Color solid plate manufacture method

A manufacturing method and technology of solid wood boards, applied in the jointing of wooden veneers, manufacturing tools, wood layered products, etc., can solve the problems of soft materials, flammability, and corrosion resistance, and achieve the effect of strong plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

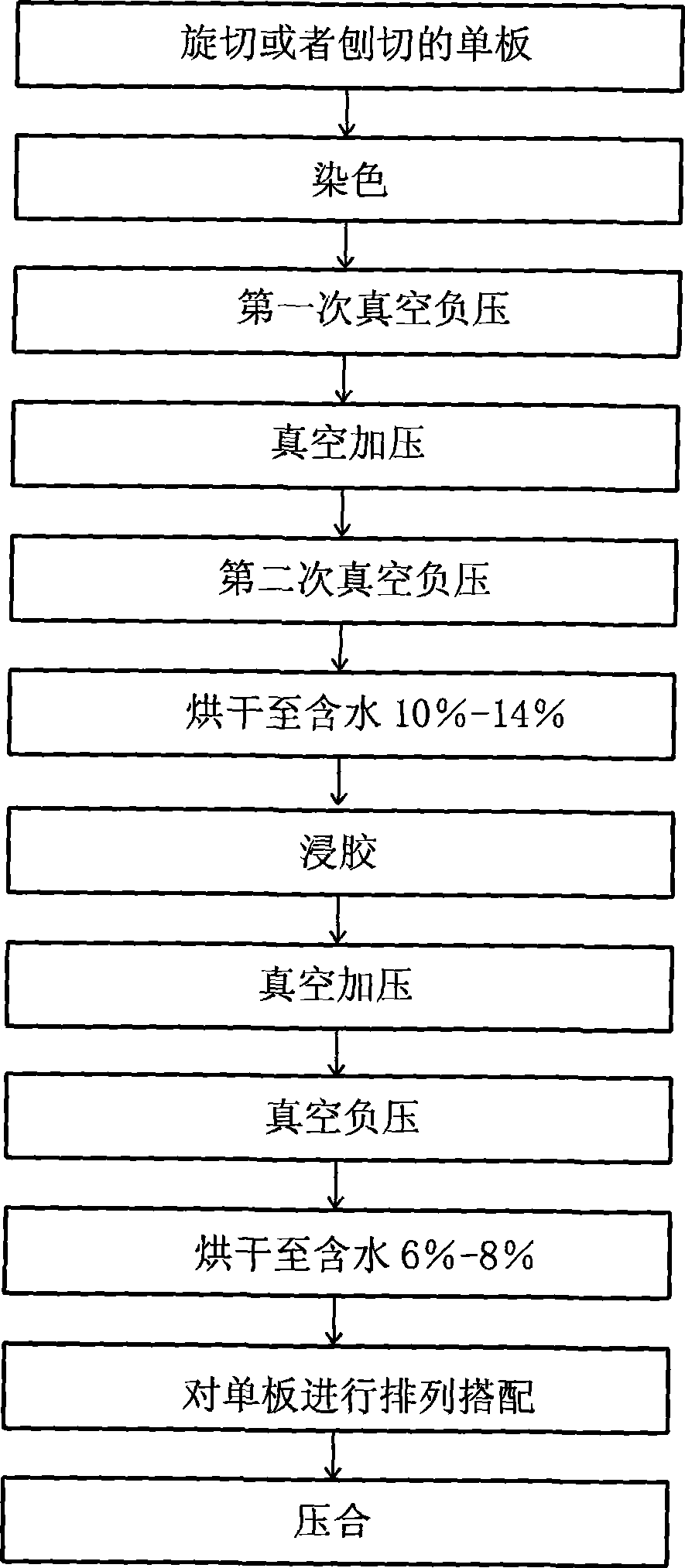

Method used

Image

Examples

Embodiment 1

[0053] Embodiment one: adopt 1.5m 3 Birch, (density 1:1.2) as an example, to make ink walnut colorful wood.

[0054] a) Slicing 1mm-10mm thick, preferably 2mm thick veneer skin 0.5m 3 , rotary cut 0.1-2mm thick, preferably 1mm thick veneer skin 1.0m 3 , total: 1.5m 3 .

[0055] b) Add water to the pressure vessel, about 1.5m 3 -2m 3 , add water and preheat to about 40°C, put in dyes, among them, red 1.29kg, accounting for 43%, green 1.38kg, accounting for 46%, blue: 0.33kg, accounting for 11%, a total of 3kg dyes.

[0056] a) Put the prepared veneer into a stainless steel box, put it into a pressure vessel, close the tank mouth of the container, check and lock the tank mouth, and humidify to 90%.

[0057]b) Start the vacuum pump and open the valve to carry out vacuum work negative pressure in the pressure vessel, the pressure is 1Kg-3Kg / cm 2 , preferably 2kg / cm 2 , time 20-30 minutes, preferably 30 minutes, shut down and return to normal pressure.

[0058] c) Start th...

Embodiment 2

[0069] Embodiment two: adopt 1.5m 3 The lotus birch (density 1:1.2) is taken as an example to make ink walnut colorful wood.

[0070] a) Rotary cut 1.2mm thick veneer 1.4m 3 .

[0071] b) Add water to the pressurized container, 1.8m 3 -2.3m 3 After adding water, it can be preheated to about 45°C, and put in basic dyes, red 3.36kg, accounting for 48%, green 3.36kg, accounting for 48%, blue 0.28kg, accounting for 40%, a total of 7kg dyes.

[0072] a) Put the prepared veneer into the stainless steel mesh and put it into the pressure vessel, close the vessel, check and lock the mouth of the tank, and heat to 90°C.

[0073] b) Start the vacuum pump to vacuum the container at a negative rate of 2kg / cm 2 , After 30 minutes, stop the machine for back pressure.

[0074] c) Start the vacuum press and pressurize the container to 6kg / cm 2 , After 1 hour, close the valve to stop the machine and discharge the pressure.

[0075] d) Start the vacuum pump, open the valve to carry out v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com