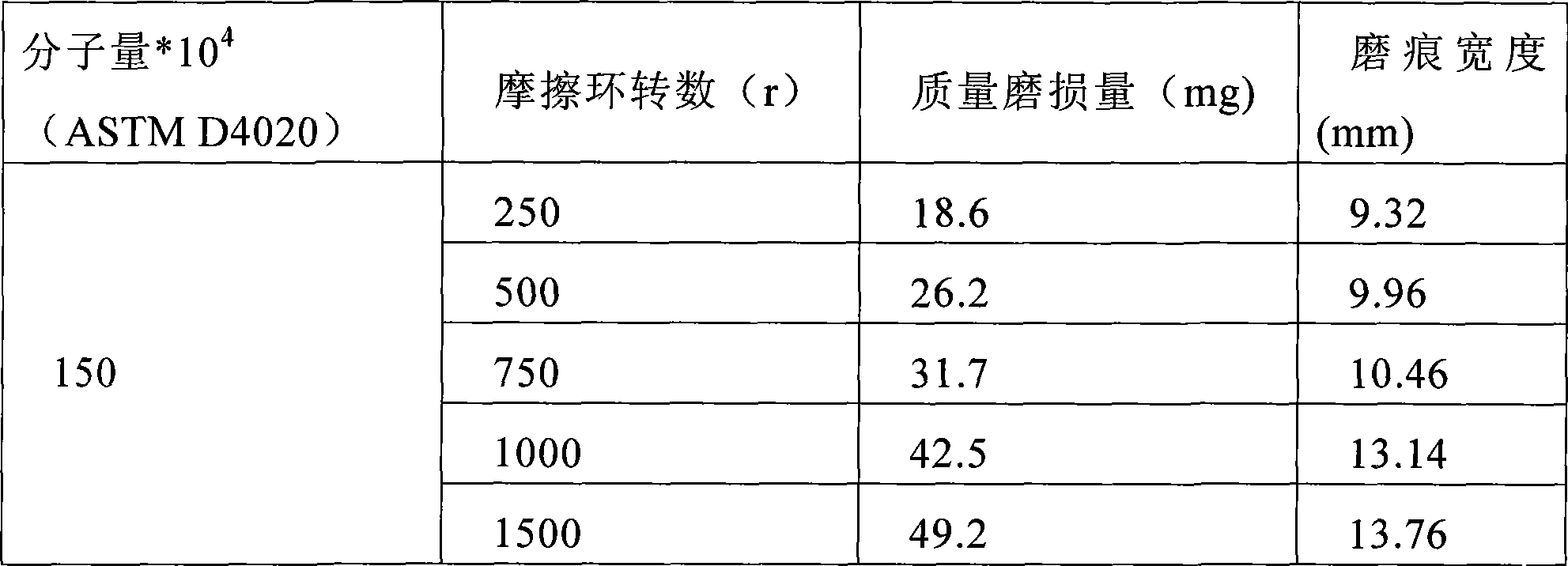

[0020] Put the UHMWPE powder with a molecular weight of 1.5 million into a custom-made abrasive tool, adjust the temperature, pressure and pressing time of the XLB flat vulcanizer, and obtain a test sample with a size of 30×7×6±0.2mm. Before the test, visually check whether the surface of the spline is smooth, whether there are defects such as bubbles, cracks, delamination, obvious impurities, and processing damage, and measure the length, width, and height of the spline with a vernier caliper to observe whether the size of the spline is within the required error range. The splines were polished with 400# metallographic sandpaper, scrubbed with wine clear cotton balls, dried in an infrared drying oven, and weighed.

[0021] Fix the friction ring glued with 280# sandpaper on the MH-20 friction and wear testing machine. The rotation speed of the fixed friction ring is 200r / min. Put the sample into the fixture and fix it on the testing machine. After the number of rotations is 25...

Embodiment 2

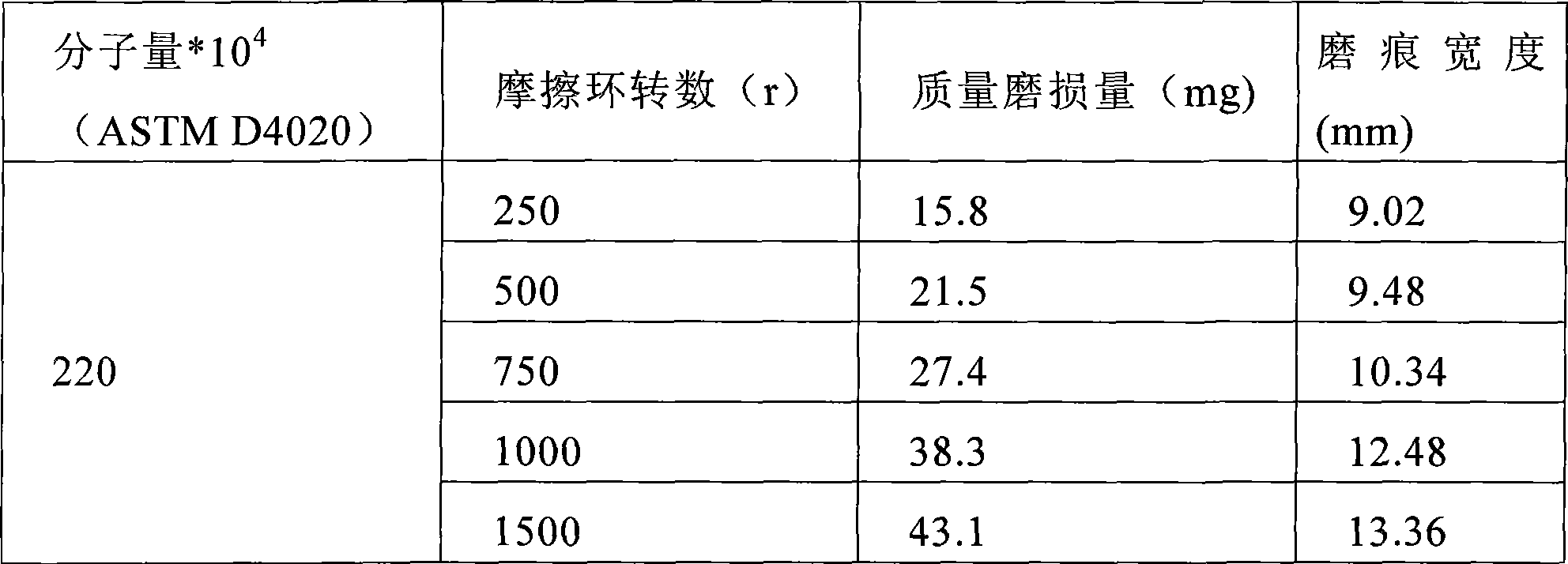

[0023] Put the UHMWPE powder with a molecular weight of 2.2 million into a custom-made abrasive tool, adjust the temperature, pressure and pressing time of the XLB flat vulcanizer, and obtain a test sample with a size of 30×7×6±0.2mm. Before the test, visually check whether the surface of the spline is smooth, whether there are defects such as bubbles, cracks, delamination, obvious impurities, and processing damage, and measure the length, width, and height of the spline with a vernier caliper to observe whether the size of the spline is within the required error range. The splines were polished with 400# metallographic sandpaper, scrubbed with wine clear cotton balls, dried in an infrared drying oven, and weighed.

[0024] Fix the friction ring glued with 280# sandpaper on the MH-20 friction and wear testing machine. The rotation speed of the fixed friction ring is 200r / min. Put the sample into the fixture and fix it on the testing machine. After the number of rotations is 25...

Embodiment 3

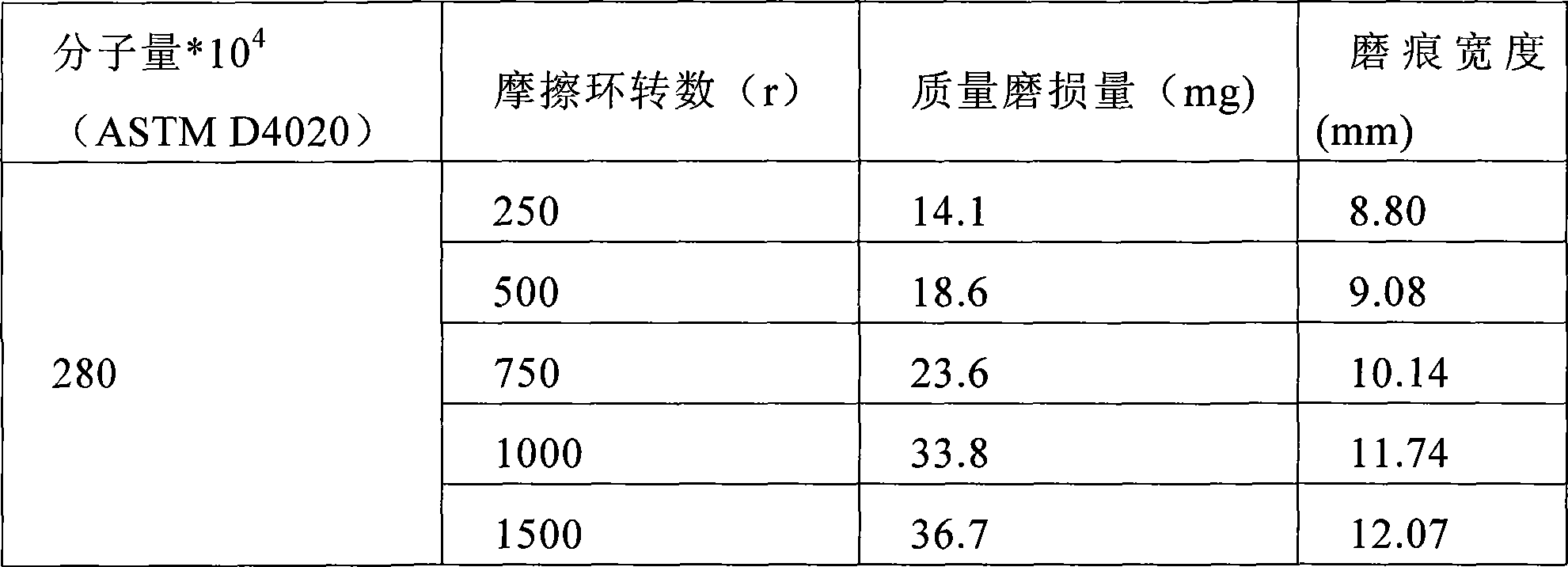

[0026] Put the UHMWPE powder with a molecular weight of 2.8 million into a custom-made abrasive tool, adjust the temperature, pressure and pressing time of the XLB flat vulcanizer, and obtain a test sample with a size of 30×7×6±0.2mm. Before the test, visually check whether the surface of the spline is smooth, whether there are bubbles, cracks, delamination, obvious impurities and processing damage, etc., and use a vernier caliper to measure the length, width, and height of the spline, and observe whether the size of the spline is within the required error range. The splines were polished with #400 metallographic sandpaper, scrubbed with wine clear cotton balls, dried in an infrared drying oven, and weighed.

[0027] Fix the friction ring glued with 280# sandpaper on the MH-20 friction and wear testing machine. The rotation speed of the fixed friction ring is 200r / min. Put the sample into the fixture and fix it on the testing machine. After the number of rotations is 250r, 500...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com