Method for preparing hydroxyapatite/silk fibroin compound porous stand material

A technology of hydroxyapatite and silk fibroin, which is applied in medical science, prosthesis and other directions, can solve the problems of high brittleness, insufficient mechanical properties and slow degradation of hydroxyapatite, and achieves less reagents, cheap reagents, high performance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] 2. Preparation of 5% silk fibroin solution by weight concentration:

[0033] (1) the fibrous silk fibroin after degumming is 50% CaCl in weight percent concentration 2 In the solution, the weight ratio is 1:25, the temperature is 98°C, and the time is 5 minutes. After dissolving, filter and dialyze to obtain a silk fibroin solution with a weight concentration of 5%.

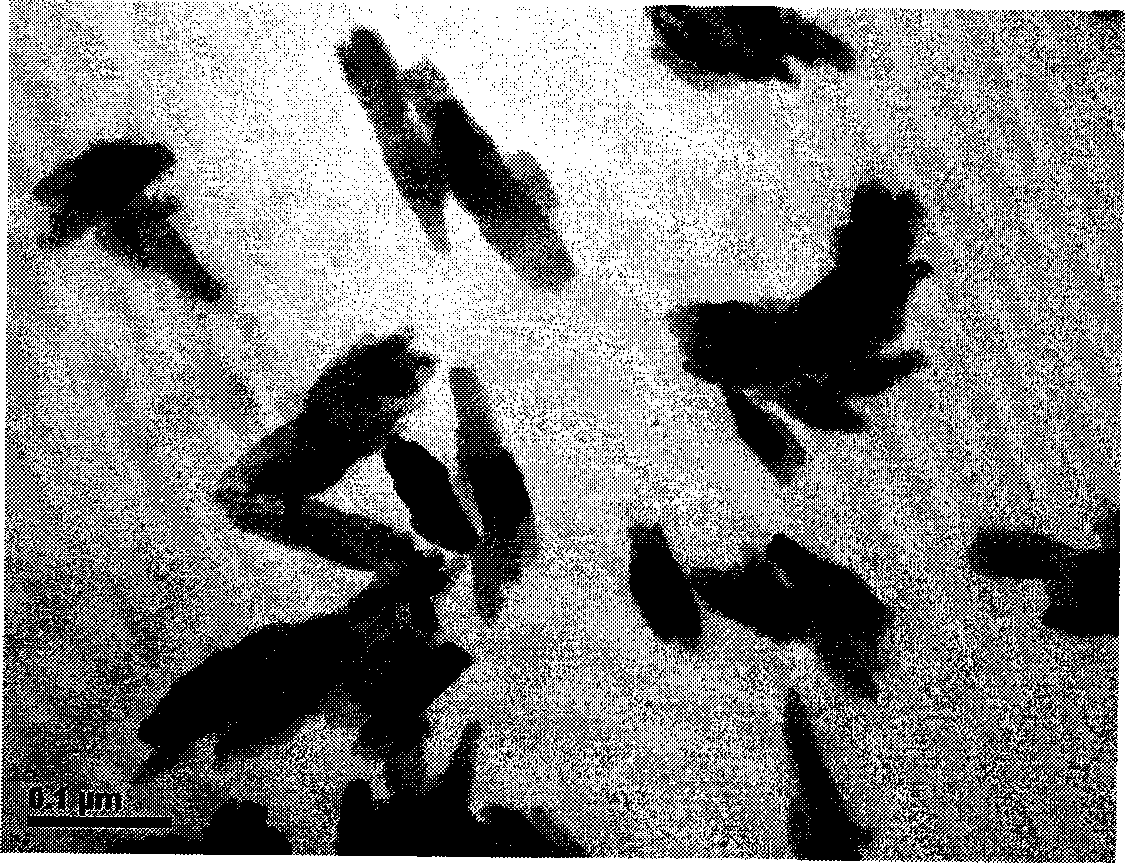

[0034] 3. Preparation of hydroxyapatite homogenate:

[0035] (1) 700ml of 60°C saturated Ca(OH) 2 The solution was placed in a water bath at 60°C, and 10% wt of H was slowly added dropwise 3 PO 4 Solution 11ml, during the dropping process, use a magnetic stirrer to continuously and rapidly stir and maintain the water temperature. The digital display pH meter monitors the pH of the solution. When the pH of the solution is lower than 7.0, add ammonia water dropwise to it, and adjust the pH of the solution to maintain at 8.7;

[0036] (2) After stirring for 3 hours, place it at 25°C for 48 hours, pour off...

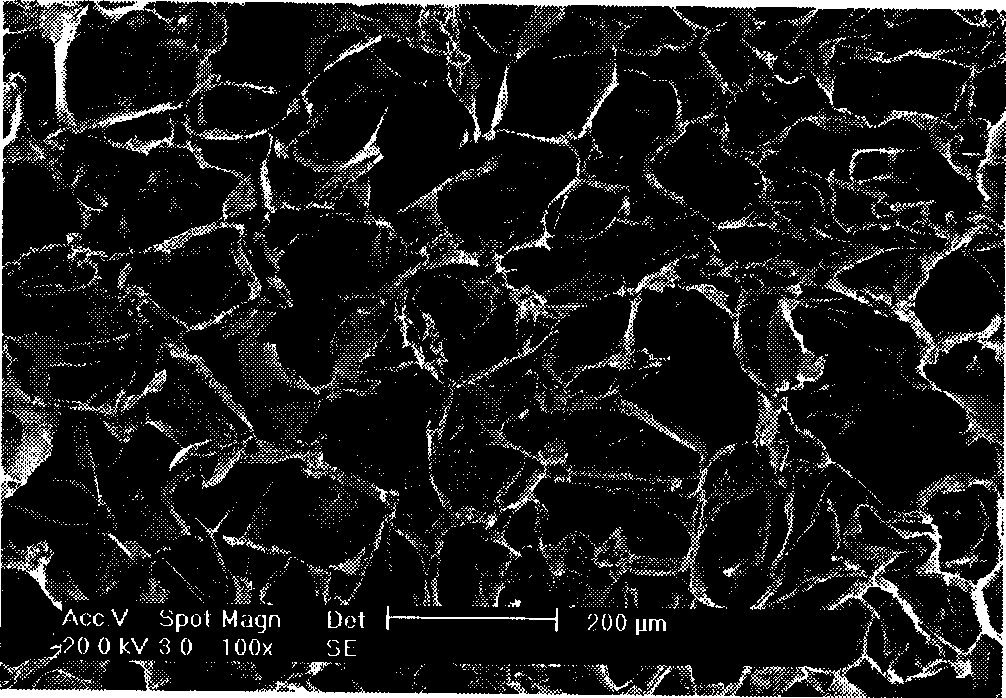

Embodiment 1

[0038] (1) Accurately weigh a certain mass of hydroxyapatite homogenate, stir continuously with a magnetic stirrer and keep the water temperature at 25°C, and slowly add silk fibroin solution dropwise therein. Make the ratio of HA to SF 1:9.

[0039] (2) Put the mixed solution of hydroxyapatite and silk fibroin into an ultrasonic cleaner, and vibrate for 3-5 minutes.

[0040] (3) Take out the mixed solution, slowly dropwise add glutaraldehyde crosslinking agent (commercially available) with a final concentration of 0.03% therein, and stir slowly with a magnetic stirrer evenly.

[0041] (4) Quickly transfer the mixed solution into a 24-well cell culture plate, and immediately put it into a -20°C refrigerator for 12 hours to pre-freeze.

[0042] (5) Take out the sample-loaded cell culture plate after freezing for 12 hours, return to temperature for 10 minutes at 25°C, and then put it back into the -20°C refrigerator for another 24 hours.

[0043] (6) Take out the sample-loaded...

Embodiment 2

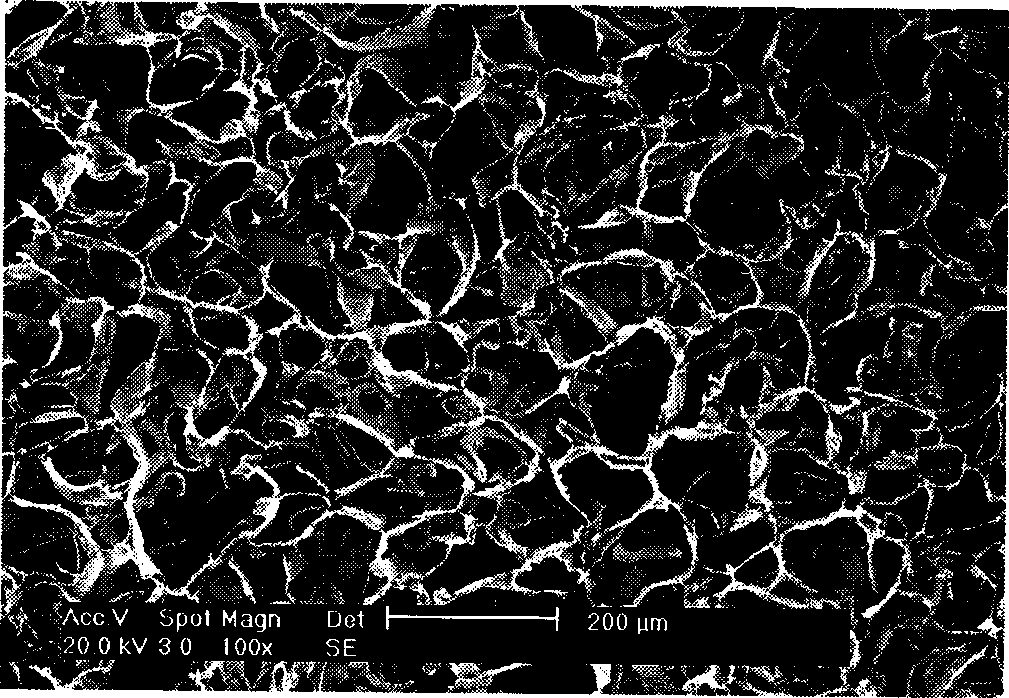

[0045] (1) Accurately weigh a certain mass of hydroxyapatite homogenate, stir continuously with a magnetic stirrer and keep the water temperature at 25°C, and slowly add silk fibroin solution dropwise therein. Make the ratio of HA to SF 3:7.

[0046] (2) Put the mixed solution of hydroxyapatite and silk fibroin into an ultrasonic cleaner, and vibrate for 3-5 minutes.

[0047] (3) Take out the mixed solution, slowly add a glutaraldehyde crosslinking agent with a final concentration of 0.03% dropwise therein, and stir slowly with a magnetic stirrer evenly.

[0048] (4) Quickly transfer the mixed solution into a 24-well cell culture plate, and immediately put it into a -20°C refrigerator for 12 hours to pre-freeze.

[0049] (5) Take out the sample-loaded cell culture plate after freezing for 12 hours, return to temperature for 20 minutes at 25°C, and then put it back into the -20°C refrigerator for another 24 hours.

[0050] (6) Take out the sample-loaded cell culture plate aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com