Air indirect cooling method and system for ammonia absorption type composite refrigeration cycle

A refrigeration cycle and composite refrigeration technology, applied in the condenser of textile, chemical industry, metallurgy, and steam turbine generator set, can solve the problems of reducing equipment size, difficulty in large-scale, large water consumption, etc., achieving easy implementation and novel concept. Unique, Technologically Proven Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

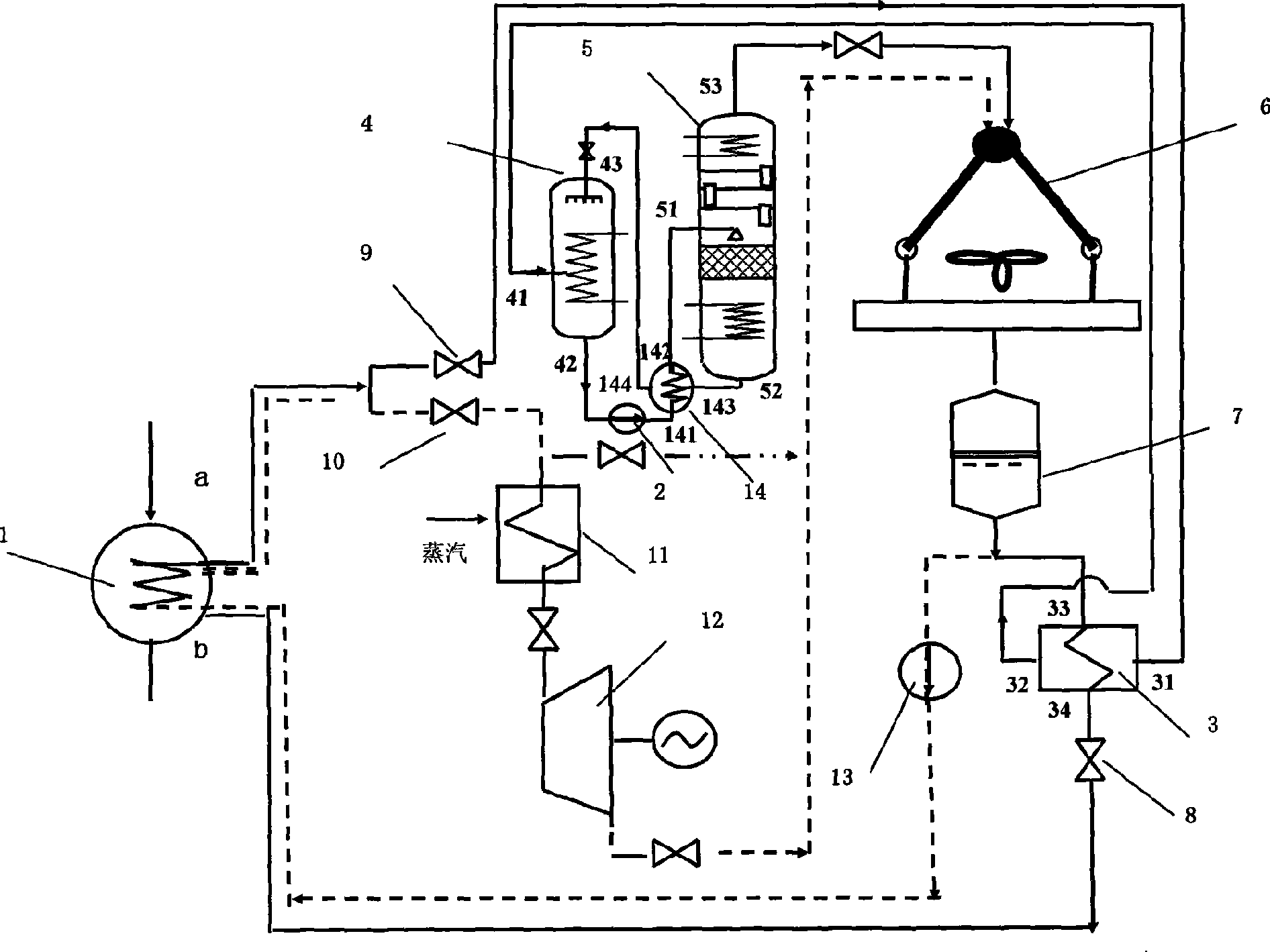

[0043] Embodiment 1: The air indirect cooling system of the ammonia water absorption compound refrigeration cycle

[0044] refer to figure 1 , the air indirect cooling system of the ammonia-water absorption composite refrigeration cycle uses a two-phase conversion heat exchanger 1 to replace the wet-condensing condenser in the steam power cycle system. Between the output end a and the input end b of the refrigerant on the low temperature side of the two-phase conversion heat exchanger, an indirect air cooling system of the positive refrigeration cycle (the operation route shown by the solid line in the figure) and an indirect air cooling system of the reverse refrigeration cycle are coupled in parallel system (the running route shown by the dotted line in the figure).

[0045] The output end a of the refrigerant on the low temperature side of the two-phase conversion heat exchanger 1 communicates with the shell-side input end 31 of the subcooler 3 through the valve 9, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com