Preparation method of carbide-Co/Ni composite powder and hard alloy

A cemented carbide and composite powder technology, applied in the fields of hydrometallurgy and powder metallurgy, can solve the problems of excessive WC particle breakage, etc., and achieve the effect of short process, low cost and less emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

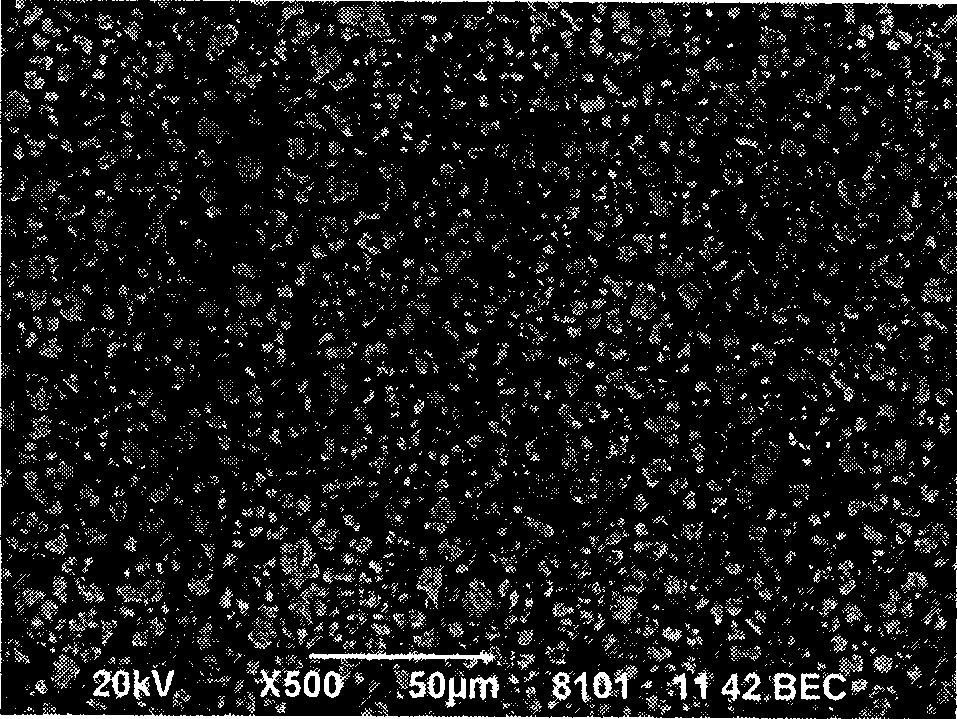

[0024] Example 1 WC-Co-Ni composite powder was prepared according to the composition of WC-6.25wt.%Co-6.25wt.%Ni. WC with a FSSS of 6.5 μm was selected as the raw material, and the mechanical pretreatment was carried out by ball milling in a ball mill for 6 hours at a ball-to-material ratio of 3:1. 200g NH 4 Cl and 53.82g CoCl 2 ·6H 2 O, 53.95g NiCl 2 ·6H 2 O was dissolved in deionized water respectively; the two were mixed and filtered; 64.73 g concentrated NH was added 3 Water, configure 1L cobalt ammonia complex solution. 200 g of the above-mentioned WC powder and the above-mentioned cobalt-ammonia complex solution were put into a 2L autoclave. with N 2 After exhausting the air in the kettle, pass in H 2Make the pressure in the kettle reach 3.5MPa, adjust the rotation speed of the autoclave to 1000r / min, keep the temperature at 170°C, and keep the temperature at 3h to carry out the hydrothermal high-pressure hydrogen reduction reaction. After the reaction, the obta...

Embodiment 2

[0025] Example 2 WC-Co composite powder was prepared according to WC-12.5wt.% Co composition. WC with a FSSS of 6.5 μm was selected as the raw material, and the mechanical pretreatment was carried out by ball milling in a ball mill for 6 hours at a ball-to-material ratio of 3:1. 250g (NH 4 ) 2 SO 4 with 136.24g CoSO 4 ·7H 2 O was dissolved in deionized water respectively; the two were mixed and filtered; 64.73 g concentrated NH was added 3 water (NH 3 :Co=2.2:1), configure 1L cobalt ammonia complex solution. 200 g of the above-mentioned WC powder and the above-mentioned cobalt-ammonia complex solution were put into a 2L autoclave. with N 2 After exhausting the air in the kettle, pass in H 2 Make the pressure in the kettle reach 3.5MPa, adjust the rotation speed of the autoclave to 1000r / min, keep the temperature at 170°C, and keep the temperature at 3h to carry out the hydrothermal high-pressure hydrogen reduction reaction. After the reaction was completed, the WC-Co...

Embodiment 3

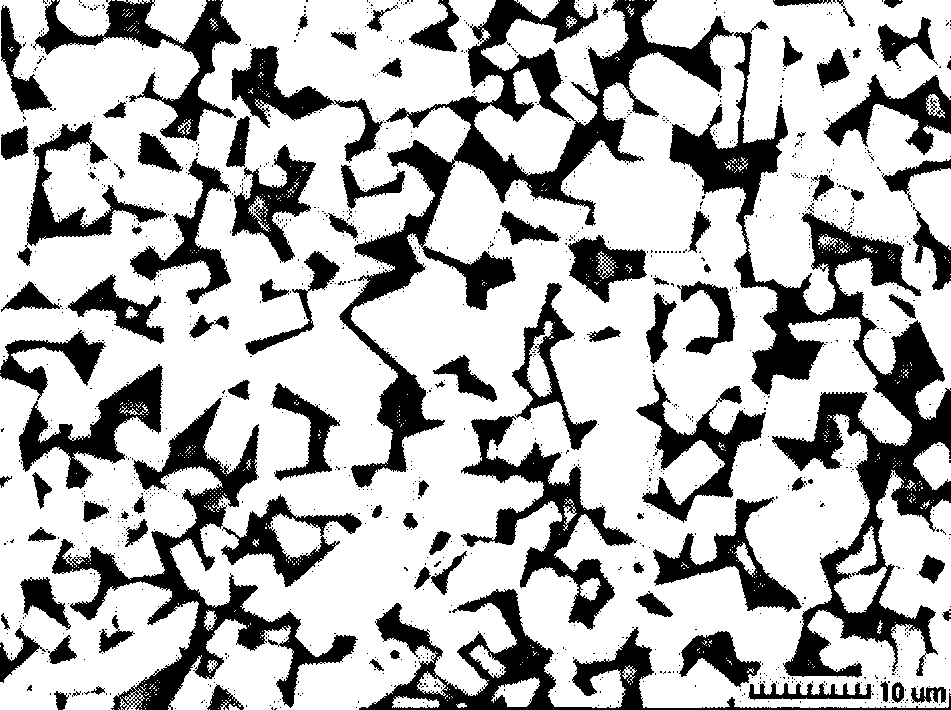

[0026] Example 3 WC-Co composite powder was prepared according to the WC-8wt.% Co composition. Select WC with FSSS of 12.0 μm as raw material, and perform mechanical pretreatment by ball milling in a ball mill for 8 hours at a ball-to-material ratio of 3:1. 150gNH 4 Cl and 70.18g CoCl 2 ·6H 2 O was dissolved in deionized water respectively; the two were mixed and filtered; 39.40 g concentrated NH was added 3 water (NH 3 :Co=2.2:1), configure 1L cobalt ammonia complex solution. 200 g of the above-mentioned WC powder and the above-mentioned cobalt-ammonia complex solution were put into a 2L autoclave. The rest of the process parameters are the same as in Example 2. The results of chemical analysis showed that the Co content in the WC-Co composite powder was 7.41wt.%, the O content (total oxygen analysis) was 0.1091wt.%, the H content was 0.0104wt.%, and the Co yield was 92.6%. The combination of the metallographic observation of the polished section of the alloy shows tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com