Production method for inner transparent collecting electrode IGBT with polysilicon as service life control layer

A technology for life control and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., and can solve problems such as no manufacturing method is given

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

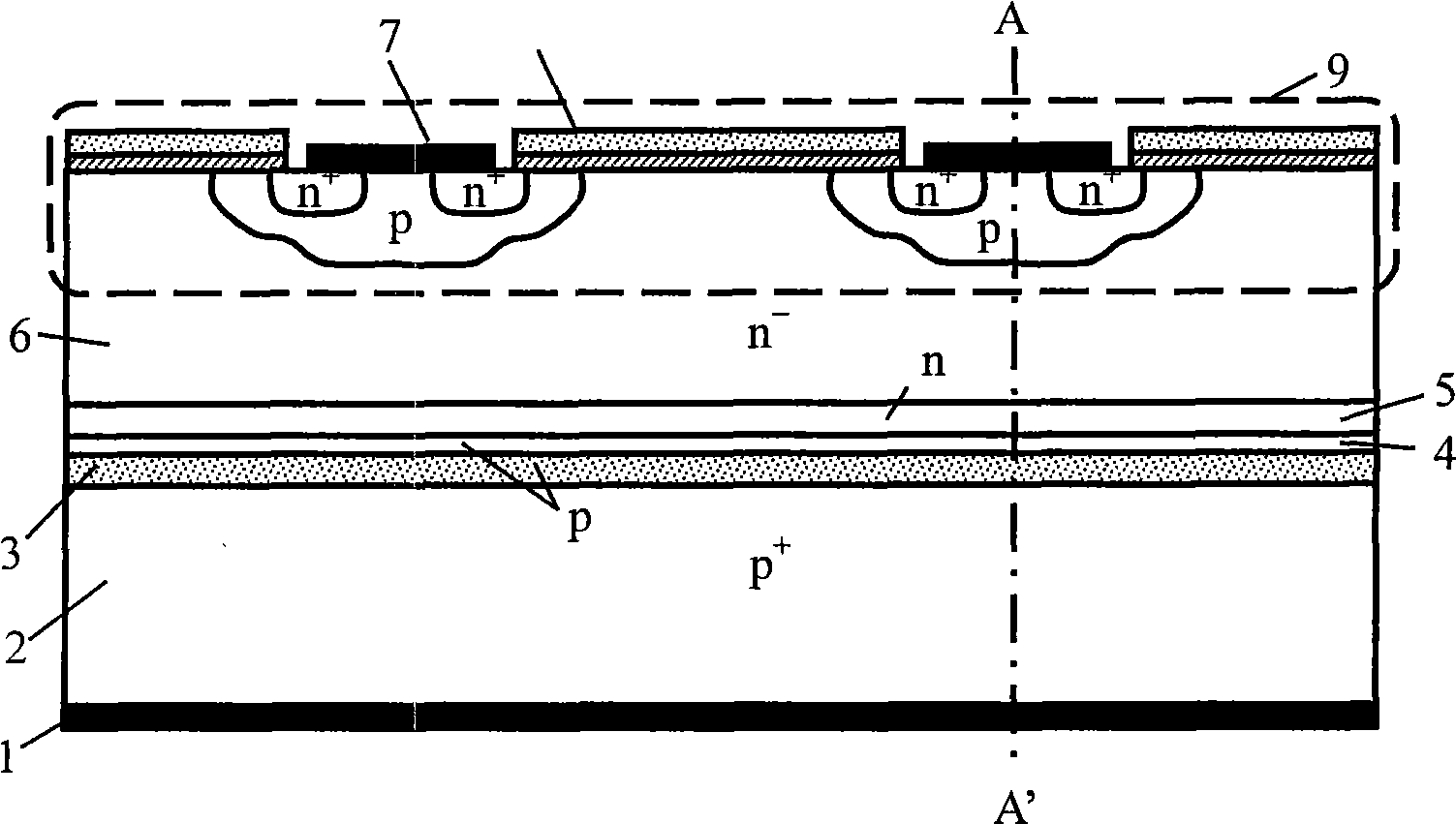

[0056] What is manufactured in this embodiment is a 600V plane gate transparent collector IGBT silicon device. According to manufacture method and step of the present invention (see figure 2 ) step by step, you can manufacture such as figure 1 The final structure shown. The specific process and its key parameters are as follows.

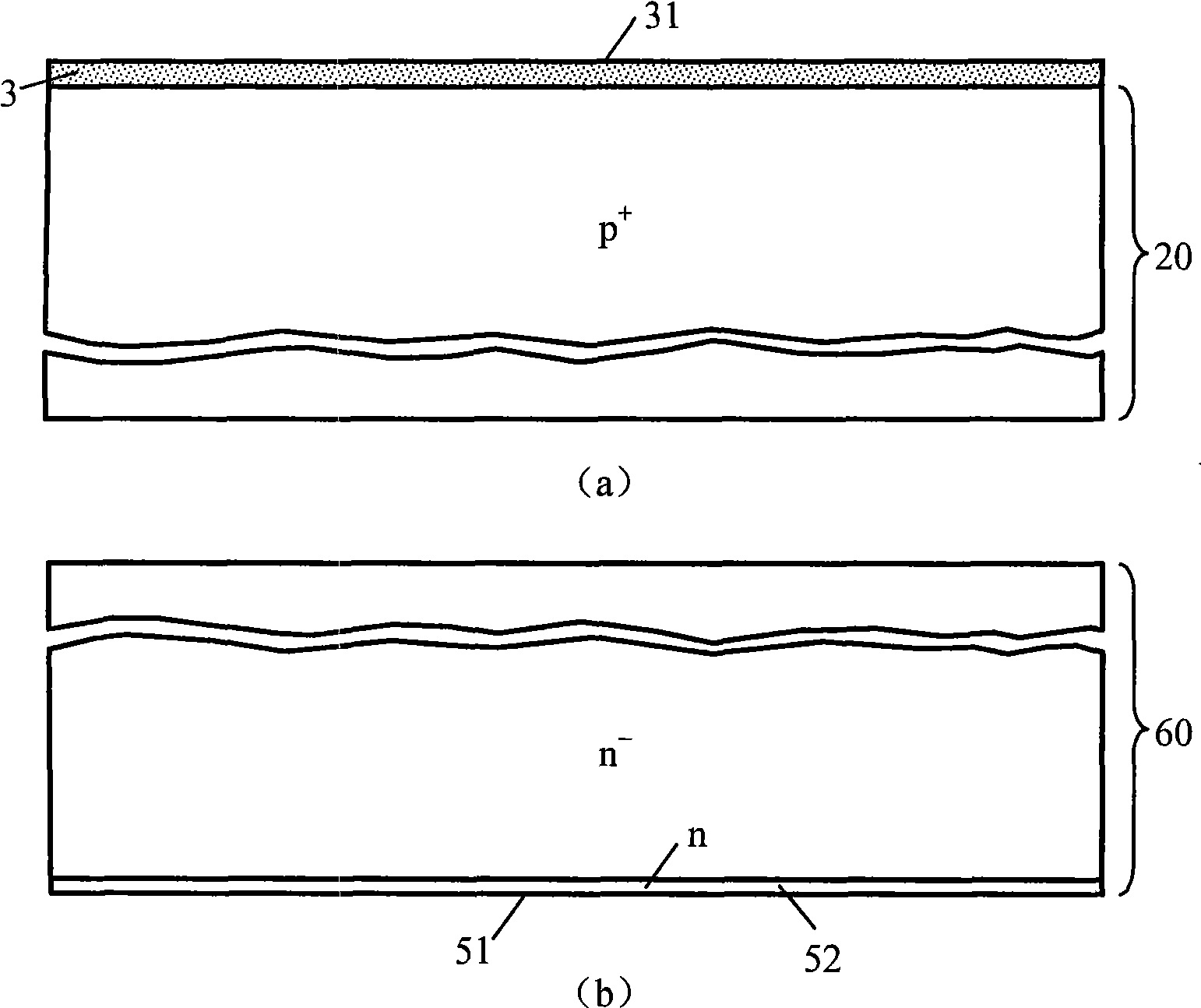

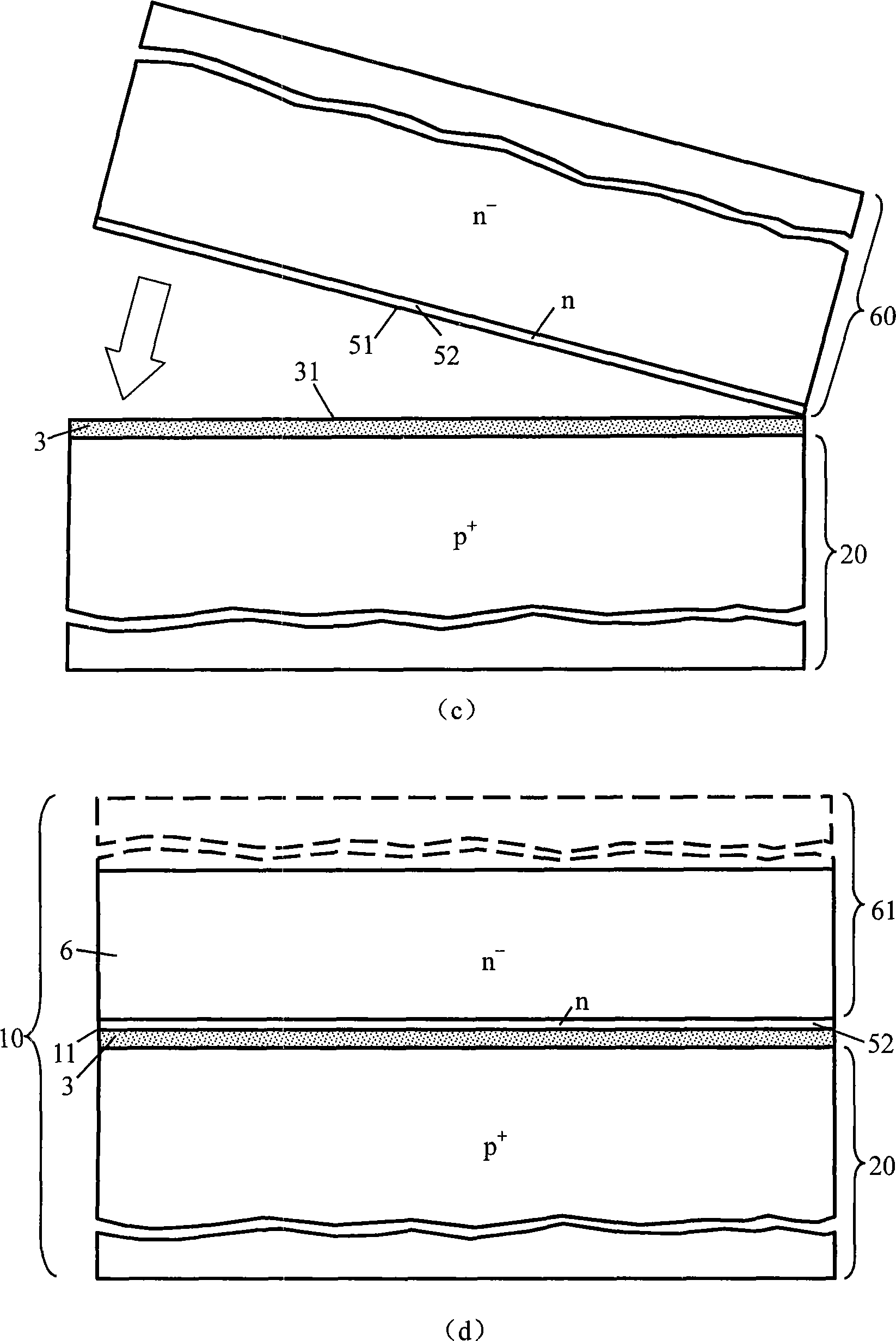

[0057] In the first step, the boron doping concentration is selected to be 7.5×10 18 cm -3 , p with a thickness of 500-600 μm + Monocrystalline silicon substrate 20, and a layer of undoped polycrystalline silicon layer 3 is grown on the upper surface by silane thermal decomposition LPCVD method, the growth temperature is 625°C, and the thickness is controlled at about 1 μm. see figure 2 (a).

[0058] The second step, such as figure 2 As shown in (b), another choice of phosphorus doping concentration is 7×10 13 cm -3 the n - Silicon single wafer 60, the n - A thin layer of SiO is thermally grown on the lower surface 51 of the wafer 2 S...

Embodiment 2

[0066] What is manufactured in this embodiment is a 600V trench-gate transparent collector IGBT silicon device. The manufacturing steps and related material parameters and process parameters are basically the same as those in Embodiment 1, except that the planar gate process is changed to the current common trench gate process when implementing step 5 to manufacture a power MOS structure. The resulting structure can be found in Figure 4 .

[0067] What is produced is a 600V trench gate internal transparent collector IGBT with good performance, which does not require ultra-thin sheet processing, and has a positive temperature coefficient of on-state voltage (two I at room temperature and high temperature) C -V CEsat The current at the intersection point of the conduction characteristic curve is lower than half of the rated current). When the cell shape, size and density of the surface power MOS structure are the same or similar, the internal transparent collector IGBT can o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com