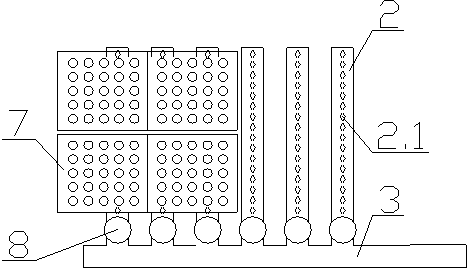

Sectional high-performance strontium ferrite presintering equipment and presintering method thereof

A strontium ferrite, high-performance technology, used in strontium ferrite pre-burning equipment, the device's pre-burning field, can solve the problems that cannot meet the temperature of different temperature zones, sufficient redox atmosphere conditions, large shrinkage fluctuations, reaction Incomplete and other problems, to achieve the effect of novel ideas, energy saving and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

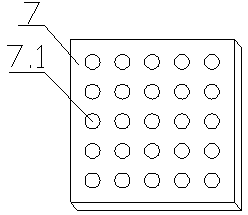

Method used

Image

Examples

Embodiment 1

[0040] A method for producing pre-sintered material with segmented high-performance strontium ferrite pre-sintered equipment, specifically according to the following steps:

[0041] The first step, prepare the block

[0042] 1) Ingredients: Weigh the raw materials according to the following weight ratio, Fe 2 o 3 : 87%, SrCO 3 : 13%, Al 2 o 3 :

[0043] 0.25%, SiO 2 : 0.25%, La 2 o 3 : 2.5%, Co 2 o 3 :2%;

[0044] 2) Primary ball milling: Add raw materials and auxiliary materials to a horizontal ball mill and add water for wet milling, according to the weight of materials, balls and water

[0045] The amount ratio is 1:3:2, and the particle size reaches 1.0μm;

[0046] 3) Forming: The ground slurry is press-filtered and formed to obtain raw material blocks;

[0047] The second step, equipment inspection

[0048] Check whether the equipment of each part of the pre-burning equipment is in normal operation, whether the instrument display of the temperature in each t...

Embodiment 2

[0064] A method for producing pre-sintered material with segmented high-performance strontium ferrite pre-sintered equipment, specifically according to the following steps:

[0065] The first step, prepare the block

[0066] 1) Ingredients: Weigh the raw materials according to the following weight ratio, Fe 2 o 3 : 86%, SrCO 3 : 14%, Al 2 o 3 :

[0067] 0.35%, SiO 2 : 0.4%, La 2 o 3 : 3%, Co 2 o 3 : 2.5%

[0068] 2) Primary ball milling: Add raw materials and auxiliary materials to a horizontal ball mill and add water for wet milling, according to the weight of materials, balls and water

[0069] The amount ratio is 1:3:2, and the particle size reaches 1.0μm;

[0070] 3) Forming: The ground slurry is press-filtered and formed to obtain raw material blocks;

[0071] The second step, equipment inspection

[0072] Check whether the equipment of each part of the pre-burning equipment is in normal operation, whether the instrument display of the temperature in each te...

Embodiment 3

[0088] A method for producing pre-sintered material with segmented high-performance strontium ferrite pre-sintered equipment, specifically according to the following steps:

[0089] The first step, prepare the block

[0090] 1) Ingredients: Weigh the raw materials according to the following weight ratio, Fe 2 o 3 : 87%, SrCO 3 : 13%, Al 2 o 3 :

[0091] 0.25%, SiO 2 : 0.25%, La 2 o 3 : 2.5%, Co 2 o 3 : 2.8%

[0092] 2) Primary ball milling: Add raw materials and auxiliary materials to a horizontal ball mill and add water for wet milling, according to the weight of materials, balls and water

[0093] The amount ratio is 1:3:2, and the particle size reaches 1.0μm;

[0094] 3) Forming: The ground slurry is press-filtered and formed to obtain raw material blocks;

[0095] The second step, equipment inspection

[0096] Check whether the equipment of each part of the pre-burning equipment is in normal operation, whether the instrument display of the temperature in each...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com